Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Unleashing The Power Of 3535 UV LED Technology: A Game-Changer In The Industry

Are you ready to revolutionize your industry? Look no further than the incredible power of 3535 UV LED technology. This game-changing innovation is set to transform the way we approach a wide range of applications, from consumer electronics to medical devices. In this article, we'll explore the potential of this cutting-edge technology and how it is reshaping the industry as we know it. Join us as we uncover the unparalleled opportunities that come with unleashing the power of 3535 UV LED technology.

- Understanding the Benefits of 3535 UV LED Technology

In recent years, 3535 UV LED technology has been making waves in the industry, revolutionizing the way we think about traditional UV lighting. As a leader in the field, Tianhui has been at the forefront of this innovation, understanding the benefits and applications of this cutting-edge technology.

First and foremost, it is crucial to comprehend the significance of 3535 UV LED technology. Unlike conventional UV lights, 3535 UV LED technology offers several key advantages. These include higher energy efficiency, longer lifespan, and improved environmental sustainability. This translates to reduced energy consumption, lower running costs, and minimal environmental impact, making it an attractive option for businesses looking to go green while cutting operational expenses.

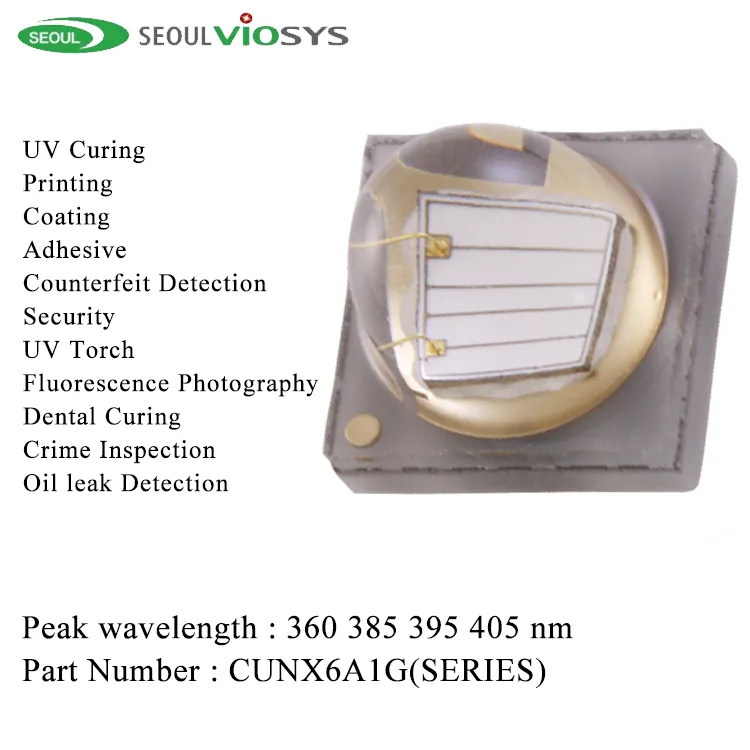

In addition to its cost-effective and eco-friendly nature, 3535 UV LED technology also boasts superior performance compared to traditional UV lights. The precision and controllability of 3535 UV LED technology make it ideal for a wide range of applications, from curing and printing to disinfection and sterilization. The consistent and reliable output of 3535 UV LED technology ensures uniform results, enhancing productivity and quality across various industries.

Moreover, 3535 UV LED technology offers flexibility and customization, allowing for tailored solutions to meet specific requirements. With its compact size and versatile design, 3535 UV LED technology can be seamlessly integrated into existing systems, providing a seamless transition and compatibility with different processes.

One of the key benefits of 3535 UV LED technology is its ability to generate UV light in a narrow wavelength band, making it extremely effective for curing applications. This targeted UV output ensures efficient curing of coatings, inks, adhesives, and other materials, resulting in faster production times, improved adhesion, and overall product quality.

Tianhui has been instrumental in harnessing the power of 3535 UV LED technology, developing innovative products that deliver exceptional performance and reliability. With our in-depth understanding of this advanced technology, we have been able to provide tailored solutions to meet the diverse needs of our clients, setting new benchmarks in the industry.

Looking ahead, the potential of 3535 UV LED technology is boundless, with ongoing research and development driving further improvements and applications. As a leading advocate for this transformative technology, Tianhui continues to push the boundaries, unlocking new possibilities that will shape the future of UV lighting.

In conclusion, the benefits of 3535 UV LED technology are undeniable, offering a game-changing solution for businesses across various sectors. As a trailblazer in this field, Tianhui is committed to maximizing the potential of 3535 UV LED technology, revolutionizing the industry and driving progress towards a more sustainable and efficient future.

- Applications of 3535 UV LED Technology in Various Industries

The use of 3535 UV LED technology is revolutionizing various industries, as it offers a wide range of applications that were previously not possible with traditional lighting technologies. Tianhui, a leading provider of 3535 UV LED technology, is at the forefront of this game-changing innovation.

One of the key areas where 3535 UV LED technology is making a significant impact is in the medical and healthcare industry. The high energy output and precise wavelength control of 3535 UV LED technology make it ideal for various medical applications, such as sterilization, disinfection, and curing. It is widely used in hospitals, clinics, and laboratories to ensure a safe and clean environment for patients and healthcare workers.

Another industry that is benefiting greatly from the advancements in 3535 UV LED technology is the printing and signage industry. The high power and efficiency of 3535 UV LED technology allow for faster and more precise curing of inks and coatings, resulting in higher quality prints and reduced production times. This technology is also used for the production of UV-curable inks and coatings, which are widely used in the printing and packaging industry.

The automotive industry is also embracing the potential of 3535 UV LED technology, particularly in the area of curing and bonding. The ability of 3535 UV LED technology to deliver high-intensity UV light with precise wavelength control makes it ideal for applications such as automotive headlight assembly, windshield bonding, and paint curing. This not only improves the quality and durability of automotive components but also reduces production costs and environmental impact.

Furthermore, the use of 3535 UV LED technology has also expanded into the field of water and air purification. The high-intensity UV light generated by 3535 UV LED technology is effective in destroying bacteria, viruses, and other harmful microorganisms, making it an ideal solution for disinfecting water and air in various industrial and commercial settings. This technology is also increasingly being used in residential water and air purifiers, ensuring a clean and healthy living environment for consumers.

In the field of entertainment and hospitality, 3535 UV LED technology has opened up new possibilities for creating captivating lighting and visual effects. The high power and efficiency of 3535 UV LED technology allow for the creation of dynamic and energy-efficient lighting designs for applications such as stage lighting, architectural lighting, and themed entertainment venues. This technology is also used for UV-curing of special effects coatings and paints, allowing for stunning and durable finishes.

In conclusion, the applications of 3535 UV LED technology in various industries are vast and diverse, offering unprecedented capabilities and opportunities for innovation. As a leading provider of 3535 UV LED technology, Tianhui is committed to driving the adoption and advancement of this game-changing technology, creating a brighter and more sustainable future for industries worldwide.

- Advancements and Innovations in 3535 UV LED Technology

In recent years, 3535 UV LED technology has been making waves in the industry, and the advancements and innovations in this field have proved to be a game-changer. As a leading player in the UV LED industry, Tianhui has been at the forefront of these developments, continuously pushing the boundaries of what is possible with 3535 UV LED technology.

One of the key advancements in 3535 UV LED technology is the increased efficiency and performance of the LEDs. With higher power and better thermal management, these LEDs are now able to deliver more consistent and reliable UV light output. This has opened up new possibilities for a wide range of applications, from curing and printing to sterilization and disinfection. The improved performance of 3535 UV LEDs has enabled manufacturers to achieve higher throughput and quality in their processes, ultimately leading to cost savings and improved product performance.

Another significant innovation in 3535 UV LED technology is the development of new materials and manufacturing processes. Tianhui has been investing heavily in research and development to create new materials that are more efficient at converting electricity into UV light. This has led to significant improvements in the overall efficiency and lifespan of 3535 UV LEDs, making them a more viable and attractive option for a variety of applications.

Furthermore, the miniaturization of 3535 UV LED packages has also been a major breakthrough in the industry. With smaller form factors and higher power densities, these LEDs can now be incorporated into smaller and more compact devices, opening up new opportunities for portable and handheld UV LED solutions. This has been particularly beneficial in the fields of medical and healthcare, where the demand for portable and efficient UV sterilization devices has been on the rise.

In addition to these technological advancements, Tianhui has been actively working on improving the reliability and consistency of 3535 UV LED technology. Through rigorous testing and quality control measures, Tianhui has been able to ensure that their 3535 UV LEDs meet the highest standards for performance and longevity. This has been critical in fostering trust and confidence in the industry, as manufacturers and end-users can rely on the consistency and reliability of Tianhui's 3535 UV LED products.

Looking ahead, the future of 3535 UV LED technology is bright, and Tianhui is committed to staying at the forefront of these developments. With a strong focus on innovation and R&D, Tianhui is continuously exploring new opportunities and applications for 3535 UV LED technology, aiming to drive even further advancements in the industry.

In conclusion, the advancements and innovations in 3535 UV LED technology have truly been a game-changer in the industry. With improved efficiency, new materials, miniaturization, and enhanced reliability, 3535 UV LED technology has opened up new possibilities and opportunities for a wide range of applications. As a leading player in the industry, Tianhui is proud to be at the forefront of these developments, and is dedicated to driving further advancements in 3535 UV LED technology.

- Impact of 3535 UV LED Technology on Manufacturing Processes

In the ever-evolving landscape of manufacturing processes, the impact of 3535 UV LED technology cannot be overstated. As a leading innovator in this field, Tianhui has been at the forefront of harnessing the potential of this cutting-edge technology to revolutionize the industry. In this article, we will delve into the significant impact of 3535 UV LED technology on manufacturing processes and how Tianhui is leading the charge in this transformative era.

3535 UV LED technology has emerged as a game-changer in the industry, offering a plethora of benefits that have redefined traditional manufacturing processes. One of the key advantages of this technology is its energy efficiency, which significantly reduces operational costs and environmental footprint. With the ability to emit powerful UV light at a fraction of the energy consumption of conventional methods, 3535 UV LED technology has paved the way for sustainable and cost-effective manufacturing practices.

Moreover, the precise and controlled nature of 3535 UV LED technology has enhanced the quality and consistency of manufacturing processes. Tianhui has been instrumental in leveraging this aspect of the technology to elevate the standard of our products, ensuring unparalleled precision and reliability. The ability to deliver uniform UV light output with minimal variance has allowed for greater control and accuracy in manufacturing, resulting in superior end-products.

Furthermore, the compact and durable design of 3535 UV LED technology has facilitated its integration into various manufacturing processes, enabling greater flexibility and adaptability. Tianhui has capitalized on this feature to optimize our production processes, streamlining operations and expanding our capabilities. The versatility of 3535 UV LED technology has empowered us to explore new frontiers in manufacturing, leading to enhanced productivity and innovation.

In addition, the long lifespan and low maintenance requirements of 3535 UV LED technology have proven to be instrumental in reducing downtime and enhancing overall efficiency. Tianhui has reaped the benefits of this aspect by minimizing interruptions to our manufacturing processes, maximizing output, and ensuring consistent performance. The reliability and longevity of 3535 UV LED technology have played a pivotal role in our commitment to delivering excellence in manufacturing.

As a pioneering force in the industry, Tianhui has not only embraced the potential of 3535 UV LED technology but has also been instrumental in shaping its evolution. Through relentless research and development, we have pushed the boundaries of this technology, continuously striving to unlock its full potential. This dedication has culminated in the creation of innovative solutions that have redefined manufacturing processes, setting new benchmarks for the industry.

In conclusion, the impact of 3535 UV LED technology on manufacturing processes is undeniable, and Tianhui has been a driving force in harnessing its transformative power. The energy efficiency, precision, versatility, and reliability of this technology have revolutionized the industry, and Tianhui has been at the forefront of this revolution. As we continue to push the boundaries of innovation, we are committed to unleashing the full potential of 3535 UV LED technology and redefining the future of manufacturing.

- Future Possibilities and Potential of 3535 UV LED Technology in the Industry

In recent years, the development of UV LED technology has made significant strides in various industries, and the 3535 UV LED technology has emerged as a potential game-changer. This article aims to delve into the future possibilities and potential of 3535 UV LED technology in the industry, focusing on how it can revolutionize processes and applications across different sectors.

As a leading innovator in UV LED technology, Tianhui has been at the forefront of harnessing the power of 3535 UV LED technology. With a commitment to pushing the boundaries of what is possible, Tianhui has been instrumental in developing cutting-edge solutions that leverage the unique capabilities of 3535 UV LED technology.

The 3535 UV LED technology offers several key advantages that set it apart from traditional UV light sources. Its compact size and high energy efficiency make it an ideal choice for a wide range of applications, including printing, curing, disinfection, and more. With a longer lifespan and lower maintenance requirements, 3535 UV LED technology presents an opportunity for businesses to enhance their operational efficiency and reduce overall costs.

One of the most significant potential applications of 3535 UV LED technology lies in the field of printing. The precise control and consistency of UV LED output make it particularly well-suited for high-resolution printing, allowing for improved print quality and faster production speeds. Additionally, the ability to cure inks and coatings instantly with UV LED technology results in reduced production time and enhanced durability of printed materials.

Furthermore, the potential for 3535 UV LED technology to revolutionize the disinfection process is a particularly compelling prospect in the context of current global health concerns. With its ability to provide rapid and effective disinfection without the use of harmful chemicals, UV LED technology has the potential to significantly improve sanitation practices in healthcare facilities, food processing plants, and other critical environments.

In the realm of industrial applications, 3535 UV LED technology holds promise for enhancing the efficiency of manufacturing processes. From bonding and sealing to surface curing and coating, the precision and reliability of UV LED technology can streamline production workflows and improve product quality. Its ability to deliver targeted and consistent UV output enables manufacturers to achieve greater control and consistency in their processes.

As the industry continues to evolve, the potential of 3535 UV LED technology is only beginning to be fully realized. With ongoing advancements in material science and engineering, the capabilities of UV LED technology are expected to expand even further, opening up new possibilities for innovation and discovery.

In conclusion, the future possibilities and potential of 3535 UV LED technology in the industry are vast and promising. As a leading proponent of UV LED technology, Tianhui is dedicated to unlocking the full potential of 3535 UV LED technology and empowering businesses to thrive in an ever-changing landscape. With its commitment to innovation and excellence, Tianhui is poised to shape the future of UV LED technology and drive meaningful progress across diverse industries.

Conclusion

In conclusion, the emergence of 3535 UV LED technology has ushered in a new era in the industry, revolutionizing the way we approach UV curing and disinfection processes. With 20 years of experience in the industry, we have witnessed firsthand the transformative power of this technology and its game-changing impact on various applications. As we continue to harness the potential of 3535 UV LED technology, we are confident that it will continue to drive innovation, efficiency, and sustainability in the industry, ultimately benefiting businesses and consumers alike. The future is bright with the possibilities that this technology brings, and we are excited to be at the forefront of this exciting evolution.