Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

The Three Major Factors of LED Lamp Beads Actually Affect the Quality of LED Lamps

2022-10-10

Tianhui

114

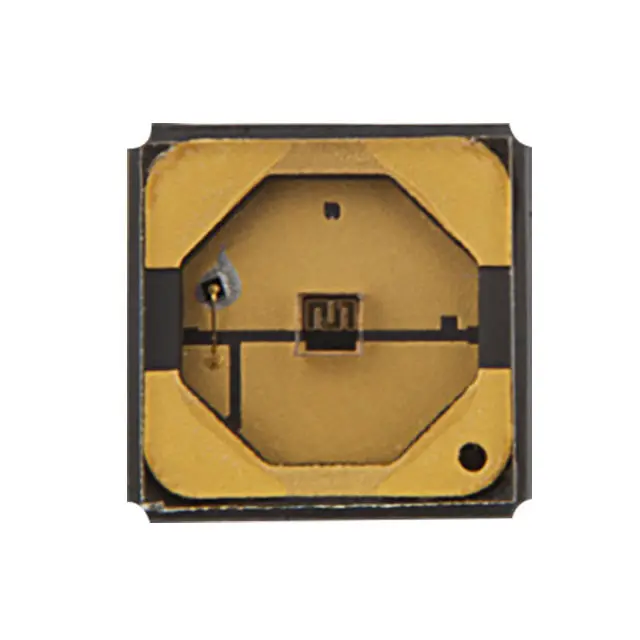

The three important factors of LED lamp beads have deeply affected the quality of LED lamps. Let s take a look at the detailed reasons together: the data detected by a single LED lamp bead on the aging board, and assembled the LED lamp beads into one as one The data detected when the lamp is aging, it must be a bit different. The size of these differences depends on the electrical parameters and the design of the lamps during LED work, as well as the environment used by the lamps. 1. The quality of LED lamp beads for LED lamp beads is a critical factor. For example, the same is represented by the chip of the chip of the chip 14mil, and the LED lamp beads encapsulated by the bottom gum and white glue and packaging glue made of ordinary epoxy resin, which lit a single one in an environment of 30 degrees. After thousands of hours, the attenuated data is 70%of the optical decay; if the D type D low -decaying glue is encapsulated, in the same aging environment, the 1,000 -hour light decay is 45%; , 1,000-hour light decay is 12%; if category B is encapsulated in low-decreased glue, in the same aging environment, thousands of hours of light decay of -3%; if Class A is low-declining glue, in the same aging environment, thousands of hours of light in the same aging environment, thousands of hours of light in the same aging environment, thousands of hours of light in the same aging environment, thousands of hours of light in the same aging environment, thousands of hours of light for thousands of hours of light. What is the difference between the decay of -6%. Why does the different packaging process cause a big difference? One of the most important reasons is that the LED chip is afraid of heat. Occasionally heated more than one hundred degrees in a short period of time, and the impact is not great. I am afraid that it will be at high temperature for a long time. It is a great damage to the LED chip. Generally speaking, the thermal conductivity of ordinary epoxy resins is small. Therefore, when LED chips are lit, LED chips should emit heat, and ordinary epoxy resin thermal conductivity is limited. When the temperature of the LED bracket is 45 degrees, the temperature of the chip center in the LED lamp bead may exceed 80 degrees. The temperature node of the LED is actually 80 degrees, so when the LED chip works at the temperature of the temperature, it is very suffering, which speeds up the aging of LED light sources. When the LED chip is working, the center temperature generates a high temperature of 100 degrees. It can immediately use the standing pin to the heat to reduce the heat, thereby reducing the damage to it. Therefore, when the temperature of the LED lamp beads is 60 degrees, the temperature of its chip center may be just 61 degrees. As can be seen from the above data, the LED lamp beads who choose what kind of packaging process are selected, and the light decision of the LED lamps directly determines the light decision of LED lamps. 2. The environment and temperature of LED light source work According to the data of a single LED light source, if the LED light source has only one lighting work, at the same time, the environmental temperature it is located is 30 degrees, then the single LED light source work is working The temperature of the shelf will not exceed 45 degrees. At this time, the life of this LED will be ideal. If there are 100 LED light sources on the work at the same time, the interval between them is only 11.4mm, then the bracket temperature of the LED light source around the lamp pile may not exceed 45 degrees, but those LEDs in the middle of the lamp piles will not The light source may reach 65 degrees high temperature. At this time, the LED light source is a test. Then, those LED light sources gathered in the middle will theoretically faster, and the LED light sources around the lamp pile will be slower. But if LED lamp beads are more than 25mm apart, then the calories they divert will not accumulate so much. At this time, the temperature of each LED lamp beads should be less than 50 degrees, which is more conducive to the normal work of LED. If the environment of the LED work is in a relatively cold place, the average temperature of the whole year may be only about 15 degrees or smaller, then for LED, life span is longer. Or, when LED works, there is a small fan next to it and help it to remove the heat. This will also help the life of the LED. Everyone should know that LED lamp beads are afraid of heat. The higher the temperature, the shorter the LED life, the lower the temperature, and the longer the LED life. The working temperature of LED ideal is of course between 5 or zero degrees negative. But this is basically impossible. Therefore, after we understand the ideal working parameters of LED lamp beads, we should strengthen the function of heat conduction and heat dissipation when designing lamps as much as possible when designing lamps as much as possible. Anyway, the lower the temperature, the longer the LED life span. Third, the working electrical parameter design of LED lamp beads According to the experimental results, the lower the LED white light, the smaller the emission heat is, of course, the smaller the brightness. According to the survey, the design of the LED solar lighting circuit, the driver current of LED is generally only 5-10mA; the large number of lamps used in the lamps, such as more than 500 or more And the generally popular LED application lighting driving current is only 15-18mA, and few people designed the current to more than 20mA. The experimental results also showed that under the driver current of 14mA, and the lid was not ventilated, the air temperature in it reached 71 degrees, low decline products, 1,000 -hour light decay, 2000 hours of light decay of 3% to 3%, 3% decaying is 3%. This shows that this low -declining LED white light has reached its maximum use in such an environment. No matter how big it is, it is a damage to it. Because the aging board used does not have a heat dissipation function, the heat generated during LED is basically unable to transmit it outside. The experiment proved this. The air temperature in the old panel has reached a high temperature of 101 degrees. The surface temperature of the lid on the old panel is only 53 degrees, which is dozens of degrees. This shows that the designed plastic lid basically does not have the function of conducting heat and heat dissipation. But in the general lamp design, considering the function of conducting heat and heat dissipation. Therefore, in summary, the design of the working electrical parameters of LED lamp beads should be based on the actual situation. If the heat -conducting heat dissipation function of the lamp is very good, it is okay to increase the driving current of LED white lights, because the LED lamp beads work generate. The heat can be exported out of the moment, and there is no damage to the LED, which is the best care for the LED. On the contrary, if the heating and heat dissipation function of the lamp is sloppy, it is best to design the circuit less and let it put some heat.

Author: Tianhui-Air Disinfection

Author: Tianhui-UV Led manufacturers

Author: Tianhui-UV water disinfection

Author: Tianhui-UV LED Solution

Author: Tianhui-UV Led diode

Author: Tianhui-UV Led diodes manufacturers

Author: Tianhui-UV Led module

Author: Tianhui-UV LED Printing System

Author: Tianhui-UV LED mosquito trap

GET IN TOUCH WITH Us

You can find us here