Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

What Are the Requirements for Light Emitting Diode Welding

2022-12-21

Tianhui

53

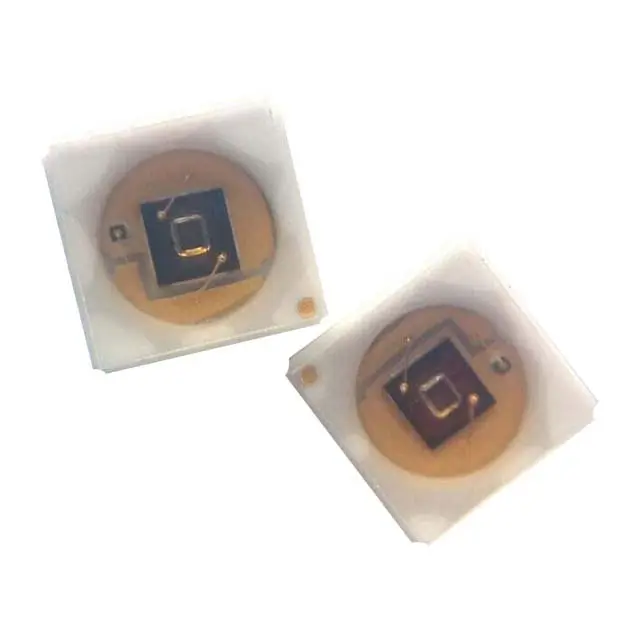

Some small knowledge introduction of light -emitting diodes. What are the requirements for welding of light -emitting diode? What problems need to be paid to when welding? What is the position of welding position?. Then the following is explaining these issues. What should I pay attention to when welding when weld in welding. 1. The LED emitting diode cannot be powered on during welding. 2. When using the soldering iron: the maximum power of the soldering iron is 30W, the highest temperature of the soldering iron tip: 280 C, the upper warming up to 60 seconds, and the maximum welding should not exceed 3 seconds; when using the soaking, the maximum temperature must not exceed 260 degrees, the most the most, the most at the most, the most at the most, the most at the most, the most at the most, the most at the most. It must not exceed 5 seconds for a long time. 3. Sipper welding position: greater than 3mm from the bottom surface of the colloid; soaked welding position: greater than 3mm from the bottom surface of the colloid. 4. When welding or heating, before the temperature returns to normal, you must avoid any vibration or exertion for the LED. How to use the current after welding? 1. The light -emitting diode should work under the same current conditions. Generally, the current of the LED is 15-18mA. The current is too large. 2. The normal working current of LAMP LAMP is 20mA, and the slight fluctuations of the voltage (such as 0.1V) will cause a large fluctuation of current (10%-15%). 3. Overcurrent protection: Excessive current will cause the burning and acceleration attenuation of LED light -emitting diodes and the brightness of brightness. When designing the circuit design, the different current resistance should be carried out according to the voltage of the LED light -emitting diodes to ensure the stable and best working state of the LED light -emitting diode. The welding process and current of the light -emitting diode are shared here. If you need to learn more, please consult this website hotline.

Author: Tianhui-Air Disinfection

Author: Tianhui-UV Led manufacturers

Author: Tianhui-UV water disinfection

Author: Tianhui-UV LED Solution

Author: Tianhui-UV Led diode

Author: Tianhui-UV Led diodes manufacturers

Author: Tianhui-UV Led module

Author: Tianhui-UV LED Printing System

Author: Tianhui-UV LED mosquito trap

GET IN TOUCH WITH Us

recommended articles

UltraViolet (UV) LED chips, created by expert manufacturers, hold big promise. In this detailed guide, the focus is on the intricacies of UV LED chips, their making, and how they are evolving. The spotlight is also on the impactful role of key manufacturers in advancing this cutting-edge technology.

In the food and beverage industry, ultraviolet (UV) disinfection technology is a rapidly expanding sector. UV radiation is used to disinfect water, air, and surfaces by killing bacteria, viruses, and other pathogens to make the food healthy. This technology has grown in popularity due to its efficiency, usability, and minimal cost.

Various water treatment technologies including UV water disinfection have been developed in response to the rising demand for pure drinking water. In recent years, Ultraviolet-C (UV-C) LED technology has garnered significant interest for its potential applications in potable water treatment. This technology has a number of advantages over conventional mercury-based UV lamps, including energy efficiency, lower operating costs, and a smaller environmental footprint.

Ultraviolet (UV) disinfection/water purification technology uses UV light to kill harmful microorganisms in water. It's a natural and effective way to purify water without adding chemicals, making it a popular choice for many households and industries. The process works by exposing water to a strong UV light source, which damages the DNA of bacteria, viruses, and other pathogens, causing them to die.

UVC LED technology has gained significant attention in recent years, and it's no surprise that the market is expanding with more home appliances and consumer products adopting the technology. The COVID-19 pandemic only fueled the demand for UVC LED products as consumers and businesses seeked effective ways to disinfect their environments. UVC LEDs offer a safe, reliable, and efficient way to kill bacteria and viruses, making them a popular choice for various applications.

no data

Contact Us

You can find us here

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service

We use cookies to ensure that we give you the best experience on and off our website. please review our privacy policy

Reject

Cookie Settings

Agree Now

Your basic information, online operation behaviors, transaction information, access data are necessary to offer you our normal purchase, transaction, and delivery services. Withdrawal of this authorization will result in the failure of shopping or even paralysis of your account.

Your basic information, online operation behaviors, transaction information, access data are of great significance to improve website construction and enhance your purchase experience.

Your basic information, online operation behaviors, transaction information, preference data, interaction data, forecasting data, and access data will be used for advertising purposes by recommending products more suitable for you.

These cookies tell us how you use the site and help us to make it better. For example, these cookies allow us to count the number of visitors to our website and know how visitors move around when using it. This helps us to improve how our site works. For example, by ensuring that users find what they are looking for and that the loading time of each page is not too long.