Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

The Power Of LED Curing: Revolutionizing Industrial Processes

Have you ever wondered how industrial processes are being revolutionized in the modern age? One significant advancement lies in the power of LED curing. This cutting-edge technology is reshaping the way industrial products are manufactured and finished, offering a range of benefits from increased efficiency to reduced environmental impact. In this article, we will delve into the transformative impact of LED curing and the ways it is changing the industrial landscape. If you’re curious to learn more about this game-changing innovation, keep reading to discover the power of LED curing.

Introduction to LED Curing Technology

LED curing technology has been revolutionizing industrial processes with its powerful and efficient capabilities. This innovative technology has become increasingly popular in various industries such as automotive, electronics, printing, and packaging, due to its significant advantages over traditional curing methods. In this article, we will provide a detailed introduction to LED curing technology and explore its impact on industrial processes.

LED curing technology, also known as light-emitting diode curing, is a highly efficient and environmentally friendly method of curing materials such as adhesives, coatings, and inks. Unlike traditional curing methods that utilize heat or solvent-based systems, LED curing uses energy-efficient light emitters to initiate a chemical reaction that bonds and cures the materials. This process offers numerous benefits, including faster curing times, reduced energy consumption, and lower operating costs.

Tianhui, a leading provider of LED curing solutions, has been at the forefront of developing and implementing this advanced technology. With a strong focus on innovation and sustainability, Tianhui has established itself as a key player in the industry, offering a wide range of LED curing systems that are designed to optimize production processes and improve overall efficiency. By leveraging the power of LED curing, Tianhui is driving positive change in industrial processes worldwide.

One of the key advantages of LED curing technology is its ability to deliver precise and uniform curing. Traditional curing methods often result in uneven curing, leading to product defects and inconsistencies. LED curing systems, on the other hand, produce a consistent and reliable light output, ensuring uniform curing across the entire surface of the material. This level of precision is essential for industries that require high-quality and error-free production.

In addition to its precision, LED curing technology is also known for its instant on/off capability, which allows for immediate curing when the light source is activated, and instant cessation of curing when the light source is turned off. This rapid curing process significantly reduces production times and increases overall throughput, leading to improved productivity and cost savings. Furthermore, LED curing systems do not produce harmful ozone or emit excessive heat, making them safe for the environment and for use in temperature-sensitive applications.

Tianhui's commitment to sustainability is reflected in its LED curing solutions, which are designed to minimize environmental impact and enhance operational efficiency. By providing energy-efficient and long-lasting LED curing systems, Tianhui is helping industries reduce their carbon footprint and achieve their sustainability goals. With a focus on continuous research and development, Tianhui is dedicated to pushing the boundaries of LED curing technology and raising the standards for industrial processes.

In conclusion, LED curing technology is a game-changer in the industrial landscape, offering unmatched efficiency, precision, and sustainability. As industries continue to adopt this innovative technology, the demand for high-quality and reliable LED curing solutions will only grow. Tianhui's leadership in LED curing technology positions the company as a driving force in this transformative movement, and their commitment to delivering superior LED curing systems is set to reshape industrial processes for years to come.

Advantages of LED Curing in Industrial Processes

As industrial processes continue to evolve, the advantages of LED curing are becoming increasingly apparent. Companies around the world are recognizing the numerous benefits that LED curing brings to their manufacturing operations, and it is revolutionizing the way they approach their production processes.

LED curing, short for light-emitting diode curing, has become a popular choice in industrial processes due to its numerous advantages. Unlike traditional curing methods, which often rely on heat or chemicals to cure products, LED curing uses energy-efficient LED lights to rapidly cure adhesives, coatings, and inks. This not only speeds up the production process but also reduces energy consumption and environmental impact.

One of the main advantages of LED curing is its energy efficiency. LED lights consume significantly less energy than traditional curing methods, making them a cost-effective and sustainable choice for industrial applications. By using less energy, companies can reduce their overall production costs and decrease their environmental footprint, aligning with the growing global focus on sustainability and energy conservation.

Tianhui, a leading provider of LED curing solutions, has been at the forefront of this revolution. With our state-of-the-art LED curing technology, we have helped countless industrial businesses improve their production processes and achieve greater efficiency. Our LED curing systems are designed to deliver high-performance curing while minimizing energy consumption, making them an ideal choice for companies looking to enhance their sustainability efforts.

In addition to energy efficiency, LED curing also offers superior performance and versatility. LED lights can be precisely controlled to deliver the exact amount of curing energy needed, resulting in consistent and high-quality results. This level of precision is particularly valuable in industries such as automotive, electronics, and packaging, where the quality of the cured products is crucial.

Furthermore, LED curing systems have a longer lifespan and require minimal maintenance compared to traditional curing methods. This means that companies can minimize downtime and reduce overall operating costs, providing a significant advantage for businesses looking to maximize their productivity and profitability.

Another notable advantage of LED curing is its environmental impact. Unlike traditional curing methods that may rely on harmful chemicals or emit excessive heat, LED curing is a much cleaner and safer process. This not only creates a healthier work environment for employees but also reduces the overall environmental impact of the production process.

Overall, the advantages of LED curing in industrial processes are clear. From energy efficiency and superior performance to sustainability and environmental benefits, LED curing is revolutionizing the way companies approach their manufacturing operations. As a leading provider of LED curing solutions, Tianhui is committed to helping industrial businesses harness the power of LED curing to achieve greater efficiency, sustainability, and success.

In conclusion, LED curing is an innovative and game-changing technology that is transforming industrial processes for the better. By embracing LED curing, companies can improve their production processes, reduce costs, and minimize their environmental impact, ultimately achieving a competitive edge in today's evolving industrial landscape.

Applications of LED Curing in Various Industries

In recent years, the applications of LED curing technology have expanded rapidly, transforming various industries and revolutionizing industrial processes. Tianhui, a leading provider of LED curing solutions, has been at the forefront of this revolution, offering cutting-edge technology to businesses around the world.

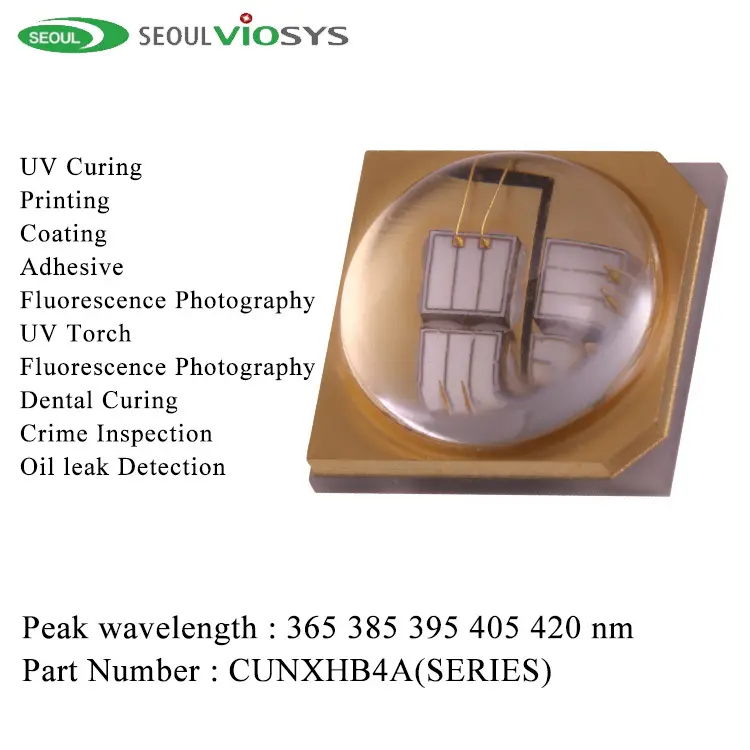

LED curing is a process that uses light-emitting diodes (LEDs) to cure adhesives, coatings, and inks. This technology has numerous advantages over traditional curing methods, including faster curing times, lower energy consumption, and improved process control. As a result, LED curing has become increasingly popular across a wide range of industries, from automotive manufacturing to electronics assembly.

In the automotive industry, LED curing has revolutionized the painting and coating processes, allowing for faster production cycles and higher quality finishes. Tianhui's LED curing systems are capable of curing automotive coatings in a fraction of the time required by traditional methods, resulting in significant cost savings and improved productivity for manufacturers.

In the electronics industry, LED curing has become essential for the production of printed circuit boards (PCBs) and other electronic components. The precise control and high-intensity output of Tianhui's LED curing systems make them ideal for curing adhesives and coatings on sensitive electronic materials, ensuring a high-quality finish and reliable performance.

LED curing technology has also made significant advancements in the medical and pharmaceutical industries, where precise and controlled curing processes are essential for the production of medical devices and pharmaceutical packaging. Tianhui's LED curing systems offer the perfect solution for these industries, providing the precise control and high-intensity output required for curing adhesives and coatings on medical and pharmaceutical products.

In the packaging industry, LED curing has become a game-changer, offering fast and efficient curing of inks and coatings on a wide range of packaging materials. Tianhui's LED curing systems are capable of curing inks and coatings on materials such as paper, cardboard, and plastic, allowing for high-speed production and improved product quality.

Overall, the applications of LED curing in various industries are vast and continue to expand as the technology advances. As a pioneer in LED curing technology, Tianhui is dedicated to providing innovative solutions to meet the evolving needs of businesses across the globe. With a focus on efficiency, productivity, and quality, Tianhui's LED curing systems are transforming industrial processes and setting new standards for the future of manufacturing.

Impact of LED Curing on Efficiency and Productivity

In the world of industrial processes, efficiency and productivity are paramount. Any innovation that can expedite and improve these aspects is highly sought after. One such innovation is the introduction of LED curing technology, which has quickly gained traction in various industries for its significant impact on efficiency and productivity.

LED curing refers to the process of using light-emitting diodes (LEDs) to cure adhesives, coatings, inks, and other materials. This technology has steadily gained popularity as a replacement for traditional curing methods, such as UV lamps and thermal curing, due to its numerous advantages in industrial applications. The impact of LED curing on efficiency and productivity has been nothing short of revolutionary.

One key advantage of LED curing is its energy efficiency. Compared to traditional curing methods, LED curing requires significantly less energy to operate, resulting in lower operational costs and reduced environmental impact. This makes it an attractive option for companies looking to improve their sustainability while also cutting down on expenses. As a leading provider of LED curing solutions, Tianhui has been at the forefront of delivering energy-efficient and cost-effective products to its clients, further solidifying its position as an industry leader in this space.

Additionally, the use of LED curing technology has been shown to significantly reduce curing times. LED light sources can quickly and uniformly cure materials, resulting in faster production cycles and increased throughput. This not only enhances overall efficiency but also allows companies to meet tight deadlines and production targets with ease. Tianhui’s LED curing solutions have been instrumental in helping numerous clients streamline their production processes and achieve remarkable time savings, ultimately boosting their productivity and bottom line.

Furthermore, LED curing offers superior quality and performance compared to traditional curing methods. The precise control and consistency of LED light enable uniform curing across the entire surface of the material, leading to improved product quality and reliability. This, in turn, reduces the need for rework and ensures that products meet stringent industry standards. Tianhui’s cutting-edge LED curing technology has empowered its clients to elevate the quality of their output, enhancing their reputation and competitiveness in the market.

In conclusion, the impact of LED curing on efficiency and productivity cannot be overstated. This innovative technology has transformed industrial processes, offering substantial energy savings, faster curing times, and superior quality, all of which culminate in heightened efficiency and productivity. As a pioneer in LED curing solutions, Tianhui continues to lead the way in driving these advancements across various industries, empowering its clients to thrive in an increasingly competitive landscape. With LED curing as the driving force, the future of industrial processes looks brighter than ever.

Future Developments in LED Curing Technology

As technology continues to advance, LED curing technology has become a game changer in industrial processes, and the future developments in this field are expected to revolutionize the way we approach manufacturing and production. As a leading innovator in this industry, Tianhui has been at the forefront of these advancements, constantly pushing the boundaries of what is possible with LED curing technology.

LED curing technology has already proven to be a much more efficient and environmentally friendly alternative to traditional methods of curing in various industrial processes. The use of LED curing has significantly reduced energy consumption, decreased production times, and eliminated the need for harmful chemicals typically associated with traditional curing methods. As a result, many industries, including printing, automotive, electronics, and medical devices, have adopted LED curing technology as the preferred method for their manufacturing processes.

Looking ahead, the future developments in LED curing technology are poised to further enhance its capabilities and applications. One of the most exciting developments on the horizon is the integration of smart technology into LED curing systems. This will allow for greater control and precision in the curing process, resulting in even higher quality and more uniform end products. Tianhui is already at the forefront of this innovation, developing cutting-edge LED curing systems that are easily integrated into smart manufacturing processes.

Moreover, the future developments in LED curing technology are also focused on expanding the range of materials that can be effectively cured using LED technology. Currently, LED curing is widely used for the curing of inks, coatings, adhesives, and sealants. However, ongoing research and development efforts are geared towards broadening the scope to include a wider variety of materials, such as composites, plastics, and even certain types of metals. This expansion will open up new possibilities for industries to utilize LED curing technology in their manufacturing processes, further solidifying its position as the go-to curing method.

In addition, the future of LED curing technology also promises advancements in the form of increased power and efficiency. As LED technology continues to improve, we can expect to see more powerful and energy-efficient LED curing systems that are capable of handling larger volumes of production while reducing overall operational costs. These advancements will make LED curing technology an even more attractive option for industries looking to improve their bottom line while reducing their environmental impact.

As a leader in LED curing technology, Tianhui is committed to staying at the forefront of these future developments. Our team of engineers and researchers are dedicated to pushing the boundaries of what is possible with LED curing technology, and we are constantly working to bring the latest advancements to our customers. With a focus on smart technology integration, expanding material capabilities, and increasing power and efficiency, Tianhui is poised to lead the way in revolutionizing industrial processes through LED curing technology.

In conclusion, the future developments in LED curing technology hold great promise for the manufacturing industry. With its many benefits, including energy efficiency, environmental friendliness, and versatility, LED curing technology is set to become the standard for curing processes across a wide range of industries. As a leading innovator in this field, Tianhui is dedicated to driving these advancements forward, and we are excited to see the positive impact that LED curing technology will continue to have on industrial processes in the years to come.

Conclusion

In conclusion, the power of LED curing is truly revolutionizing industrial processes. With its ability to provide more efficient, cost-effective, and environmentally friendly solutions, LED curing is transforming the way companies approach their manufacturing and production processes. As a company with 20 years of experience in the industry, we have witnessed firsthand the incredible impact that LED curing has had on our operations and those of our clients. We are excited to continue pushing the boundaries of innovation in this field and look forward to seeing the continued advancements that LED curing will bring to industrial processes in the future.