Warning Instructions For Use

Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Tianhui Led 400nm Tianhui Led 400nmmade in China

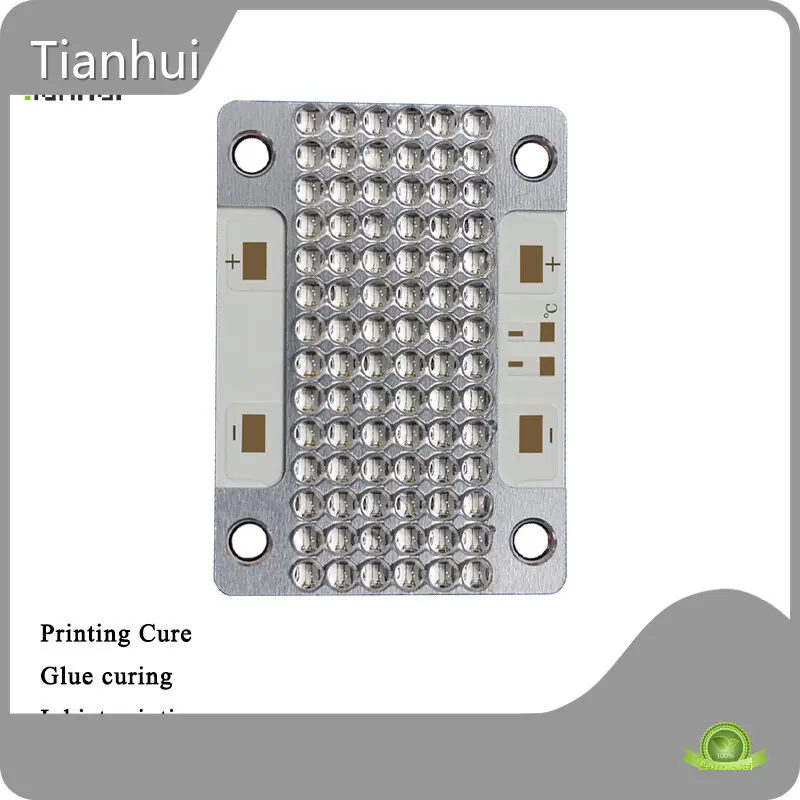

High Power 200-300W UVA LED COB/Module Series For Printing Cure Glue Curing Inkjet Printing

| PEAKWAVELENGTH | POWER | FORWARDVOLTAGE | FORWARDCURRENT | RADIANTFLUX | RADIATIONANGLE |

| 365nm | 150~250W | 48~54V | 4~5A | 12~15W/cm^2 | 30/60 |

| 385nm | 200~300W | 46~52V | 4~6A | 15~18W/cm^2 | 30/60 |

| 395nm | 200~300W | 46~52V | 4~6A | 15~18W/cm^2 | 30/60 |

| 405nm | 200~300W | 46~52V | 4~6A | 15~18W/cm^2 | 30/60 |

| APPLICATIONS |

Printing Cure Glue Curing Inkjet Printing

|

||||

UVA Curing Process

The UV wavelength used in industry ranges from 340nm to 420nm for its application. The process of using UV irradiation to harden materials is called UVCuring Process.

The more commonly used is the UVA band. Choosing the corresponding UV curing machine light for the corresponding adhesive band is an important process for improving curing efficiency. In addition, to improve curing efficiency, factors such as light intensity, temperature, power, and irradiation time of the UV curing machine need to be considered. Choosing appropriate parameters is a necessary condition for curing.

The conveyor belt system is equipped with a quiet variable speed motor, and the speed adjustment driver of the UV machine maintains a uniform and consistent speed of the conveyor belt under different loads. The UV equipment is equipped with a high intensity light, and the lightbox system can be removed and fixed to other assembly lines for use, increasing the flexibility of the equipment. The height of the conveyor belt to the light bulb can be adjusted, suitable for curing components of different sizes.

As a new curing scheme, its advantage is short curing time, which can significantly improve production efficiency. Compared to traditional oven curing, it also has environmental characteristics. Traditional oven curing produces a large amount of formaldehyde, and the toxic gases emitted can be harmful to human health. The UV curing machine, on the other hand, does not produce any toxic substances and is an ideal adhesive curing solution. However, direct exposure to ultraviolet radiation can harm human health, so protective measures should be taken in production or daily applications to avoid the harm caused by direct exposure to the human body.

Type of UV curing machine: Different sizes of cured items require different sizes of curing machines. There are portable styles, desktop box styles, hanging styles for industrial production, and large curing machines for large items. If you need to solidify small items such as electronic circuit boards, you can choose portable or desktop box type. If the curing application is printing or wood surface coating, a large high-power UV curing machine is required, as it is not suitable for ordinary small curing machines due to its requirements for speed, curing area, and machine power. There is also a desktop conveyor belt UV curing device. Designed for mass production or laboratory use.

Zhuhai Tianhui Electronic Co., Ltd. was founded in 2002 . This is a production oriented and high technology company integrated research and development, production, sales and solution providing of UV LEDs, which is specialized in doing UV LED packaging and providing UV LED solutions of finished products for various UV LED applications.

Tianhui electric has been engaging in UV LED package with full production series and stable quality and reliability as well as competitive prices. The products include UVA, UVB, UVC from short wavelength to long wavelength and complete UV LED specifications from small power to high power.

Safety Precautions

The UV LED COB module emits a strong UV light in the UVA range. It is strongly recommended to use the appropriate eye and body protection while using the product and to follow the recommended safety and handling precautions.

·Do not look directly into the UV module when it is operating.

·Always wear a UV-proof face shield and cover all exposed skin while the UV module is in operation.

·Hold the UV module so that the light beams are facing away from you.

·Always turn off the device and unplug the power cord before handling the module.

·Keep the module dry at all times.

·For indoor use only.

·Do not attempt to repair the product

1. To avoid energy decay, keep the front glass clean.

2. It is recommended not to have objects blocking the light before the module, which will affect the sterilization effect.

3. Please use the correct input voltage to drive this module, otherwise the module will be damaged.

4. The outlet hole of the module has been filled with glue, which can prevent water leakage, but it is not

recommended that the glue of the outlet hole of the module directly contact the drinking water.

5. Do not connect the positive and negative poles of the module reversely, otherwise the module may be damaged

6. Human safety

Exposure to ultraviolet light can cause damage to human eyes. Don't look at ultraviolet light directly or indirectly.

If exposure to ultraviolet rays is unavoidable, appropriate protective devices such as goggles and clothing should be

used to protect the body. Attach the following warning labels to products / systems

Company Advantages

· The design concept of led 400nm have a broad development prospect.

· The product is guaranteed by our professional and responsible QC team to meet the industry standards.

· Manufactured using premium-grade raw material, this product has found its application in varied fields.

Company Features

· Largely focused on led 400nm, Zhuhai Tianhui Electronic Co., Ltd. has made amazing progress over the years.

· We are granted a production certificate. This certificate is issued by the China Administration for Industry and Commerce. It can safeguard customers' rights and interests to the most utmost extent.

· Tianhui will provide clients with the most invaluable service all of the way. Get quote!

Application of the Product

The led 400nm of Tianhui can be used in many industries.

With a focus on customers, Tianhui analyzes problems from the perspective of customers and provides comprehensive, professional and excellent solutions.