Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

What Are the Principles and Characteristics of Dark Ultraviolet LED Lamp Beads?

2022-12-04

Tianhui

42

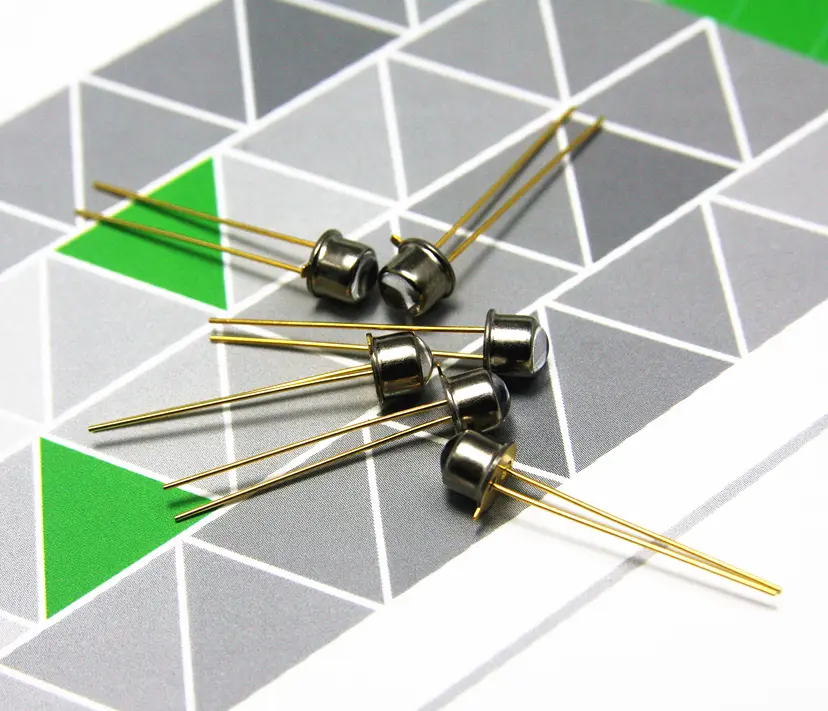

DUVLED lamp beads "> Duvled beads principle and characteristics 1. The lighting mechanism of duvled lamp beads: The end voltage of the PN knot forms a certain potential barrier. Zi is scattered with each other. Because the electronic migration rate is far greater than the relocation rate of the cave, a large number of electronic distribution will appear in the P area, and a small amount of carrier is formed in the P area. This type of electronics is compounded on the cave on the price, and the energy is released through the way of light energy. That is, the principle of PN hair lighting. DUVLED lamp line light source curing equipment DUV lamp bead line light source curing equipment 2. DUV lamp bead light emitting power: usually called external quantum power of the component. The internal quantum power of the component is originally the photoelectric conversion power of the component itself. First of all, it involves the characteristics of the component itself (such as being able to bring, defects, impurities, etc.), and the structure and structure of the component itself. However, the energy from the component refers to the photon generated inside the component. After the absorption, refraction, and reflection of the component itself, the number of photons performed outside the component can be measured in the actual operation. Therefore, the influencing factors of removing power include the absorption rate of the component itself, the geometric structure of the component, the refractive index difference of the component and the packaging component, and the scattering characteristics of the component structure. Among them, internal quantum power is the product of the component's extraction force, that is, the overall part of the component, that is, the external quantum power of the component. In the early period of component development, improve the internal quantum power. The first method is to improve the quality of the barrier crystal and change the structure of the barrier, so that the power energy is not easy to transform into thermal energy, and then directly improves the luminous power of the deep ultraviolet LED lamp beads, and then then then Increased the theoretical internal quantum power of 70%, but so internal quantum power is almost close to the theoretical limit. In this case, the internal quantum power of the improvement component cannot increase the total light of the component, so the extraction of the improvement of the progressive component becomes the primary research topic. The main way now is: change the external shape of the grain——TIP structure, change the surface roughness. 3. Deep ultraviolet LED lamp bead electrical characteristics: current control device, the load characteristics are similar to the UI curve of the PN knot, the minimal changes of the inflow voltage will cause significant changes in the forward current (index level). Small, and reverse breakdown voltage. You should choose the method that is suitable for actual use. As the temperature increases, the forward voltage of the deep ultraviolet LED lamp beads decreases, and the temperature coefficient is negative. Dark ultraviolet LED lamp beads consume power and partially converted into light energy. This is exactly what we need. The remaining heat energy to increase the knot temperature. Can be represented by the calories (power) released. 4. The optical characteristics of deep ultraviolet LED lamp beads: Deep UV LED lamp beads provide a half -width monochrome. As the energy gap of semiconductors decreases as the temperature increases, the peak wavelength of its luminescence is with the temperature with the temperature with the temperature. Increasing the increase, that is, the spectrum is red, the temperature coefficient is2 3A/. Dark ultraviolet LED pearly brightness L changes with the positive current. Increasing the current, you can approximate the light brightness; the higher the ambient temperature, the lower the composite power, the lower the luminous intensity, and the lower the other luminous brightness. Deep ultraviolet LED lamp bead fever characteristics: small current, the temperature rise is not obvious. When the ambient temperature is high, the main wavelength of the deep ultraviolet luminous beads will redize, the brightness decreases, the light luminous uniformity decreases, and the consistency becomes poor. Special dot matrix and large screen temperature rise have a great impact on the reliability and stability of LED. So heat dissipation design is the key. Deep ultraviolet LED lamp bead life: Long -term work of deep ultraviolet LED lamp beads will lead to light aging, especially high -power deep ultraviolet LED lamp beads. When measuring the life of the deep ultraviolet LED lamp beads, it is not enough to use the damage of the bulb as the loss of the life of the deep ultraviolet LED beads. For example, 35%, this is more reasonable. High power Deep UV light emitting diode packaging: First of all, consider heat dissipation and out of light. In terms of heat dissipation, the copper -based radiator lining is used, and then connected to the aluminum radiator. The grain and the heat lining are welded. The heat dissipation method is better. In terms of light, choose the chip inverted skills, and add the reflex surface to reflect the light to spoil the light from the bottom and the side, so that you can get more out of light.

Author: Tianhui-Air Disinfection

Author: Tianhui-UV Led manufacturers

Author: Tianhui-UV water disinfection

Author: Tianhui-UV LED Solution

Author: Tianhui-UV Led diode

Author: Tianhui-UV Led diodes manufacturers

Author: Tianhui-UV Led module

Author: Tianhui-UV LED Printing System

Author: Tianhui-UV LED mosquito trap

GET IN TOUCH WITH Us

You can find us here