Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

LED Data Measurement Method Daquan

2022-10-14

Tianhui

107

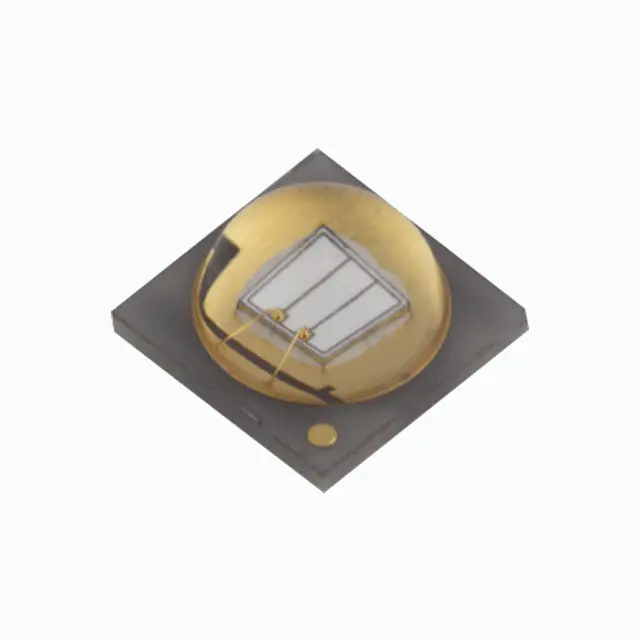

1. Media: Lighting diode (LED) as a emerging emitting body, with high electro -optic effect, small volume, long life, low voltage, energy saving and environmental protection, etc., is the first choice device for new generation of lighting. The growth of LEDs has been accepted by the national table, and new products and new crafts are stacked. In recent years, LED property has grown agile, the light efficiency has continued to increase, and the brightness has continued to increase. Now, LEDs have obtained the use of year -on -year use, especially the inexhaustible forward of white light LED technology, making it gradually popularize in the field of lighting. The growth of LED property is shown in Figure 1. 2. LED work principle: Lighting diode (LED) is a solid device that can convert electrical energy into optical energy. Its layout is mainly composed of PN chips, electrodes and optics systems such as PN chips, electrodes, and optics systems. The foundation of LED's foundation is a process of electro -light conversion. When a positive bias pressure is applied to the two ends of the PN knot, because the PN tenth of the power is decreased, the positive charge of the P area will be distinguished to N. Differential scattered, at the same time, constitute a pile of non -balanced charge in two areas. Because the small carrier injection occurs in the current is relatively endless, the non -balanced empty acupoint injected into the price zone should be compounded with the electron in the guide zone. Radiation, the worse the energy of the electronics and the cave, the higher the photon energy that occurs, the higher the energy that occurs. The energyweight is different, the frequency and wavelength of light are different, and the color of the response light will be different. LED work principle is shown in Figure 2. LED lamp bead model price 3, LED's light parameters 3.1 Light flux: light flux is the amount of light emitted during the light source, that is, radiation power (or radiation flux) can be infected by the human eye vision system. The symbol of the optical flux isφThe unit is lingering (LM). Following spectral radiation fluxφ((λ), From the following formula, the amount of light flux:φ= Km φ((λ) GV (GV (λ)ofλIn the formula, V (λCure—Relatively spectral light vision; km—The most night value of radiation spectral light vision, the unit is LM/W. In 1977, the KM value was affirmed by the International Metrology Commission of 683LM/W (λM = 555nm). 3.2 Light intensity: The luminous intensity of the light source on the given target I is the optical flux D.φExcept for this three -dimensional corner DωThe business, that is,: I = The unit of light emitting intensity is Kandera (CD), 1cd = 1LM/1SR. The sum of the light of the purpose of the space of the space is the flux of light. 3.3 Brightness: The brightness L at a certain point on the Overview of the Light Source is the luminous intensity of the DS DS on the given target. Business, that is,: L = The unit is Cantra per square meter (CD/M2). When the outline of the light emitting is vertical with the purpose of the measurement, then COSθ= 1. 3.4 Lightness: The illuminance E of the Overview is the optical flux of the incident on the point of the dot.φIn addition. That is: E = Unit is Lx (LX), 1LX = 1LM/M2. 3.5 Other parameters: LED's light parameters are also encompassing: spectrals, color coordinates, main wavelengths and color purity, color heating and related color temperature, color rendering, color rendering index, etc. 4. LED light -color measurement needs 4.1 Avoid risk: LED is different from traditional lighting, it has the characteristics of a little light source, high brightness, narrow light beam output and other characteristics. When the LED is used in the underworld, if the light corner is not strictly controlled, a strong glare will occur. Some high -brightness LED products will even cause the risk of light radiation to the human body. Light color measurement can be used for the safe utilization of LED. 4.2 Promoting the growth of LED property: The light color measurement of LED can provide attempts that can provide the annual amount, which can be used as the scale of the appraisal LED product and whether it is or not. 5. The light color measurement method of LED 5.1 Measurement of the Light Flike 5.1.1 Points method: Test the strong light of the LED on each target, and then calculate these light value Cure. 5.1.2 Points Ball method: Point balls, also known as Lighting Ball, are a hollow full global shell. Apply white reflective layer in the inner wall, and the inner wall of the ball is shot on average. The light source that occurs on the ball wall is superimposed from the light degree that occurs repeatedly reflected light. It can be seen from the principle of integral science. The lightness on the sphere is proportional to the light source of light source light. Show. However, due to the differences of the physical layout and nature of the scale light (such as receiving), the test results are required when manipulating the volume of the volume. 5.1.3 2πTest of three -dimensional corner light flux: There is also a test layout (as shown in Figure 5) when manipulating the volume of the volume of the volume ball, which is called the test of the front light flux or 2πStereo corner light flux. This test is actually not the total light flux of the LED, but people often mix it with the total light flux of the test LED. 5.2 Light intensity measurement: For the test of LED light, CIE-127 sets two test premises, as shown in Figure 6 and table. 5.3 Brightness: The test of LED brightness is used in the process of testing the brightness of the LED chip and evaluating the safety of LED light radiation. The test generally adopts the imaging method. The test of the chip can be measured by micro -imaging, as shown in Figure 7. 5.4 Light degree measurement: Strictly speaking, the light degree cannot be regarded as the optical parameters of LED. Because the lighting of real places in general environment is completed by multiple LEDs. 5.5 Measurement of other parameters: other parameters such as color coordinates, main wavelengths and color purity, color heating and related color temperature, color rendering, and color rendering index can be manipulated. 6. LED's light radiation safety test and evaluation: In recent years, the LED's light radiation is more and more concerned. Zhejiang New Year's Eve Three -color Instrument Co., Ltd. started the research of light radiation testing in China in China. In the middle of the national electrical source detection. At present, the three colors of Zhejiang have made new progress in the light radiation test of LEDs. Lighting LED testing for PHILIPS has been conducted, and the LED radiation safety testing system with China's independence property rights has been studied. The process of introducing LED light radiation safety testing and evaluation is introduced below. 6.1 Tested white light LED 6.1.1 LED Premise: Light -tube current 0.417A, voltage 12V DC, power 5W. 6.1.2 The texture of the object and the spectrum (as shown in Figure 8) 6.2 Test of the indecent light source of the table: As shown in Figure 9, our manipulation of the index light source test system was tested by the white light LED. 0°(Positive) and 90°The purpose of the target is 10°The image obtained from the shooting is not an elegant light source. In theory, we should conduct light and peaceful tests at the purpose of each target, but for simplicity, this article is only 0 to 0 to 0°The environment of the target purpose is to test and evaluate (because the target target has the strongest output), other angles can be pushed. 0°The target table of the target is not elegant light. 6.3 Test premise 1: In accordance. The white light LED hole is 2m from the light collar, and the diameter of the light collar is 50mm in diameter. Test results explanation: Category 1 AEL calculates 400 to 600nm optical chemical risks: the thermal risk of not delineating AEL400 to 700nm: Ael that does not delineate AEL700 to 1400nm: Unable to delineate AEL conclusion: The white light LED is 1 test premise 1 1 The measured light radiation output of the lower -testing of the AEL delineation that does not span 1 type of laser products. 6.4 Test prerequisite 2 White light LED light -out hole is 100m from the light collar, and the diameter of the light collar is 7mm. Explanation of test results: (1) Category 1 AEL calculates 400 to 600nm optical chemical risks AEL: Disable AEL conclusion: The white light LED span 1 type of laser product photochemical risk AEL delineation, does not belong to type 1 products 1 product. (2) Category 2 AEL's calculation of 400 to 700nm AEL: Ael, which does not delineate AEL700 to 1400nm: No leap -off AEL conclusion: The white light LED test the test premise 2 Test the 2 types of laser products AEL delineation delineates. 6.5 Prerequisites for radiation degree or radiation test: The test layout of the test premise in the test process 2 and the test premise of radiation or radiation testing is not different. The white light LED light radiation output span 1m of AEL. 6.6 Conclusion: Based on the above explanation, it can be known that the test white LED product is a type 2 LED product. However, in the general environment, because people's eyes have a blink of an eye, natural evasion reflections, so that they will not cause danger to people's eyes. According to the above introduction, it can be seen that the test and evaluation of LED light radiation is a very complicated process. Touching many aspects. However, the test and evaluation of LED light radiation peacefulness has gradually become a rare content in the test of LED products. For example, all LED products sold in Europe must be in accordance with EN-60825 (equal to IEC-60825) scale. Inspection. Therefore, we should put on the research investment in the category of the year. 7. LED light -color measurement and lighting evaluation: The ultimate goal of LED lighting is to get the best lighting results, and the black and white of determining the results of the lighting depends on the light color measurement of LED. 7.1 Evaluation of lighting at this moment: The current lighting evaluation is mainly based on several primary optical foundation: light flux, brightness, light intensity, and light degree. Evaluation of light source light radiation sensor surface. These optical foundations are obtained according to the biophysical characteristics of the human eye, and they are also a spectral light vision function V (CIE) recognized by an International Lighting Commission (CIE)λ) The results of the corresponding radiation hugs are enough to know the relationship: light arms (λ) = Kmgv (λ) Radiation embrace (λ) In the formula, km—683lm/w. 7.2 Existing problems and deficiencies: The biological physical mechanism of human eyes is very complicated, and the response to light stimulation in the different environment is also different. The central vision is particularly complicated. It is based on the above spectral light vision effect. As shown in Figure 10, the stimulus value of a uniform light source to the eyes of people's eyes is different from the visual and dark vision. In addition, the current domestic lighting evaluation lacks consideration of the safety of optical creatures, which may cause the risk of differences in the human body. 7.3 Solution 7.3.1 Test method and instrument: Take a full spectral method to measure the spectral distribution of LEDs, and then manipulate the spectrometer for dating test. 7.3.2 Evaluation method (1) Lighting results: According to the visual premise of divergent visual premise, a different spectrum light vision function is weighted by the LED spectrum distribution data, and the actual lighting result of the measurement of the metering source is radiated under the corresponding visual premise. For example, the dark vision spectrum light vision function is adopted during the secret vision. When the visual vision is visually visual, the visual spectrum light vision function is adopted. (2) Light -biological safety: According to the type of risk, the corresponding result function function weighted LED spectrum distribution data to obtain real risk results. In short, LED lighting evaluation should be suitable. 8. Summary and Zhanwang (1) The growth of LED property is inseparable from the LED light -color measurement technology. In order to conform to the lighting of LED, the future light -color measurement technology should be broken. (2) LED lighting and light color measurement shall be rewarded, and everything is guided by the actual requirements of human beings. (3) Current mission: Enhance the research of the fundamental theory of biology related to the human body, and enhance cross -cooperation of disciplines; In connection with international standards, accelerate the formulation and implementation of normative documents, try their best to intervene in international renowned internationally renowned internationally renowned well -known internationally renowned internationally renowned internationally renowned Organization; Grand research investment in the New Year's Eve, and research and development of light -colored measuring instruments with independent common sense property;.

Author: Tianhui-Air Disinfection

Author: Tianhui-UV Led manufacturers

Author: Tianhui-UV water disinfection

Author: Tianhui-UV LED Solution

Author: Tianhui-UV Led diode

Author: Tianhui-UV Led diodes manufacturers

Author: Tianhui-UV Led module

Author: Tianhui-UV LED Printing System

Author: Tianhui-UV LED mosquito trap

GET IN TOUCH WITH Us

You can find us here