Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Method of Identifying the Quality of LED Module Light Source Lamp Band Quality

2023-01-08

Tianhui

101

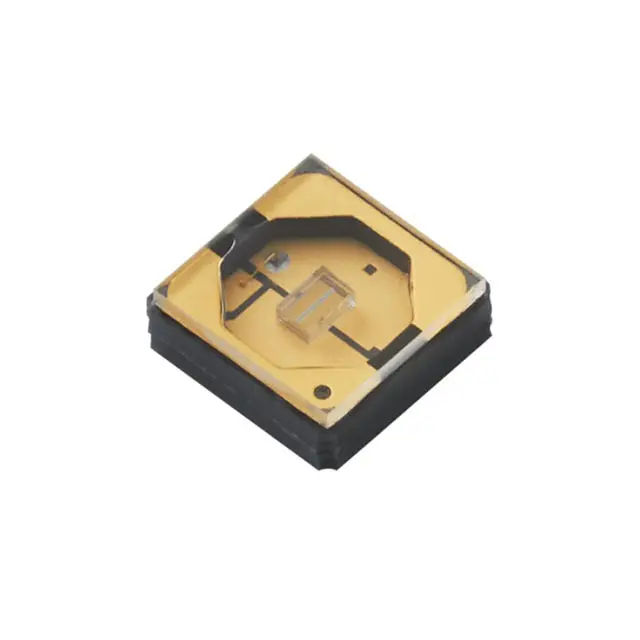

LED module light source lamp bands are low due to production entry, many people participate in this project. However, some experienced people have a way to recognize that the LED lamp belt produced by regular manufacturers and the cottage version of the LED light zone (referring to the product produced by the leased indoor manual work) can be seen from the appearance at a glance. Next, take the products we leave the Rainbow LED lamp belt as an example to explain the method of identifying the quality of the LED light belt with the eyes. 1. Look at the packaging. The regular LED module light source light band is used with anti -static effects, generally 5 meters 1 or 10 meters 1 volume. In order to save costs, the cottage version of the LED light zone uses the recycling volume. There is no static moisture -proof packing bag. If you observe the volume carefully, you can see the traces and traces when the label disappear. 2. Look at the label. There are print labels on the regular LED lamp belt packaging bag and roll plate, not a printing label. The label of the plagiarism version is printed, and the specifications and parameters are not uniform. 3. Please see the attachment. The formal LED module light source light band is added in the box and the lamp belt specification book, and the LED light belt equipment connector and Kato. There are no these attachments in the cottage LED lamp belt packaging box. Because they can save. 4. Look at the welding point. The LED lamp belt produced by the regular LED light belt uses the SMT patch process, and the production of tinnum paste and reflux welding process. Therefore, the solder joints on the LED light band are relatively smooth and the amount of solder is not large. The solder joints extend from the FPC pad to the LED electrode. The welding tin volume of the welding point of the plagiarism version of the LED light zone is uneven, and the welding foot is wrapped in one more dot. At the same time, the tin head of different degrees is a typical phenomenon of hand -welded welding. 5. Look at the quality FPC. The FPC is divided into two types: copper and pressure -extended copper. The copper foil of copper plate is prominent. Take a closer look at the connection of the FPC. On the other hand, the crushing copper is closely connected to the FPC, and the phenomenon of the pad will not produce. You can bend arbitrarily. If the copper plate is curved too much, the pad will fall off. The temperature is too high during repair, and the pad will fall off. 6. LED module light source lamp band observation surface cleanliness. If the SMT is made through the LED light belt, the surface of the surface is very good, and no impurities and dirt can be seen. However, the cottage version of the LED lamp band produced by hand -welded, no matter how clean the surface is, will leave stains and cleaning marks. At the same time.

Author: Tianhui-Air Disinfection

Author: Tianhui-UV Led manufacturers

Author: Tianhui-UV water disinfection

Author: Tianhui-UV LED Solution

Author: Tianhui-UV Led diode

Author: Tianhui-UV Led diodes manufacturers

Author: Tianhui-UV Led module

Author: Tianhui-UV LED Printing System

Author: Tianhui-UV LED mosquito trap

GET IN TOUCH WITH Us

recommended articles

UV LED diodes have become prevalent in an assortment of applications, including disinfection, industrial curing, and specialization light. Their value arises from their capacity to deliver accurate and efficient UV light tailored to individual requirements. Classical mercury lamps, which have been performing comparable roles, are steadily being replaced with UV LED diodes since of their greater performance and eco-friendliness. This article explains why UV LED diodes are an excellent choice for current applications.

The sole UV light source that could start the UV curing process forty years ago was mercury-based arc lamps. Even though Excimer lamps and microwave sources have been invented, the technology has not changed. Like a diode, an ultraviolet light-emitting diode (LED) creates a p-n junction using p- and n-type impurities. Charge carriers are blocked by a junction boundary depletion zone.

no data

Contact Us

You can find us here

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service

We use cookies to ensure that we give you the best experience on and off our website. please review our privacy policy

Reject

Cookie Settings

Agree Now

Your basic information, online operation behaviors, transaction information, access data are necessary to offer you our normal purchase, transaction, and delivery services. Withdrawal of this authorization will result in the failure of shopping or even paralysis of your account.

Your basic information, online operation behaviors, transaction information, access data are of great significance to improve website construction and enhance your purchase experience.

Your basic information, online operation behaviors, transaction information, preference data, interaction data, forecasting data, and access data will be used for advertising purposes by recommending products more suitable for you.

These cookies tell us how you use the site and help us to make it better. For example, these cookies allow us to count the number of visitors to our website and know how visitors move around when using it. This helps us to improve how our site works. For example, by ensuring that users find what they are looking for and that the loading time of each page is not too long.