Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

LED Lamp Bead Production Worker Monochrome LED Lamp Bead Art

2023-01-20

Tianhui

38

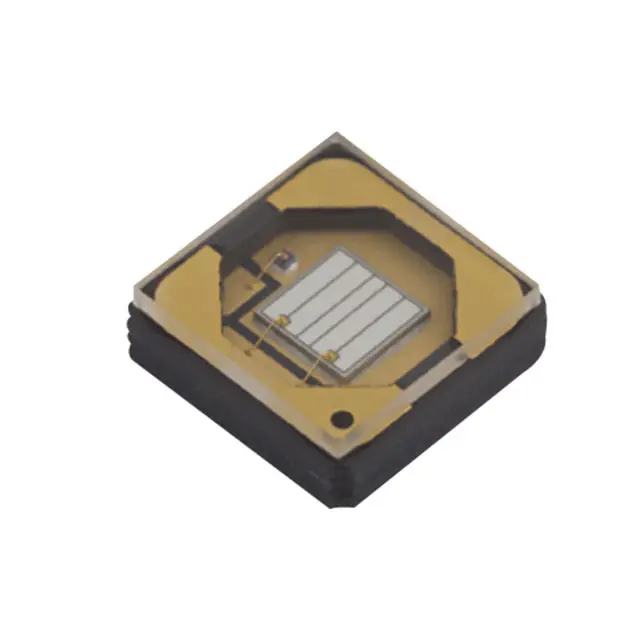

Important production process of LED lamp beads: raw material: LED bracket, LED chip, LED solid crystal glue, gold wire, LED packaging glue, LED fluorescent powder, etc. LED lamp beads production equipment: automatic crystal machine, plasma washing machine, automatic welding machine, automatic point -liquid machine, glue mixer, oven, splitter, automatic sorting machine, automatic packaging machine, automatic packaging machine. Production environment: LED lamp beads need to perform excellent electrostatic protection throughout the process, because LED chips are afraid of static breakdown. Important production steps: 1. LED bracket inspection. Important inspection project: appearance size, electroplating thickness, whether the oxidation phenomenon LED lamp bead isolation paper. 2. LED bracket baking. Use the device to bake the LED lamp bead bracket. It is important to remove the water vapor remaining during the injection process during the injection process. 3. LED bracket plasma wash. Purmake washing is important to form an arc inside the equipment by hydrogen and oxygen, remove the organic matter residual of the LED bracket appearance, and improve the bonding force of solid crystals. 4, solid crystals. Put the LED chip with LED solid crystal adhesive on the LED bracket with the automatic solid crystal machine. 5. Baking. Bake the solid crystal glue and let the LED chip and LED bracket form a fine bonding. After the baking is finished, the solid crystal thrust test should be performed. 6. Golden line overlap. Weld the pads on the LED chip and the conductive area on the LED bracket with gold wire for welding. Several types of welding: golden silk spherical welding, wedge -shaped welding. The metal wires used are: gold, aluminum lines, alloy lines, copper wires, etc., LED lamp beads are important to use gold, alloy lines, and copper wires. After the welding is completed, the welding point must be measured and welded. 7. Sealing. LED packaging glue formed in the cup -shaped area formed by the LED bracket is filled. If it is made of white LED lamp beads, the appropriate amount of fluorescent powder needs to be added to the packaging glue. This step is the step to produce white light, but also the steps that determine the color temperature, showing fingers, and various colors. Companies that produce white light beads will have a special person with fluorescent powder. 8. Baking. Clean the LED packaging glue through the oven for. 9. The LED bracket cuts from many sections connected to the way, cut into an independent small unit for LED lamp beads. 10. Sort. Each cut small lamp bead is set for various parameters: voltage, color temperature, light flux, etc. 11. Packing. Packaging the lamp beads with no different parameters. --- The article comes from LED lamp beads, please indicate Tongjia (China) www.tongjialed.com

Author: Tianhui-Air Disinfection

Author: Tianhui-UV Led manufacturers

Author: Tianhui-UV water disinfection

Author: Tianhui-UV LED Solution

Author: Tianhui-UV Led diode

Author: Tianhui-UV Led diodes manufacturers

Author: Tianhui-UV Led module

Author: Tianhui-UV LED Printing System

Author: Tianhui-UV LED mosquito trap

GET IN TOUCH WITH Us

recommended articles

The UV light utilized nowadays is traditionally produced by UV lamps based on mercury vapor for numerous industrial and medicinal uses. It has long been established that certain UV light waves have a severe germicidal effect, causing irreparable damage to DNA and RNA in microorganisms like viruses, bacteria, and fungi.

no data

Contact Us

You can find us here

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service

We use cookies to ensure that we give you the best experience on and off our website. please review our privacy policy

Reject

Cookie Settings

Agree Now

Your basic information, online operation behaviors, transaction information, access data are necessary to offer you our normal purchase, transaction, and delivery services. Withdrawal of this authorization will result in the failure of shopping or even paralysis of your account.

Your basic information, online operation behaviors, transaction information, access data are of great significance to improve website construction and enhance your purchase experience.

Your basic information, online operation behaviors, transaction information, preference data, interaction data, forecasting data, and access data will be used for advertising purposes by recommending products more suitable for you.

These cookies tell us how you use the site and help us to make it better. For example, these cookies allow us to count the number of visitors to our website and know how visitors move around when using it. This helps us to improve how our site works. For example, by ensuring that users find what they are looking for and that the loading time of each page is not too long.