Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Unveiling The Advantages Of UV Curing In Manufacturing

Welcome to our latest article, "Unveiling the Advantages of UV Curing in Manufacturing." In this piece, we will explore the numerous benefits of UV curing in the manufacturing industry and how it has revolutionized the production process. Whether you are already familiar with UV curing or are hearing about it for the first time, this article will provide valuable insights into its efficiency, cost-effectiveness, and environmental impact. Join us as we delve into the world of UV curing and discover how it can transform the way products are made.

Understanding the Process of UV Curing in Manufacturing

UV curing is a crucial process in manufacturing that offers a wide range of advantages for businesses in various industries. In this article, we will delve into the process of UV curing and how it contributes to enhancing the manufacturing process. As a leading manufacturer in the industry, Tianhui has recognized the significance of UV curing and has integrated this process into our manufacturing operations to deliver high-quality products to our customers.

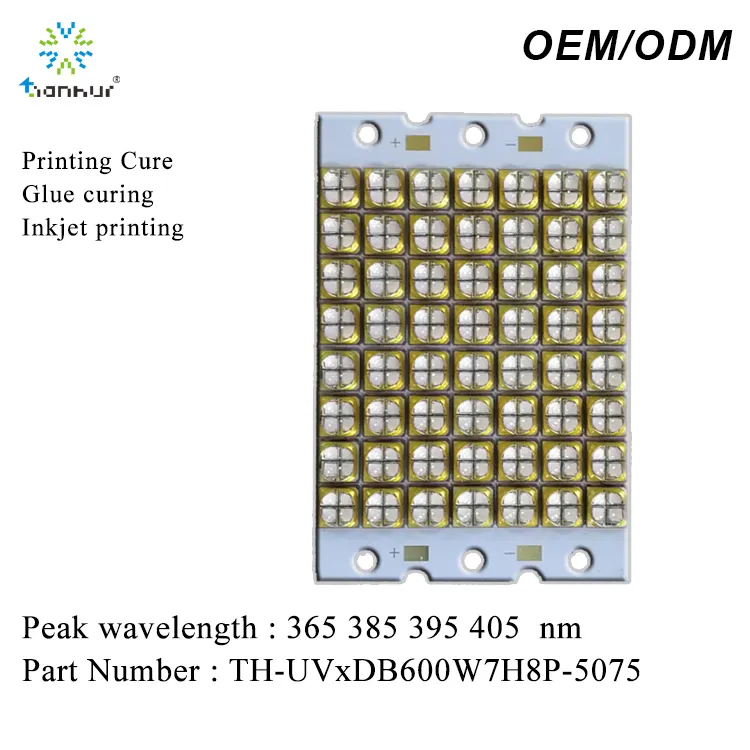

UV curing, also known as ultraviolet curing, is a photochemical process that uses ultraviolet light to instantly cure or dry inks, coatings, adhesives, and other materials. This process is widely used in the manufacturing of products such as automotive parts, electronics, medical devices, and packaging materials. The UV curing process involves the use of UV light, which activates photoinitiators in the material, causing polymerization and hardening. This results in a durable and high-quality finish that meets the stringent requirements of modern manufacturing.

One of the key advantages of UV curing in manufacturing is its rapid curing time. Unlike traditional curing methods that require heat or chemical reactions to dry or cure materials, UV curing is almost instantaneous. This allows for increased productivity and shorter processing times, ultimately leading to cost savings for manufacturers. At Tianhui, we have witnessed significant improvements in our manufacturing efficiency and turnaround times since incorporating UV curing into our processes.

In addition to its rapid curing time, UV curing also offers enhanced durability and performance. The materials cured using UV light exhibit superior resistance to abrasion, chemicals, and harsh environmental conditions. This makes them ideal for applications that require long-term reliability and performance, such as automotive coatings and electronic components. Tianhui has leveraged the benefits of UV curing to produce durable and high-performance products that exceed the expectations of our customers.

Furthermore, UV curing is a more environmentally friendly process compared to traditional curing methods. Since UV curing does not involve the use of solvents or produce volatile organic compounds (VOCs), it is considered a greener alternative for manufacturing. This aligns with Tianhui's commitment to sustainability and reducing our environmental footprint. By utilizing UV curing, we have minimized our emissions and waste, contributing to a cleaner and healthier manufacturing environment.

Another advantage of UV curing is its versatility in terms of the materials it can cure. Whether it's metal, plastic, glass, or composite materials, UV curing can effectively and efficiently cure a wide range of substrates. This flexibility has allowed Tianhui to diversify our product offerings and cater to the varying needs of our customers across different industries.

In conclusion, the process of UV curing plays a vital role in the modern manufacturing landscape. Its rapid curing time, enhanced durability, environmental friendliness, and material versatility make it a valuable asset for businesses seeking to improve their manufacturing processes. At Tianhui, we have harnessed the advantages of UV curing to elevate the quality and performance of our products, ultimately delivering value to our customers. As we continue to embrace innovation and excellence in manufacturing, UV curing will remain a cornerstone of our operations.

Key Benefits of Implementing UV Curing in the Production Process

In recent years, there has been a significant shift towards the implementation of UV curing in various manufacturing processes. This technology has revolutionized the production process in numerous industries, including automotive, electronics, packaging, and medical devices. With its numerous advantages, UV curing has become a preferred choice for many manufacturers looking to enhance efficiency and productivity while reducing costs.

Tianhui, a leading provider of UV curing equipment and solutions, has been at the forefront of this technology, helping businesses across different sectors to leverage the key benefits of UV curing in their production process. Through its innovative and reliable UV curing systems, Tianhui has enabled manufacturers to achieve faster curing times, improved product quality, and environmental sustainability.

One of the key benefits of implementing UV curing in the production process is its rapid curing capability. When compared to traditional methods such as heat or air drying, UV curing significantly reduces the curing time, resulting in faster production cycles and increased throughput. This not only translates to higher productivity but also allows manufacturers to meet tight deadlines and customer demands.

Additionally, UV curing offers superior quality and performance compared to other curing methods. The use of UV light to cure coatings, inks, and adhesives results in enhanced adhesion, durability, and scratch resistance. This ensures that the finished products meet the highest standards of quality, thereby enhancing the overall reputation and reliability of the manufacturer.

Moreover, UV curing is a sustainable and environmentally friendly option for manufacturers. Unlike solvent-based curing processes, UV curing does not emit volatile organic compounds (VOCs) or produce harmful by-products, making it a greener alternative. As a result, manufacturers can reduce their environmental footprint and comply with stringent regulations while maintaining a safe working environment for their employees.

Another significant advantage of UV curing is its ability to enable the use of a wide range of substrates. Whether it is plastic, metal, glass, or paper, UV curing can effectively cure various materials, expanding the possibilities for manufacturers and allowing for greater flexibility in product design and innovation.

Furthermore, the cost-efficiency of UV curing cannot be overstated. With reduced energy consumption, lower waste generation, and increased production speed, manufacturers can achieve significant cost savings over time. This makes UV curing a viable investment for companies looking to improve their bottom line and remain competitive in the market.

In conclusion, the implementation of UV curing in the production process offers a multitude of advantages that can drive efficiency, quality, sustainability, and cost-effectiveness for manufacturers. Tianhui is committed to providing cutting-edge UV curing solutions that empower businesses to harness these benefits and stay ahead in today’s fast-paced manufacturing landscape. As the adoption of UV curing continues to grow, it is clear that this technology will play a pivotal role in shaping the future of manufacturing across various industries.

The Environmental and Economic Advantages of UV Curing Technology

UV curing technology has gradually gained recognition in the manufacturing industry for its environmental and economic advantages. This article will explore the benefits of UV curing technology in manufacturing and how it can revolutionize the production processes. As a leading provider of UV curing solutions, Tianhui is at the forefront of driving innovation and sustainability in manufacturing.

One of the primary advantages of UV curing technology is its environmental impact. Traditional curing methods often involve the use of solvents and other chemicals that emit volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and posing health risks for workers. In contrast, UV curing does not produce VOCs, making it a more environmentally friendly option. As the world becomes increasingly focused on sustainable practices, UV curing technology offers a compelling solution for manufacturers looking to minimize their environmental footprint.

In addition to its environmental benefits, UV curing technology also offers substantial economic advantages for manufacturers. The curing process is significantly faster compared to traditional methods, leading to increased production efficiency and reduced energy consumption. This not only translates to cost savings but also allows manufacturers to meet demanding production timelines and improve overall operational efficiency. As a result, UV curing technology has the potential to revolutionize manufacturing processes, enabling businesses to stay competitive in today's rapidly evolving market landscape.

Moreover, UV curing technology is associated with improved product quality and durability. The precise control and instant curing capabilities of UV light ensure uniform and consistent results, leading to higher product reliability and performance. This is particularly beneficial for industries such as automotive, electronics, and medical devices, where product quality and longevity are of utmost importance. By adopting UV curing technology, manufacturers can enhance the quality of their products and gain a competitive edge in the market.

As a leading provider of UV curing solutions, Tianhui is committed to helping manufacturers harness the full potential of this innovative technology. Our advanced UV curing systems are designed to meet the diverse needs of different industries, offering unparalleled performance and reliability. With a focus on sustainability and efficiency, Tianhui's UV curing solutions enable manufacturers to achieve significant cost savings while minimizing their environmental impact.

In conclusion, the environmental and economic advantages of UV curing technology are clear, making it a compelling choice for manufacturers looking to improve their production processes. With its minimal environmental footprint, faster curing times, and superior product quality, UV curing technology has the potential to transform the manufacturing industry. As a leading provider of UV curing solutions, Tianhui is dedicated to delivering innovative and sustainable solutions that empower manufacturers to thrive in today's competitive market environment.

Ways to Optimize UV Curing for Different Manufacturing Applications

As manufacturing processes continue to evolve, it is essential for businesses to stay ahead of the curve and adopt innovative technologies to improve efficiency and productivity. One such technology that has gained significant traction in recent years is UV curing. UV curing refers to the process of using ultraviolet light to instantly cure or dry coatings, inks, adhesives, and other materials during the manufacturing process.

At Tianhui, we understand the importance of optimizing UV curing for different manufacturing applications, and we are committed to helping businesses harness the full potential of this technology. In this article, we will delve into the advantages of UV curing in manufacturing and explore various ways to optimize its use for different applications.

UV curing offers several advantages over traditional curing methods. One of the key benefits is its rapid curing time, which allows for faster production cycles and increased throughput. Additionally, UV-cured materials are more durable and resistant to wear and tear, making them ideal for a wide range of manufacturing applications. Furthermore, UV curing is a more environmentally friendly option, as it does not emit harmful volatile organic compounds (VOCs) into the atmosphere.

When it comes to optimizing UV curing for different manufacturing applications, it is crucial to consider the specific requirements of each application. For instance, in the automotive industry, UV-curable coatings are used to enhance the durability and aesthetics of automotive components. By fine-tuning the UV curing process, manufacturers can ensure that the coatings adhere effectively to the components, resulting in a flawless finish.

In the electronics industry, UV curing is used to bond and encapsulate delicate electronic components. By optimizing the UV curing process, manufacturers can achieve precise positioning and complete encapsulation of components, ensuring the reliability and longevity of electronic devices.

In the packaging industry, UV-curable inks and adhesives are used to enhance the visual appeal and durability of packaging materials. By optimizing the UV curing process, manufacturers can achieve consistent and uniform curing of inks and adhesives, leading to high-quality, eye-catching packaging solutions.

At Tianhui, we offer a range of UV curing solutions to cater to the diverse needs of different manufacturing applications. Our state-of-the-art UV curing systems are designed to deliver precise control over the curing process, ensuring optimal results for our customers. Whether it's automotive, electronics, packaging, or any other industry, our UV curing systems are engineered to meet the unique requirements of each application.

In conclusion, UV curing offers a multitude of advantages for various manufacturing applications, and optimizing its use can lead to significant improvements in efficiency, productivity, and product quality. At Tianhui, we are dedicated to supporting businesses in harnessing the full potential of UV curing through our advanced UV curing systems. With our expertise and cutting-edge technology, we aim to empower manufacturers to elevate their production processes and achieve remarkable results.

Future Prospects and Innovations in UV Curing for Manufacturing Industries

In today’s rapidly evolving manufacturing industries, the use of UV curing technology has revolutionized the way products are produced. From automotive and electronics to medical devices and consumer goods, UV curing has become an indispensable part of the manufacturing process. As we look towards the future, the prospects and innovations in UV curing hold great promise for even greater advancements in manufacturing.

At the forefront of this technological revolution is Tianhui, a leading provider of UV curing solutions. With a focus on innovation and quality, Tianhui has been instrumental in driving the adoption and advancements of UV curing technology in various industries. As we delve into the future prospects and innovations in UV curing for manufacturing industries, it is essential to understand the advantages that this technology offers.

UV curing, short for ultraviolet curing, is a photochemical process that uses ultraviolet light to instantly cure or dry inks, coatings, adhesives, and other materials. This process offers numerous advantages over traditional curing methods, such as thermal or chemical curing. Firstly, UV curing is incredibly fast, significantly reducing production times and increasing overall efficiency. Additionally, UV curing is a low-temperature process, which minimizes heat exposure and potential damage to sensitive substrates.

Furthermore, the use of UV curing leads to improved quality and consistency in the final product. The instant curing process ensures that the materials are fully cured, resulting in a durable and high-quality finish. This is especially beneficial in industries such as automotive and electronics, where precision and reliability are paramount.

Looking ahead, the future prospects of UV curing in manufacturing are incredibly promising. One of the key areas of innovation is the development of new UV-curable materials. Tianhui, in collaboration with industry partners, is continuously researching and developing new formulations for UV-curable inks, coatings, and adhesives. These advancements will open up new possibilities and applications for UV curing in various industries, further enhancing its versatility and effectiveness.

In addition to new materials, advancements in UV curing technology itself are driving innovation in manufacturing. Tianhui is at the forefront of developing more efficient and high-performance UV curing systems. These systems are designed to deliver precise and consistent UV doses, ensuring optimal curing while maximizing energy efficiency. This not only reduces operational costs but also contributes to a more sustainable and environmentally friendly manufacturing process.

Another aspect of future prospects for UV curing lies in the integration of digital technologies. Tianhui is exploring the potential of integrating UV curing with digital printing and additive manufacturing processes. This integration offers the possibility of on-demand production, customization, and cost-effective manufacturing solutions. As digital technologies continue to advance, the potential for UV curing to play a pivotal role in the future of manufacturing is immense.

In conclusion, UV curing has undoubtedly transformed the manufacturing landscape, and its future prospects and innovations are poised to further revolutionize how products are made. As a leader in UV curing solutions, Tianhui is committed to driving these advancements and bringing the benefits of UV curing to industries around the world. With continuous research, innovation, and collaboration, Tianhui is shaping the future of manufacturing with UV curing technology.

Conclusion

In conclusion, the advantages of UV curing in manufacturing are undeniable. From improved efficiency and lower energy consumption to reduced waste and emissions, UV curing offers numerous benefits for companies in various industries. As a company with 20 years of experience in the industry, we understand the value of staying ahead of the curve and embracing innovative technologies like UV curing. By harnessing the power of UV curing, manufacturers can not only improve their production processes, but also contribute to a more sustainable and eco-friendly future. It is clear that UV curing is a game-changer for the manufacturing industry, and we are excited to see how it continues to revolutionize the way products are made.