Tianhui- daya daga cikin manyan UV LED guntu masana'antun da kuma masu kaya bayar da ODM / OEM UV jagoranci guntu sabis na kan 22+ shekaru.

Infrared Lamp Board Yana Kula da Kyamara

2022-12-14

Tianhui

43

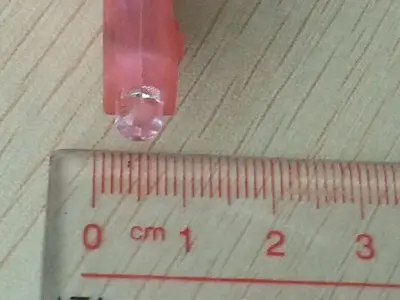

Jirgin fitilar infrared yana da muhimmiyar rawa wajen lura da kyamara. A ƙasa, editan fitilar fitilar infrared zai bayyana tsarin tsarin fitilar infrared. 1. Shiri na albarkatun kasa, injiniyan ƙira shirin PCB, sa'an nan kuma sallama zuwa PCB masana'antun buga kewaye allon. Sa'an nan kuma sayan albarkatun kasa, ciki har da juriya, diode, triode, da dai sauransu. 2. Yi HSMT ko SMT, HSMT na nufin facin hannu, SMT yana nufin. 3. Ya kamata a zaɓi zaɓin fitilun infrared bisa ga bukatun shirin. 4. Sama da gubar tanderu, kuma aka sani da reflux walda. Yana amfani da ƙa'idar ƙaddamarwa lokacin da tin mai zafi ya ci karo da tazarar bandejin jan karfe. Kafin waldawar mai gudana na yanzu, babu buƙatar saka hasken infrared ko wurin juriya mai saurin haske. Samar da wutar lantarki da matsayi da aka saka ya kamata ya kasance mai mannewa tare da takarda m zafin jiki. 5. Na gaba shine DIP, wato, plug-in. Lokacin shigar da zaɓaɓɓen fitilun infrared LED akan allon PCB, dole ne a bambanta madaidaicin sandar infrared na infrared na LED (zaku iya bambanta sanduna masu kyau da mara kyau ta hanyar PN a cikin PN a cikin fitilar infrared LED, wanda ya fi girma shine. na'urar lantarki mara kyau, kuma ƙarami ita ce sandararriyar sanda). 6. Welding over-welded, sanya allo a kan ƙarshen injin ɗin, da mutum ɗaya don tattara allon. Dole ne ma'aikata su kawo safar hannu masu kariya don hana ƙonewa yayin aiki. Ajiye fan na ionic a wurin fita. anti-static. 7. An raba yankan filogin DIP zuwa ƙafar yankan hannu da ƙafa. A wannan lokacin, dole ne ku kula da matsayi na yanke. Kada ku yi tsayi da yawa, don haka yana da sauƙi don ninka ƙafafu yayin sufuri da kuma haifar da gajeren da'ira, kuma kada ku kasance gajarta. Yin la'akari da kariyar na'urorin lantarki irin su bututun triode. A yayin yanke ƙafafu, dole ne ma'aikata su kawo tabarau don hana tarkacen idanu. 8. Duban gani, galibi bincika ko tsarin aikin daidai ne, ko an saka na'urorin lantarki ko kuskure, ko abubuwan da suka dace sun cancanta, da makin kwano ba su cancanci sake cika walda ba. 9. Saka wutar lantarki da kafa kafa. 10. Shigar da juriya mai haske, dole ne ka fara sanya murfin filastik na juriya na haske, sannan shigar da farantin fitilar infrared. 11. Dubawa na biyu, haɗin wutar lantarki, duba ko fitilu suna da haske, ko haske - juriya mai mahimmanci yana taka rawa, ya fitar da samfurori mara kyau. 12. An raba allon wanki zuwa wanki na wucin gadi da wankin injin. Domin akwai ragowar gubar da yawa akan farantin fitilar infrared, da sauransu. Yawan ruwan wanki ya kamata ya dace, kuma lokacin jiƙa dole ne a sarrafa shi. Dole ne a sarrafa saurin injin wanki, in ba haka ba zai cutar da allon kewayawa cikin sauƙi. Bayan an wanke inji Ana wanke shi da buroshin hakori a wanke akan ruwan wanke hannu. 13. Drying, kula da yawan zafin jiki na bushewa. Idan zafin jiki ya yi yawa, gubar kwano za ta faɗi; ƙananan ƙananan, sakamakon rashin bushewa. 14. Tace. 15. Bayan gwajin QC, galibi shine ko TEST na iya aiki akai-akai. 16. Tsufa (na al'ada shine 72 hours). 17. Binciken, a ƙarƙashin tsufa na fitilun infrared, dole ne a duba dubawa kowane sa'o'i biyu, kuma an yi rikodin binciken. 18. Bayan tsufa ya ƙare, sake dubawa, an kammala tsarin aikin allon fitilar infrared.

Mawallafi: Tianhui - Ru’uwan ƙaru

Mawallafi: Tianhui - Masu aikin UV Led

Mawallafi: Tianhui - Ruwi

Mawallafi: Tianhui - UV LED

Mawallafi: Tianhui - UV LED diode

Mawallafi: Tianhui - Masu aiki a UV Led diodes

Mawallafi: Tianhui - Alƙalata UV

Mawallafi: Tianhui - UV LED

Mawallafi: Tianhui - UV LED

Shiga tare da mu

Labarin da aka ba da shawarar

Wace tafi da UV LED ta fi kyau don amfani da hakori? Da kyau, ya dogara da aikin: 405m don ciring da farin ciki da 275nm don kamuwa da haifuwa da haifuwa. Dukansu suna yin aiki mai ban mamaki; Kuna buƙatar zaɓar cikin hikima. Kuma idan kuna son inganci mai kyau, amintacce da kuma ingantacce UV LEDs? Tianhui UV LED ya dawo da baya. Kuna iya taimaka wa more hakori masu hakori suna murmushi tare da fasahar mu, aiyukan duniya da kulawa da abokin ciniki.

Vitamin D shine abin da jikinku yake buƙatar ƙarfi, yana jin daɗi da kuma ci gaba da cuta. Ba duk mutane bane, duk da haka, samun dama don ciyar da lokaci mai yawa a ƙarƙashin rana. Wannan shine shine hasken UVB na UVB. Yana ba da fata tare da haɓaka mai kyau don zai iya samar da bitamin d a daidai yadda yake a rana. Kuma kamar yadda jikinka yake samar da karin bitamin D, to zai iya ɗaukar ƙarin alli, ku kiyaye tsarin garkuwar rigakafi har ma ya sa ku ji wuta.

Ƙura na iya zama ƙanana, amma matsalolin da ke haifar da girma. Wancan’S Me yasa ainihin abubuwan ganowa. Take kwayoyin halittar kai tare da Fasahar 365NM UV LED Fasahar da ta fi sauki fiye da da. Saboda waɗannan leds sune ingantaccen ƙarfin kuzari, lafiya da daidaito, suna cikakke don amfani a tsarin gano ƙura na zamani.

Don ruwa mai tsabta, abin da kuke buƙata shi ne wani abu mai dogaro, lafiya da dacewa. Makamashin UV na UV LED ya cancanci wannan lamari daidai. Suna ba da sunadarai, sauri, da tsarkakewa ba tare da ɗaukar sarari da yawa ko iko ba. Su’Re kuma nan gaba, yana yin su babban zaɓi na gidajen zamani da birane masu wayo.

Gano gano kayan aiki ne mai ƙarfi don ganin abin da zai iya’t a gani. Da 365nm UV LEDs suna yin kayan aiki har ma da kyau. Amfani da LEDs ya fi dacewa, mafi aminci kuma mafi sauki fiye da yadda aka danganta da fitilun gargajiya. Ko da kuwa makasudin shine neman matsala a cikin samfurin, warware laifi ko gwajin ruwa, yana taimakawa wajen yin abin da yake da muhimmanci a gani.

Gresh suna Sneaky amma 275nm UV LEDs suna da ƙarfi. Suna taimakawa dakuna marasa rai, kayan aikin, da iska da sauri, lafiya, kuma ba tare da amfani da digo na ruwa ba. Shi’s ba mamaki su’Sake zama Go-don tsaftace, wuraren da ke da germ. Daga asibitoci zuwa gidaje, wannan fasaha tana haske mai haske.

Babu bayanai

Tuntube Mu

Tuniya na sauriwa

Za ka iya sami Mu

Tuntube mu

Barin bincikenku, za mu samar muku da kayan inganci da ayyuka!

Customer service

We use cookies to ensure that we give you the best experience on and off our website. please review our takardar kebantawa

Reject

Saitunan Cookie

Yarda yanzu

Bayanin ka na asali, halayen aikin kan layi, bayanin ma'amala, bayanan samun dama suna wajaba don ba ku siyanmu na al'ada, ma'amala, da sabis na isarwa. Cire wannan izinin zai haifar da gazawar siyayya ko ma inna na asusunka.

Bayanin asali, halayen aikin kan layi, bayanin ma'amala, bayanan samun damar suna da matukar muhimmanci don inganta shafin yanar gizon da haɓaka kwarewar siyanka.

Bayanin asali, halayen aikin kan layi, bayanin ma'amala, za a yi amfani da bayanan bayanan, da bayanan da aka fi dacewa da su don samfuran tallace-tallace da suka dace da ku.

Waɗannan kukis suna gaya mana yadda kuke amfani da shafin kuma taimaka mana mu ƙara shi. Misali, wadannan kukis suna ba mu damar ƙididdige yawan baƙi zuwa rukunin yanar gizon mu kuma sun san yadda baƙi ke motsawa yayin amfani da shi. Wannan yana taimaka mana don inganta yadda shafin yanar gizon mu. Misali, ta tabbatar da cewa masu amfani sun gano abin da suke nema kuma lokacin da ake neman kowane shafi ba tsayi ba.