Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

How to Choose the LED Lamp Beads in the LED Display?

2022-10-09

Tianhui

101

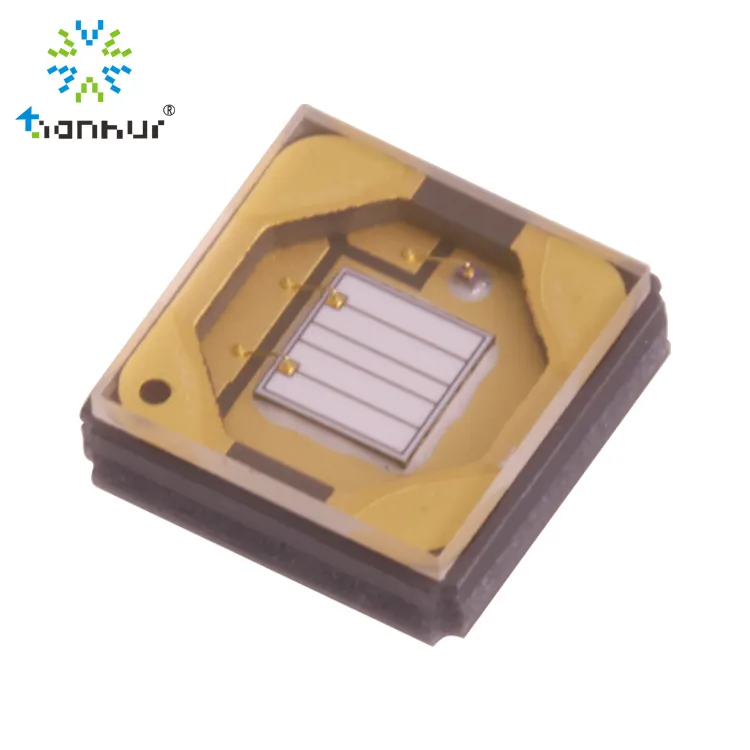

The important part of the LED display is LED lamp beads and LED unit boards. If any of them have problems, it will directly affect the overall quality of the LED display! So, how to distinguish the quality of LED lamp beads and LED unit boards is the quality of the LED and LED unit boards. The issues that LED display merchants care about, here is a common method for detecting the quality of LED lamp beads and PCB unit boards. I hope it will be helpful to the LED display merchants. In addition, the quality is the king. The product and device that refuses the cheap and shoddy is also the need to do by the manufacturer, so as not to damage the effect of the normal work and the unnecessary maintenance of the subsequent. LED unit board. Some LED unit board manufacturers use cheap flame retardant paper boards or single -sided fiber boards as the LED lamp as the LED lights for low prices. Because all glass fiber PCB boards are expensive. At the beginning, the difference can not be seen. Generally, if it is not one year, it will break due to moisture, ultraviolet destruction, oxidation, etc., causing the entire LED unit board to be scrapped. High -quality LED unit boards must be double -sided all -off glass fiber PCB board. Although the cost is high, the quality is guaranteed. Observe whether the brand of IC devices use is consistent. What model of IC and how many ICs are used, which is enough to affect the quality of the LED unit board. Some LED display manufacturers, in order to save costs, will deliberately reduce the number of ICs during the production unit board, or mixed with other brands of IC. Beads and chips. The naked eye cannot distinguish the quality of the lamp beads. It can only be based on long -term tests, that is, the aging test that experts say. The approach of the general LED display manufacturer is: power to power before the factory, check whether the LED display can operate normally, will not be tested for a long time. Because a lot of time and labor costs require a lot of time and labor costs. Welding quality: Check whether there are component leakage stickers, wrong stickers, and whether there are component tube feet and burrs short circuit. Check whether the direct plug -in welding joints are smooth and round, whether the board surface is clean and neat, and no virtual welding welding. Check the consistency of the flatness of the light and the color of the ink. Power -powered test: The consistency of the lighting point of the power -powered test; whether the power -on test is effectively protected by CEM4953;. The main material composition of LED lamp beads packaged includes brackets, chips, solid crystal gums, key lines and packaging gels, etc. SMD (Surface Mountain Devices) refers to the surface -packed packaging structure LED, which mainly include the LED (Chicled) and PLCC structures of the PCB board structure. Let s introduce some of the current domestic development status in the aspects of packaging materials. Role of a bracket. PLCC (Plastic Leaded Chip Carrier) bracket is the carrier of the SMD LED device, which plays a key role in the reliability and light of LED. The PLCC bracket production process mainly includes the processes of metal material bands, electroplating, PPA (polybinzide) injection molding, bending, five -sided three -dimensional inkjet and other processes. Among them, electroplating, metal substrates, plastic materials, etc. occupy the main cost of the bracket. The structure improvement design of the bracket. Because the PPA and metal binding are a physical binding, the gap will become larger after the high temperature return furnace, which makes it easy for water vapor to enter the device along the metal channel to affect the reliability of reliability. In order to improve product reliability to meet high -quality LED display devices that meet the needs of high -end market, some packaging factories have improved the structural design of the bracket, such as adopting advanced waterproof structure design, bending stretching and other methods to extend the water vapor of the bracket into the path entering the path into the path. At the same time, multiple waterproof measures such as waterproof tanks, waterproof steps, and waterproof holes are added inside the bracket. This design not only saves packaging costs, but also improves product reliability. At present, it has been widely used in outdoor LED display products. After being packed and normal brackets to test the qi of the LED bracket designed by SAM (Scanning Acrentic Microscope). The LED chip is the core of LED lamp beads, and its reliability determines the life and luminous performance of LED lamp beads and even LED display. The cost of LED chip accounts for the total cost of LED device is also very large. With the decrease in cost, the size of the LED chip has become smaller and smaller, and it also brings a series of reliability issues. With the reduction of the size, the PAD of the P electrode and the N electrode also narrowed. The reduction of the electrode PAD directly affects the quality of the welding line. At the same time, the distance A between the two PADs will also shrink, which will cause the electrode current to excessively increase the current density, the current gathers locally at the electrode. Excessive high, uneven brightness, easy leakage, electrode drop, and even low light efficiency, etc., eventually led to the reduction of the reliability of the LED display. The key line is one of the key materials for LED packaging. Its function is to realize the electrical connection of the chip and pins, which plays the role of chip and the outside world. LED device encapsulates common key lines including gold, copper wires, copper -plated copper lines, and alloy lines, etc. (1) Goldline. The golden line is widely used, the process is mature, but the price is expensive, resulting in the high cost of LED's packaging. (2) Copper thread. Copper threads have the advantages of cheap, good heat dissipation effects, and slow growth of metal intervertebral compounds during the welding line. The disadvantage is that copper is easy to oxidize, high hardness, and high strain intensity. Especially in the heating environment of the keyhearted copper roasted ball, the surface of the copper surface is very easy to oxidize, and the formed oxide film reduces the albuming performance of the copper wire. This proposes higher requirements for the process control in the actual production process. (3) Plating 线 copper wire. In order to prevent the oxidation of copper wires, the copper -plated copper wire gradually attracted the attention of the packaging industry. The advantages of high mechanical strength, moderate hardness, well -welded and so -sized sphere are suitable for high -density, multi -footed integrated circuit packaging. At present, the glue encapsulated by the LED display device mainly includes two types of epoxy resin and silicon silicon. (1) epoxy resin. Epoxy resin is prone to aging, easy to be damp, heat -resistant, and is easy to change color at short -wave light and high temperature. It has a certain toxicity in the state of glue. The thermal stress does not match the LED. Therefore, epoxy resin is usually offensive. (2) Organic silicon. Compared with epoxy resin, organic silicon has a high cost -effectiveness, excellent insulation, dielectricity, and closeness. But the disadvantage is that the gas tightness is poor, and it is easy to suck. So it is rarely used in the packaging application of the LED display device. Transfer from [Soso LED Network] [Tags in this article] Patching LED Lighting Drink Lighting Bead LED Lighting Bead Manufacturer LED Lighting Drives Vehina Polar Tube [Responsible Editor]

Author: Tianhui-Air Disinfection

Author: Tianhui-UV Led manufacturers

Author: Tianhui-UV water disinfection

Author: Tianhui-UV LED Solution

Author: Tianhui-UV Led diode

Author: Tianhui-UV Led diodes manufacturers

Author: Tianhui-UV Led module

Author: Tianhui-UV LED Printing System

Author: Tianhui-UV LED mosquito trap

GET IN TOUCH WITH Us

You can find us here