I-Tianhui- enye yeenkokeli ezikhokelayo ze-UV ze-chip ze-UV kunye nababoneleli babonelela ngenkonzo yetshiphu ye-ODM/OEM UV ye-LED ngaphezulu kweminyaka engama-22+.

Ibhodi yesibane se-infrared yiKhamera yokuHlola

2022-12-14

Tianhui

43

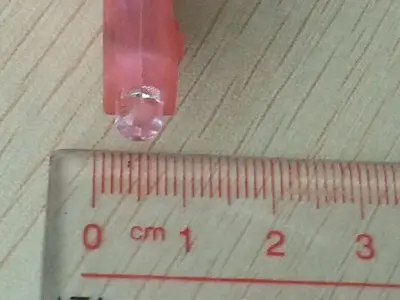

Ibhodi yesibane se-infrared inendima ephambili ekubekeni iliso kwikhamera. Ngezantsi, umhleli webhodi yesibane se-infrared uya kuchaza inkqubo yebhodi yesibane se-infrared. 1. Ukulungiswa kwezinto ekrwada, isicwangciso uyilo injineli PCB, uze ungenise kubenzi PCB eprintiweyo ibhodi yesekethe. Emva koko ukuthengwa kwezinto eziluhlaza, kuquka ukuchasana, i-diode, i-triode, njl. 2. Yenza i-HSMT okanye i-SMT, i-HSMT ibhekisa kwiphetshi eyenziwe ngesandla, i-SMT ibhekisa. 3. Ukukhethwa kwezibane ze-infrared kufuneka kukhethwe ngokweemfuno zesicwangciso. 4. I-Over-lead furnace, ekwabizwa ngokuba yi-reflux welding. Isebenzisa umgaqo wokunqanda xa i-hot-melt tin idibana nomsantsa webhendi yobhedu. Ngaphambi kokuhamba kwe-welding yangoku, akukho mfuneko yokufaka ukukhanya kwe-infrared okanye indawo yokumelana nokukhanya. Unikezelo lwamandla kunye nendawo efakiweyo kufuneka ibambelele ngephepha eliphezulu lokubambelela kwiqondo lokushisa. 5. Okulandelayo yi-DIP, oko kukuthi, iplagi-in. Xa ufaka izibane ezikhethiweyo ze-infrared ze-LED kwibhodi ye-PCB, isibane esilungileyo nesibi sesibane se-infrared kufuneka sahlulwe (uyakwazi ukwahlula iipali ezilungileyo nezingalunganga nge-PN kwi-PN kwisibane se-infrared LED, enkulu i-electrode engalunganga, kwaye encinci yipali echanekileyo). 6. Ukuwelda ngaphezulu, ubeke ibhodi kuzo zombini iziphelo zomatshini, kunye nomntu omnye wokuqokelela ibhodi. Abasebenzi kufuneka beze neglavu zokukhusela ukuthintela ukutshisa ngexesha lokusebenza. Ukubeka i-ionic fan kwindawo yokuphuma. anti-static. 7. Ukusikwa kweplagi ye-DIP-in ihlulwe kwi-hand-cut and foot cut foot. Ngeli xesha, kufuneka ubeke ingqalelo kwindawo yokusika. Musa ukuba mde kakhulu, ukwenzela ukuba kube lula ukugoba iinyawo zakho ngexesha lokuthutha kwaye kubangele imijikelezo emfutshane, kwaye akufanele ube mfutshane kakhulu. Ukuqwalasela ukukhuselwa kwezixhobo zombane ezifana nemibhobho ye-triode. Kwinkqubo yokusika iinyawo zabo, abasebenzi kufuneka beze nezibuko zokuthintela ukuchaphaza kobutyobo emehlweni. 8. Ukuhlolwa okubonakalayo, ngokukodwa ukujonga ukuba inkqubo yenkqubo ichanekile, ingaba izixhobo zombane zifakiwe okanye zingalunganga, ukuba ngaba iinqununu ze-tin zifanelekile, kwaye iindawo ze-tin azifanelekanga ukuzalisa i-welding. 9. Beka umbane kunye nonyawo olufakiwe. 10. Faka ukuxhathisa ukukhanya, kufuneka uqale ubeke isigqubuthelo seplastiki sokumelana nokukhanya, uze ufake ipleyiti yesibane se-infrared. 11. Uhlolo lwesibini, ikhonkco unikezelo lwamandla, khangela ukuba izibane ziqaqambile, nokuba ukuchasana ukukhanya-sensitive kudlala indima, wakhetha iimveliso ezimbi. 12. Iibhodi zokuhlamba zohlulwe zibe yimpahla yokwenziwa kunye nokuhlamba ngoomatshini. Ngenxa yokuba zininzi intsalela ye-laad slag kwipleyiti yesibane se-infrared, njl. Umlinganiselo wamanzi okuhlamba impahla kufuneka ufanelekile, kwaye ixesha lokufunxa kufuneka lilawulwe. Isantya somatshini wokuhlamba kufuneka silawulwe, ngaphandle koko kuya kulimaza ngokulula ibhodi yesiphaluka. Emva kokuba umatshini uhlanjiwe Ukuhlamba kuya kuhlanjwa ngebrashi yamazinyo kwaye kuhlanjwe emanzini okuhlamba izandla. 13. Ukomisa, nikela ingqalelo kwiqondo lokushisa kwesomisi. Ukuba iqondo lokushisa liphezulu kakhulu, i-tin lead iya kuwa; iphantsi kakhulu, umphumo wokungomisi. 14. Isihluzi. 15. Emva kovavanyo lwe-QC, ikakhulu ukuba i-TEST inokusebenza ngokuqhelekileyo. 16. Ukuguga (okuqhelekileyo ziiyure ezingama-72). 17. Ukuhlolwa, phantsi kokuguga kwezibane ze-infrared, ukuhlolwa kufuneka kuhlolwe rhoqo kwiiyure ezimbini, kwaye irekhodi lokuhlola liyenziwa. 18. Emva kokuba ukuguga kuphelile, khangela kwakhona, inkqubo yebhodi yesibane se-infrared igqityiwe.

Umbhali: Tianhui- Isifo sokubulala umoya

Umbhali: Tianhui- Abavelisi be-UV Led

Umbhali: Tianhui- Isifo samanzi e-UV

Umbhali: Tianhui- Isisombululo se-UV LED

Umbhali: Tianhui- UV Led diode

Umbhali: Tianhui- Abavelisi be-UV Led diodes

Umbhali: Tianhui- Imodyuli ekhona

Umbhali: Tianhui- Inkqubo yokushicilela i-UV LED

Umbhali: Tianhui- Umgibe weengcongconi

Nxibelelana nathi

Amanqaku acetyiswayo

akukho datha

Qhagamshelana Nabo

Unxulumaniso olukhawulezayo

Ungayifumana Apha

Ukushicilela © Zhuhai Tianhui Electronic Co., Ltd www.tianhui-led.com |

Imephu yesiza

Qhagamshelana nathi

Shiya isicelo sakho, siya kukubonelela ngeemveliso kunye neenkonzo ezisemgangathweni!

Customer service

We use cookies to ensure that we give you the best experience on and off our website. please review our umthetho wabucala

Reject

Useto lwecookie

Vuma ngoku

Ulwazi lwakho olusisiseko, indlela yokuziphatha e-intanethi, ulwazi lwentengiselwano, idatha yokufikelela kuyimfuneko ukuthenga kwakho okuqhelekileyo, intengiselwano, kunye neenkonzo zokuhambisa. Ukurhoxiswa kwesi sigunyaziso kuya kubangela ukusilela ekutyeni okanye ukhubazekile kwiakhawunti yakho.

Ulwazi lwakho olusisiseko, indlela yokuziphatha e-intanethi, ulwazi lwentengiselwano, idatha yokufikelela ibaluleke kakhulu ekuphuculeni ukwakhiwa kwewebhusayithi nokuphucula amava akho okuthenga.

Ulwazi lwakho olusisiseko, indlela yokuziphatha e-intanethi, ulwazi lwentengiselwano, idatha yokhetho, idatha yonxibelelwano, idatha yophando, kunye nedatha yokufikelela iya kusetyenziselwa iinjongo zentengiso elungele wena.

Ezi kicokies zisixelela ukuba uyisebenzisa njani indawo kwaye usincede ukuba senze ngcono. Umzekelo, ezi kicokies zivumela ukubala inani leendwendwe kwiwebhusayithi yethu kwaye bayazi ukuba abatyeleli behamba njani xa beyisebenzisa. Oku kusinceda ukuba siphucule indlela esisebenza ngayo indawo yethu. Umzekelo, ngokuqinisekisa ukuba abasebenzisi bafumana into abayifunayo kwaye ixesha lokulayisha iphepha elinye alikho.