Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Infrared Lamp Board Is Monitoring Camera

2022-12-14

Tianhui

43

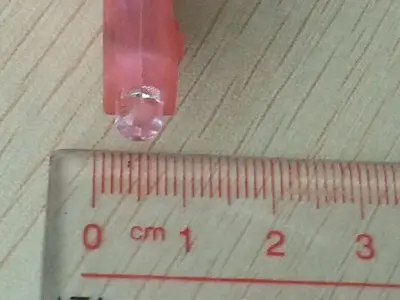

The infrared lamp board has a key role in monitoring the camera. Below, the editor of the infrared lamp board will explain the process of the infrared lamp board. 1. Preparation of raw materials, engineer design plan PCB, and then submit to PCB manufacturers printed circuit board. Then the purchase of raw materials, including resistance, diode, triode, etc. 2. Perform HSMT or SMT, HSMT refers to handmade patch, SMT refers. 3. The selection of infrared lights should be selected according to the needs of the plan. 4. Over -lead furnace, also known as reflux welding. It uses the principle of contraction when the hot -melt tin encounters the gap of copper band. Before the current flow welding, there is no need to insert an infrared light or light -sensitive resistance site. The power supply and inserted position should be sticking with high temperature adhesive paper. 5. The next is DIP, that is, the plug -in. When inserting the selected LED infrared lights on the PCB board, the positive and negative pole of the LED infrared lamp must be distinguished (you can distinguish the positive and negative poles through the PN in the PN in the LED infrared lamp, the larger one is the negative electrode, and the small one is the positive pole). 6. Over -welded welding, put a board on both ends of the machine, and one person to collect the board. Employees must bring protective gloves to prevent scald during operation. Placing an ionic fan at the outlet. anti-static. 7. The cutting of the DIP plug -in is divided into hand -cut and foot cutting feet. At this time, you must pay attention to the position of the cut. Do not be too long, so that it is easy to fold your feet during transportation and cause short circuits, and you should not be too short. Considering the protection of electronic devices such as triode pipes. In the process of cutting their feet, employees must bring goggles to prevent debris splashes for eyes. 8. Visual inspection, mainly check whether the process process is correct, whether the electronic devices are inserted or wrong, whether the tin points are qualified, and the tin points are unqualified to replenish welding. 9. Put on power supply and inserted foot. 10. Install the light -sensitive resistance, you must first put the plastic cover of the light resistance, and then install the infrared lamp plate. 11. Second inspection, link power supply, check whether the lights are bright, whether the light -sensitive resistance plays a role, picked out the bad products. 12. Washing boards are divided into artificial laundry and machine washing. Because there are many residual lead slag on the infrared lamp plate, etc. The proportion of laundry water should be appropriate, and the time of soaking must be controlled. The speed of the laundering machine must be controlled, otherwise it will easily hurt the circuit board. After the machine washed Washing it will be washed with a toothbrush and washed on handwashing water. 13. Drying, pay attention to the temperature of the dryer. If the temperature is too high, the tin lead will fall; too low, the effect of not drying. 14. Filter filter. 15. After the QC test, it is mainly whether TEST can work normally. 16. Aging (the conventional is 72 hours). 17. Inspection, under the aging of infrared lamps, inspections must be inspected every two hours, and the inspection record is done. 18. After the aging is over, check again, the infrared lamp board process process is completed.

Author: Tianhui-Air Disinfection

Author: Tianhui-UV Led manufacturers

Author: Tianhui-UV water disinfection

Author: Tianhui-UV LED Solution

Author: Tianhui-UV Led diode

Author: Tianhui-UV Led diodes manufacturers

Author: Tianhui-UV Led module

Author: Tianhui-UV LED Printing System

Author: Tianhui-UV LED mosquito trap

GET IN TOUCH WITH Us

recommended articles

As summer approaches, so does the pesky problem of mosquitoes. These tiny insects can ruin a peaceful outdoor evening, leaving us with itchy bites and disease risk. Fortunately, there's a solution in the form of UV LED mosquito traps. These devices use the power of ultraviolet light to attract mosquitoes and other flying insects better.

no data

Contact Us

You can find us here

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service

We use cookies to ensure that we give you the best experience on and off our website. please review our privacy policy

Reject

Cookie Settings

Agree Now

Your basic information, online operation behaviors, transaction information, access data are necessary to offer you our normal purchase, transaction, and delivery services. Withdrawal of this authorization will result in the failure of shopping or even paralysis of your account.

Your basic information, online operation behaviors, transaction information, access data are of great significance to improve website construction and enhance your purchase experience.

Your basic information, online operation behaviors, transaction information, preference data, interaction data, forecasting data, and access data will be used for advertising purposes by recommending products more suitable for you.

These cookies tell us how you use the site and help us to make it better. For example, these cookies allow us to count the number of visitors to our website and know how visitors move around when using it. This helps us to improve how our site works. For example, by ensuring that users find what they are looking for and that the loading time of each page is not too long.