Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Unlocking The Potential Of 365nm LED UV Technology

Are you ready to tap into the limitless possibilities of 365nm LED UV technology? Join us as we delve into the fascinating world of UV technology and explore the endless potential it offers. In this article, we will uncover the innovative applications, benefits, and advancements of 365nm LED UV technology, and how it is revolutionizing various industries. Whether you are a technology enthusiast, a professional in the field, or simply curious about the latest advancements, this article will provide valuable insights into the exciting world of UV technology. Join us as we unlock the potential of 365nm LED UV technology and discover the incredible opportunities it presents.

Introduction to 365nm LED UV Technology

In the world of lighting and technology, new advancements are constantly being made to improve efficiency, performance, and sustainability. One of the latest innovations making waves in the market is 365nm LED UV technology. This cutting-edge technology has the potential to revolutionize various industries, including healthcare, manufacturing, and even consumer products. In this article, we will delve deep into the world of 365nm LED UV technology and explore its potential and applications.

What is 365nm LED UV technology?

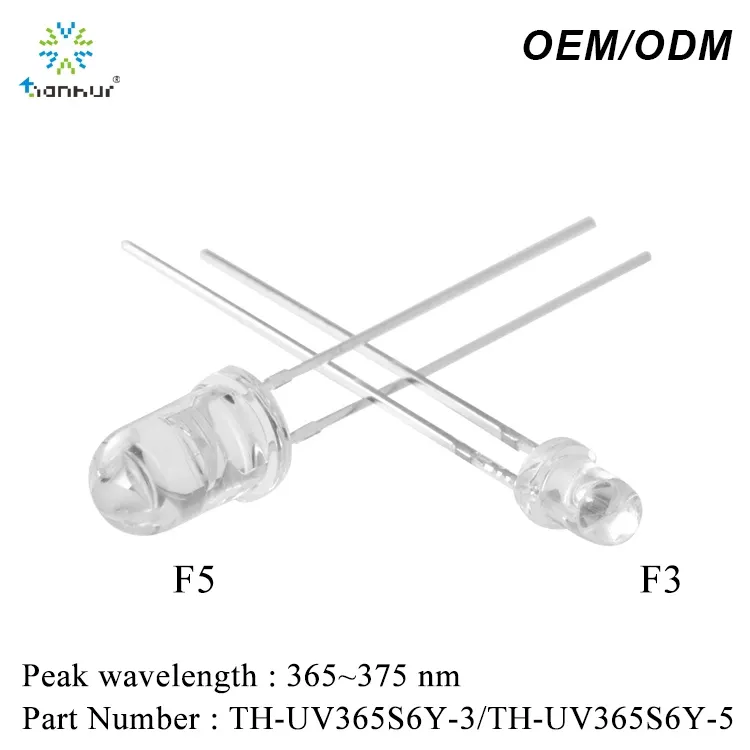

365nm LED UV technology involves the use of light-emitting diodes (LEDs) that emit ultraviolet (UV) light at a specific wavelength of 365 nanometers. This specific wavelength falls within the UV-A spectrum, which is commonly known as black light. Unlike traditional UV lamps, 365nm LED UV technology offers several advantages, including lower energy consumption, longer lifespan, and the absence of harmful mercury. These features make it a more sustainable and eco-friendly alternative to conventional UV lamps.

Applications of 365nm LED UV technology

The versatility and efficiency of 365nm LED UV technology make it applicable across a wide range of industries. In healthcare, 365nm LED UV lights are used for sterilization purposes. The germicidal properties of UV light at 365nm wavelength make it an effective tool for disinfecting surfaces, equipment, and even air in hospitals, laboratories, and other medical facilities. This technology has become increasingly important in the fight against healthcare-associated infections, as it provides a chemical-free and non-toxic method of sterilization.

In the manufacturing industry, 365nm LED UV technology is utilized for curing adhesives, coatings, and inks. The high-intensity UV light at 365nm wavelength triggers a photochemical reaction that causes these materials to harden or cure almost instantly. This improves production efficiency, reduces energy consumption, and eliminates the need for harmful solvents commonly used in traditional curing processes.

Another area where 365nm LED UV technology is gaining traction is in consumer products. From UV curing nail lamps to counterfeit detection devices, the applications of this technology in everyday consumer products are countless. For instance, 365nm LED UV lights are used in nail salons to cure gel nail polish, providing a faster and more efficient manicure experience for customers. In addition, these lights are also used in handheld devices to verify the authenticity of documents, currency, and other valuable items, providing a non-destructive and reliable method of counterfeit detection.

Future potential of 365nm LED UV technology

As technology continues to evolve, the potential of 365nm LED UV technology is boundless. Researchers and manufacturers are constantly exploring new applications for this technology, from water and air purification to agricultural and food processing. The ability of 365nm LED UV light to efficiently and effectively kill bacteria, viruses, and pathogens opens up a world of possibilities for improving public health and safety.

In conclusion, 365nm LED UV technology is a game-changer in the world of lighting and technology. Its efficiency, versatility, and sustainability make it a valuable asset to numerous industries, with the potential to improve processes, products, and overall well-being. As more research and development are invested in this technology, we can expect to see even more innovative applications and advancements in the near future.

Advantages and Applications of 365nm LED UV Technology

In recent years, the use of ultraviolet (UV) technology has become increasingly prevalent in various industries, from healthcare and sanitation to manufacturing and printing. One particular advancement in UV technology that has gained significant attention is the development of 365nm LED UV technology. This cutting-edge technology offers numerous advantages and has a wide range of applications, making it a valuable tool for businesses and organizations across different sectors.

First and foremost, 365nm LED UV technology is highly efficient and cost-effective. Traditional UV lamps often consume large amounts of energy and require frequent maintenance and replacement. In contrast, 365nm LED UV technology is energy-efficient, with lower power consumption and longer lifespan, resulting in reduced operational costs for businesses. Additionally, LED UV technology does not contain harmful mercury, making it a more environmentally friendly option. The long-lasting nature of LED UV technology also reduces the frequency of replacing bulbs, which not only saves money but also decreases downtime for businesses.

In terms of applications, 365nm LED UV technology offers a wide range of uses across various industries. In the healthcare sector, LED UV technology is used for sterilization and disinfection purposes. The 365nm wavelength is particularly effective at destroying bacteria, viruses, and other pathogens, making it an invaluable tool in hospitals, laboratories, and other healthcare facilities. In manufacturing, LED UV technology is utilized for curing adhesives, coatings, and inks, resulting in faster production times and improved product quality. The precision and consistency of 365nm LED UV technology also make it ideal for use in 3D printing and microelectronics, where exacting standards are required.

Another key advantage of 365nm LED UV technology is its ability to provide a controlled and targeted UV output. This precision is essential for applications such as printing and lithography, where the accurate delivery of UV light is crucial for achieving high-quality results. LED UV technology offers a more focused and uniform distribution of UV light, resulting in sharper, more detailed prints and designs. Furthermore, the reduced heat output of LED UV technology compared to traditional UV lamps allows for the use of heat-sensitive substrates and materials, expanding the range of possible applications.

Furthermore, 365nm LED UV technology is also highly versatile, with the capability to be integrated into existing systems and processes. This adaptability allows businesses to upgrade their current equipment and facilities without the need for a complete overhaul, resulting in a smoother transition to the new technology. The flexibility of LED UV technology also means that it can be tailored to specific requirements, ensuring that businesses can optimize its use for their individual needs.

In conclusion, the development of 365nm LED UV technology represents a significant advancement in UV technology, offering numerous advantages and a wide range of applications. From its energy efficiency and cost-effectiveness to its precision and versatility, LED UV technology has the potential to revolutionize various industries. As businesses continue to adopt and harness the power of 365nm LED UV technology, the potential for innovation and improvement across different sectors is vast.

Understanding the Mechanism of 365nm LED UV Technology

In recent years, 365nm LED UV technology has gained significant attention in various industries due to its potential in revolutionizing processes that rely on ultraviolet light. This article aims to pave the way for a thorough understanding of the mechanism behind this innovative technology and its implications for practical applications.

At the core of 365nm LED UV technology lies the use of light-emitting diodes (LEDs) that emit ultraviolet radiation at a wavelength of 365 nanometers. This specific wavelength falls within the UVA spectrum, which is known for its ability to initiate photochemical reactions. Unlike traditional mercury vapor UV lamps, 365nm LED UV technology offers several advantages, such as energy efficiency, instant on/off capabilities, and a longer lifespan. These characteristics make it an attractive option for various industrial and commercial processes.

The key to understanding the mechanism of 365nm LED UV technology lies in its ability to activate photoinitiators, which are chemical compounds that undergo a rapid and specific reaction when exposed to ultraviolet light. In processes such as UV curing, the photoinitiators in the coating or ink undergo a polymerization reaction when exposed to 365nm UV light, leading to the formation of a hardened film. This process is essential in industries such as printing, automotive, electronics, and pharmaceuticals, where rapid and efficient curing is paramount.

Furthermore, the narrow spectral output of 365nm LED UV technology offers precise control over the photopolymerization process, resulting in a higher quality of cured products. This is particularly crucial in industries where consistency and accuracy are vital, such as in the manufacturing of electronic components and medical devices. The ability to achieve precise curing with minimal heat input also serves to minimize the risk of damaging sensitive substrates, further expanding the potential applications of 365nm LED UV technology.

Another aspect of the mechanism of 365nm LED UV technology is its impact on sustainability and environmental considerations. The energy-efficient nature of LED UV technology, coupled with its longer lifespan and lower maintenance requirements, contributes to reduced energy consumption and waste generation. Additionally, the absence of mercury in 365nm LED UV lamps eliminates the environmental hazards associated with traditional UV lamps, aligning with the global push towards greener and safer technologies.

In conclusion, unlocking the potential of 365nm LED UV technology demands a comprehensive understanding of its underlying mechanism. From the activation of photoinitiators to the precise control of polymerization and its environmental implications, the versatility and efficiency of 365nm LED UV technology hold great promise for numerous industries. As research and development continue to advance in this field, the widespread adoption of 365nm LED UV technology is poised to reshape industrial processes and pave the way for a more sustainable and efficient future.

Challenges and Limitations of 365nm LED UV Technology

365nm LED UV technology has revolutionized various industries by unlocking its potential in providing effective and efficient UV light sources. However, despite its numerous advantages, there are several challenges and limitations that come with the use of 365nm LED UV technology.

One of the main challenges of 365nm LED UV technology is its limited range of applications. While 365nm LED UV technology is effective for certain applications such as germicidal disinfection, forensics, and printing, it may not be suitable for all UV curing applications. This limited range of applications can pose a challenge for industries that require a broader spectrum of UV curing capabilities.

Another limitation of 365nm LED UV technology is its potential health and safety concerns. Prolonged exposure to 365nm UV light can cause skin and eye damage, making it important for workers to take precautionary measures when working with 365nm LED UV technology. Additionally, there may be regulatory restrictions on the use of 365nm LED UV technology in certain industries due to its potential health risks.

In addition to its limited range of applications and potential health concerns, 365nm LED UV technology also faces challenges in terms of its energy efficiency and cost-effectiveness. While 365nm LED UV technology is more energy-efficient compared to traditional UV curing methods, it still requires a considerable amount of energy to operate. This can result in higher operational costs for industries that rely on 365nm LED UV technology.

Furthermore, the initial investment required for implementing 365nm LED UV technology can be a limitation for some industries. The cost of purchasing and installing 365nm LED UV equipment and systems may be prohibitive for small businesses or companies with limited budgets. This can hinder the widespread adoption of 365nm LED UV technology across various industries.

Despite these challenges and limitations, there are ongoing efforts to address and overcome them. Researchers and industry professionals are continually working on developing more versatile 365nm LED UV technology that can cater to a wider range of applications. Additionally, advancements in safety measures and regulations are being implemented to ensure the safe use of 365nm LED UV technology in various industries.

In conclusion, while 365nm LED UV technology offers numerous benefits and potentials, it also comes with its fair share of challenges and limitations. However, with ongoing advancements and improvements, it is possible to mitigate these challenges and unlock the full potential of 365nm LED UV technology in various industries.

Future Developments and Innovations in 365nm LED UV Technology

With the increasing demand for UV technology across various industries, the spotlight has been on the potential of 365nm LED UV technology. This has led to continuous developments and innovations in this area, promising a brighter future for a wide range of applications. In this article, we will delve into the latest advancements in 365nm LED UV technology and its impact on various industries.

One of the key developments in 365nm LED UV technology is its enhanced energy efficiency. LED UV technology has already been known for its energy-saving capabilities, but with further advancements, 365nm LED UV systems are becoming even more efficient. This is particularly advantageous for industries such as printing and manufacturing, where UV curing processes are integral to operations. The increased energy efficiency not only leads to cost savings but also contributes to a more sustainable and environmentally friendly approach.

Moreover, the advancements in 365nm LED UV technology also extend to improved performance and reliability. Manufacturers are constantly working towards enhancing the efficacy and consistency of 365nm LED UV systems, offering more reliable and predictable results. This is crucial for industries that rely on precise and consistent UV curing, such as electronics manufacturing and optical lens production. With these developments, businesses can expect higher productivity and reduced maintenance requirements, ultimately leading to improved overall operational efficiency.

Another significant trend in 365nm LED UV technology is the expansion of its application scope. Traditionally, UV curing has been widely utilized in industries such as printing, adhesive bonding, and coatings. However, with the continuous advancements in 365nm LED UV technology, new opportunities are emerging. From medical device manufacturing to food packaging, the potential of 365nm LED UV technology is being unlocked in previously unexplored areas. This expansion opens up new possibilities for innovation and efficiency across diverse industries.

Furthermore, developments in 365nm LED UV technology are also driving the evolution of UV 3D printing. As additive manufacturing continues to gain traction, the demand for high-performance UV curing systems has intensified. 365nm LED UV technology is paving the way for advancements in UV 3D printing, enabling faster curing times, improved material compatibility, and enhanced print quality. This is revolutionizing the 3D printing landscape, opening doors to new capabilities and applications.

In conclusion, the future developments and innovations in 365nm LED UV technology hold great promise for various industries. From energy efficiency and performance enhancements to expanded application possibilities and advancements in UV 3D printing, the impact of these developments is far-reaching. As advancements in 365nm LED UV technology continue to unfold, businesses and industries can look forward to reaping the benefits of enhanced efficiency, productivity, and innovation.

Conclusion

In conclusion, the potential of 365nm LED UV technology is truly groundbreaking. With 20 years of experience in the industry, we have seen the immense capabilities of this technology in various applications. From curing adhesives and coatings to disinfecting surfaces, the possibilities are endless. As we continue to unlock the potential of 365nm LED UV technology, we are excited to see the innovative solutions it will bring to various industries, making processes more efficient and sustainable. With this technology, we are truly on the cusp of a new era in UV technology, and we look forward to the advancements that will come in the future.