Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

CICS Related Issues of UV Glue Curing Oxygen Obstruction

2022-11-08

Tianhui

66

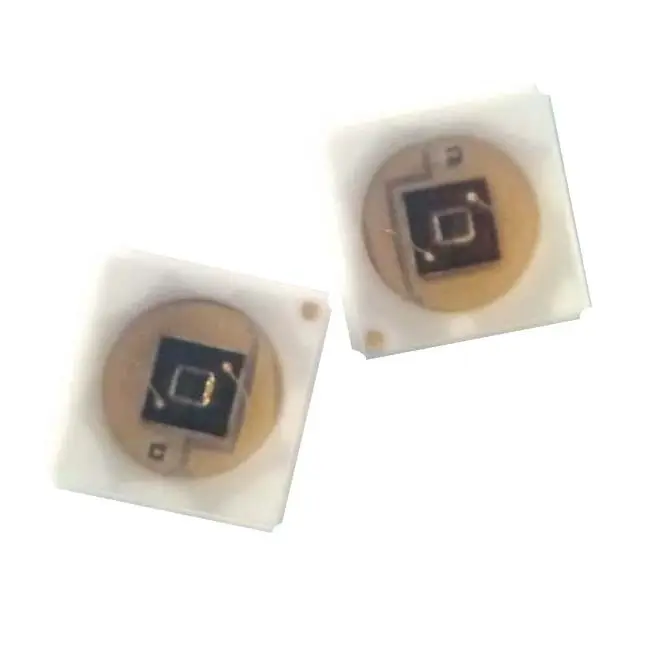

Now when we do glue testing for customers, we will encounter the use of UVLED devices to irradiate and solidively, and it will be a bit sticky to touch the surface of the glue with our hands. In the inside of cutting and curing glue, we can see that the glue is completely solidified after the glue is shot with the UVLED light. Why do you have such an imagination? This has extended an important problem in the UVLED curing industry. UV glue is the problem of oxygen resistance when curing up with UVLED device. Oxygen closure is a common problem in the reaction of optical curing. In the UVLED optical reaction, the free radicals generated by the cracked light cause of the light cause will be captured by oxygen to form peroxic free radicals. The problem. The method of overcoming oxygen blocking can be divided into two types: chemical and physical methods. The method of inert gas used in physical methods to isolate oxygen is a very effective method. The commonly used inert gases are usually nitrogen, or sorbe. The cost of nitrogen and gaseous gas is relatively high, and the other inert gas that can be used is carbon dioxide. The use of carbon dioxide has some advantages that other gases do not have: First, carbon dioxide is easy to obtain, and the cost is low. Secondly, because carbon dioxide is heavier than air, it is easy to maintain in the container, so that there will be less loss.

Author: Tianhui-Air Disinfection

Author: Tianhui-UV Led manufacturers

Author: Tianhui-UV water disinfection

Author: Tianhui-UV LED Solution

Author: Tianhui-UV Led diode

Author: Tianhui-UV Led diodes manufacturers

Author: Tianhui-UV Led module

Author: Tianhui-UV LED Printing System

Author: Tianhui-UV LED mosquito trap

GET IN TOUCH WITH Us

recommended articles

In the food and beverage industry, ultraviolet (UV) disinfection technology is a rapidly expanding sector. UV radiation is used to disinfect water, air, and surfaces by killing bacteria, viruses, and other pathogens to make the food healthy. This technology has grown in popularity due to its efficiency, usability, and minimal cost.

As summer approaches, so does the pesky problem of mosquitoes. These tiny insects can ruin a peaceful outdoor evening, leaving us with itchy bites and disease risk. Fortunately, there's a solution in the form of UV LED mosquito traps. These devices use the power of ultraviolet light to attract mosquitoes and other flying insects better.

Are you aware of the latest findings on the transmission rate of the new coronavirus? A recent study has uncovered a shocking discovery- the air transmission rate of the virus may be a staggering 1,000 times that of the contact surface! This means the virus may spread faster and farther than we previously thought. Keep reading to learn more about this groundbreaking research and what it means for our fight against the pandemic.

Are you looking for a robust and flexible solution to disinfect your space? Look no further than mobile UV units. These innovative robots move from room to room, eliminating harmful germs and bacteria on surfaces. Mobile UV led diodes are becoming popular as more industries outside of healthcare catch on to the benefits of UV disinfection.

With The Recovery of Demand In The Pet Market, What Bright Spots Can UV LED Bring To The Pet Market?

UV LED, also known as Ultraviolet Light Emitting Diodes, is a solid-state device that produces light as soon as you pass electrical currents in a circuit. These currents pass from the positive side to the negative side of a current.

With the advancement of bright light transmitting diodes, the modern restoring market is rapidly developing (UV LEDs). They give various benefits over mercury fume and other UV light sources that are practically identical in certain applications, including fewer support costs, more prominent reliability, low intensity, further developed power control, and, obviously, cost reserve funds.

no data

Contact Us

You can find us here

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service

We use cookies to ensure that we give you the best experience on and off our website. please review our privacy policy

Reject

Cookie Settings

Agree Now

Your basic information, online operation behaviors, transaction information, access data are necessary to offer you our normal purchase, transaction, and delivery services. Withdrawal of this authorization will result in the failure of shopping or even paralysis of your account.

Your basic information, online operation behaviors, transaction information, access data are of great significance to improve website construction and enhance your purchase experience.

Your basic information, online operation behaviors, transaction information, preference data, interaction data, forecasting data, and access data will be used for advertising purposes by recommending products more suitable for you.

These cookies tell us how you use the site and help us to make it better. For example, these cookies allow us to count the number of visitors to our website and know how visitors move around when using it. This helps us to improve how our site works. For example, by ensuring that users find what they are looking for and that the loading time of each page is not too long.