Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Okay, Purple Light Beads, Okay

2022-11-18

Tianhui

59

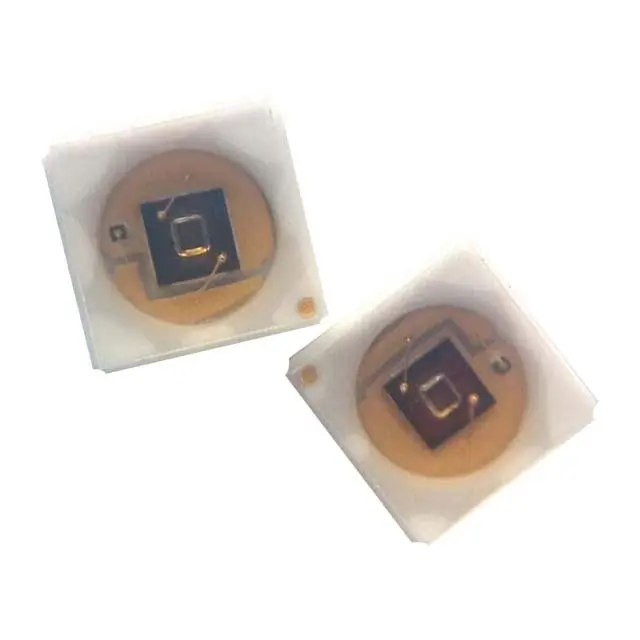

In 2016, the science and technology research and development team achieved good results in the high cost performance of the inverted COB light source. From the perspective of the packaging process, the brackets used by the COB light source have many sizes. Dozens of brackets, their materials are mainly aluminum, and there are copper and ceramic brackets. Generally, there are no side. The brackets used in integrated LED lamp beads are only 10W, 100W, 500W and other square brackets. The materials are mainly copper, and the brackets have 2 side feet. LED is a solid semiconductor device, which can directly convert electricity into light. LED is the third -generation lighting technology after incandescent lamps and fluorescent lamps. It has the characteristics of energy saving, environmental protection, safe and reliable. The purple light beads realize the inverted COB street lamp model. The CRI> 80 light effect exceeds 190LM/W, and can be produced in batches. It is at the forefront of the industry. This product is the best choice for high -end products manufacturing. At present, its main application venues are probably these: Since LED is a flat glowing body, its light effect is as high as 120LM/W, which is much higher than the 100LM/W of 70LM/W of ordinary fluorescent lamps and the T5 lamps. Higher light effect. As we all know, the quality of LED chips has a great impact on the quality of downstream packaging or terminal products. Customers have higher requirements for the consistency, stability, and light decay of LED chips. Hua Chan has always maintained the continuous innovation and optimization of product technology, reaching the international first -class technology level, and obtained the recognition of mainstream customers in the industry. Purple light bead monomer architecture, historical building group exterior wall lighting, light and outer transplantation of the building, indoor local lighting, green landscape lighting, advertising card lighting, medical culture and other special facilities lighting, bars, ballroom and other entertainment venue atmosphere lighting, etc. The chip electrical surface connected to the substrate connection through the golden thread bond facing up, and the electrical surface of the pouring chip facing down is equivalent to turning the former over, so it is called it“Inverted chip”The corresponding packaging process is called“Inverted process”. There are two ways to achieve high -power LED lighting: one is to encapsulate a single high -power LED chip, and the other is to use multi -chip integration packaging. For the former, with the development of chip technology, the size increases and the quality is improved, high -power LEDs can be achieved through large current drivers, but at the same time, it will be limited by chip size. The latter has greater flexibility and development potential. The number of chips can be changed according to different illuminations. At the same time, it has a high cost performance, making LED integration packaging into one of the mainstream directions for LED packaging. Since 2009, in order to break through the monopoly of foreign manufacturers for this field, Xiong Daxi led the team with the strong support of the Chinese Academy of Sciences, Jiangsu, Suzhou, and high -tech zones, focusing on the research and development and industrialization of special LED light sources. In terms of R & D design and manufacturing technologies, we have focused on research and development and separate approaches, and have achieved major breakthroughs. Purple light beads LED inverted gold -wire chip -level packaging. Based on the inverted chip technology, based on the traditional chip format packaging, the golden wire welding line technology is reduced, leaving only chips and glows with fluorescent powder and other uses.

Author: Tianhui-Air Disinfection

Author: Tianhui-UV Led manufacturers

Author: Tianhui-UV water disinfection

Author: Tianhui-UV LED Solution

Author: Tianhui-UV Led diode

Author: Tianhui-UV Led diodes manufacturers

Author: Tianhui-UV Led module

Author: Tianhui-UV LED Printing System

Author: Tianhui-UV LED mosquito trap

GET IN TOUCH WITH Us

recommended articles

The UV light utilized nowadays is traditionally produced by UV lamps based on mercury vapor for numerous industrial and medicinal uses. It has long been established that certain UV light waves have a severe germicidal effect, causing irreparable damage to DNA and RNA in microorganisms like viruses, bacteria, and fungi.

no data

Contact Us

You can find us here

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service

We use cookies to ensure that we give you the best experience on and off our website. please review our privacy policy

Reject

Cookie Settings

Agree Now

Your basic information, online operation behaviors, transaction information, access data are necessary to offer you our normal purchase, transaction, and delivery services. Withdrawal of this authorization will result in the failure of shopping or even paralysis of your account.

Your basic information, online operation behaviors, transaction information, access data are of great significance to improve website construction and enhance your purchase experience.

Your basic information, online operation behaviors, transaction information, preference data, interaction data, forecasting data, and access data will be used for advertising purposes by recommending products more suitable for you.

These cookies tell us how you use the site and help us to make it better. For example, these cookies allow us to count the number of visitors to our website and know how visitors move around when using it. This helps us to improve how our site works. For example, by ensuring that users find what they are looking for and that the loading time of each page is not too long.