Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

UVLED Lamp Beads Curing Printed Printed Printed Raw Infrared LED Lamp Bead Manufacturers and Advantages

2023-01-11

Tianhui

61

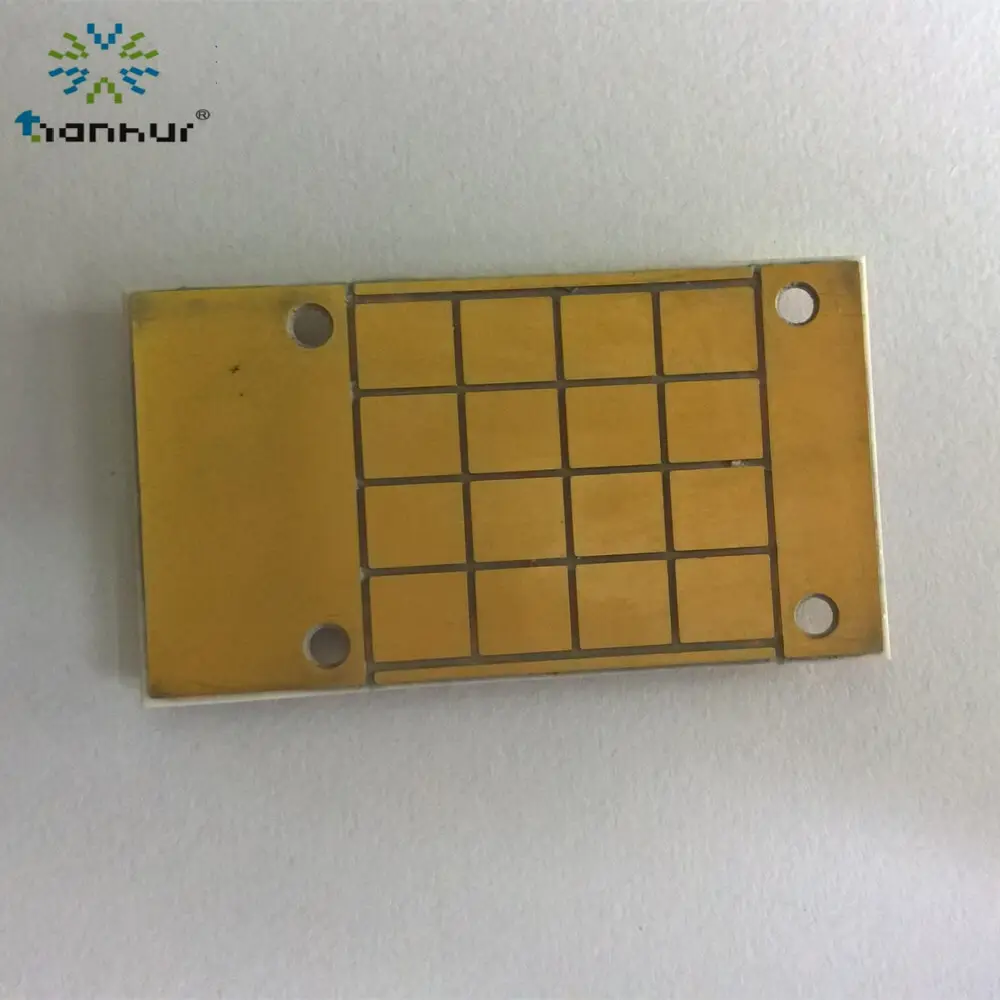

Through the growth of UVLED lamp beads in recent years, whether it is the old rubber print industry, the use of UVLED lamp beads is more and more used. Everyone knows that compared with the traditional solvent -type ink, UVLED curing ink has good gloss, strong three -dimensional sense, no harmful solvents volatilization and other strengths. It is extraordinary. CICS prevents errors such as long drying cycles of solvent -type inks and obtaining an area of land. UVLED optical curing ink is printed after printing. 1. UVLED lamp beads CICF: UVLED lamp beads solidify the principle of solidification: inserted light stimulus or light sensitrant in an extraordinary formula, and receive high -intensity ultraviolet light in UV (UV) light curing equipment in the end. Base, thereby stimulating polymerization, cross -linking, and branches, so that the resin converts the liquid state into a solid state within a few seconds. 2. UVLED lamp beads inkjet printing: The ultraviolet light sources that have been used in the printing industry have accepted light sources such as high -voltage mercury lamps and metal halogen lamps. Due to the year -long type of lamps and power assembly, users are worried about the power consumption of power consumption years. Night and fever caused problems such as the destruction of the printing machine and the destruction of the bearing objects and the occurrence of ozone in the use of printed objects. Following the advent of UVLED lamp beads light curing skills, due to its environmental characteristics, the pollution is small than the solvent type, and the operating cost is even lower than the solvent type. UVLED optical solidification skills are a new skill of the 10 brands of green industry LED lamp beads. It was once rated by the North American Radiation Consortium“5E”Features of industrial skills, which enrich the characteristics of this skill, is efficient, energy conservation, friendly, economical, and compliance. UV curing lights often used in the market today are generally mercury arc lamps, referred to as mercury lamps. The UV mercury lamp has a limited service life, and the energy consumption is not high than the use of coaxing. For the solvent -based ink, because there is no VOC emissions, it has the characteristics of environmental protection and friendly situation. However, there are some hidden pollution in UV mercury lamps. influences. In 2008, LED curing skills first expressed their statements at the Druba Exhibition, which aroused widespread concern in the industry. Many printing machines and ink manufacturers showed their own skills. UVLED solidification is the most attractive skill in the field of energy curing. This skill is based on its energy -saving, efficient, economical, environmentally friendly, and compliant UV high -quality and infrared radiation. The more it is favored by people. At present, the market's demand for LED UV skills is very strong. Digital printing has become the most year -old market for this skill. The inkjet category is at most, and the upperlight of UVLED lamp beads can just be satisfied with this category. need.

Author: Tianhui-Air Disinfection

Author: Tianhui-UV Led manufacturers

Author: Tianhui-UV water disinfection

Author: Tianhui-UV LED Solution

Author: Tianhui-UV Led diode

Author: Tianhui-UV Led diodes manufacturers

Author: Tianhui-UV Led module

Author: Tianhui-UV LED Printing System

Author: Tianhui-UV LED mosquito trap

GET IN TOUCH WITH Us

recommended articles

Are you looking for top-notch UV LED solutions? Look no further than our company, with an impressive 23 years of excellence in this field. We have been leading the way in providing high-quality UV LED solutions, setting the industry standard for nearly a quarter of a century. Trust us to deliver the best and most reliable products for all your UV LED needs.

Sunlight remains the most common source for achieving a tan, but its ultraviolet (UV) rays come with inherent risks. So is there any risk-free solution for this? Yes, and the answer is UV LED Lights. Let’s not waste a second and dive into the science behind UV light and tanning, explore traditional tanning methods, and introduce Tianhui UV LED, a leading supplier of UV LED solutions, as a potential alternative.

In the food and beverage industry, ultraviolet (UV) disinfection technology is a rapidly expanding sector. UV radiation is used to disinfect water, air, and surfaces by killing bacteria, viruses, and other pathogens to make the food healthy. This technology has grown in popularity due to its efficiency, usability, and minimal cost.

The rapid expansion of the electronics industry has necessitated the development of new and innovative technologies to propel the industry forward. The application of UV LED solutions is one of the emerging technologies in the electronics industry. Due to their unique characteristics, such as long lifespan, energy efficiency, and compact size, these solutions have been extensively adopted in the industry as a suitable alternative to conventional lighting sources.

UV LED curing is a technique that employs ultraviolet light to cure or harden substances. This procedure involves exposing the material to UV LED diodes emitting UV light. When UV light strikes a substance, it initiates a chemical reaction that causes the substance to harden or resolve. UV LED diodes emanate UV-A, UV-B, and UV-C light, which correspond to the wavelengths required to initiate the curing process.

As summer approaches, so does the pesky problem of mosquitoes. These tiny insects can ruin a peaceful outdoor evening, leaving us with itchy bites and disease risk. Fortunately, there's a solution in the form of UV LED mosquito traps. These devices use the power of ultraviolet light to attract mosquitoes and other flying insects better.

Are you aware of the latest findings on the transmission rate of the new coronavirus? A recent study has uncovered a shocking discovery- the air transmission rate of the virus may be a staggering 1,000 times that of the contact surface! This means the virus may spread faster and farther than we previously thought. Keep reading to learn more about this groundbreaking research and what it means for our fight against the pandemic.

Are you looking for a robust and flexible solution to disinfect your space? Look no further than mobile UV units. These innovative robots move from room to room, eliminating harmful germs and bacteria on surfaces. Mobile UV led diodes are becoming popular as more industries outside of healthcare catch on to the benefits of UV disinfection.

no data

Contact Us

You can find us here

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service

We use cookies to ensure that we give you the best experience on and off our website. please review our privacy policy

Reject

Cookie Settings

Agree Now

Your basic information, online operation behaviors, transaction information, access data are necessary to offer you our normal purchase, transaction, and delivery services. Withdrawal of this authorization will result in the failure of shopping or even paralysis of your account.

Your basic information, online operation behaviors, transaction information, access data are of great significance to improve website construction and enhance your purchase experience.

Your basic information, online operation behaviors, transaction information, preference data, interaction data, forecasting data, and access data will be used for advertising purposes by recommending products more suitable for you.

These cookies tell us how you use the site and help us to make it better. For example, these cookies allow us to count the number of visitors to our website and know how visitors move around when using it. This helps us to improve how our site works. For example, by ensuring that users find what they are looking for and that the loading time of each page is not too long.