Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

The Power And Potential Of 365 Nm UV LED Technology

Welcome to our exploration of the incredible capabilities of 365 nm UV LED technology. In this article, we will delve into the power and potential of this innovative technology, and how it is revolutionizing various industries. Discover the numerous applications and benefits of 365 nm UV LED technology, and gain insight into how it is shaping the future of UV light sources. Join us as we uncover the groundbreaking advancements and possibilities of this cutting-edge technology.

- Understanding the Basics of 365 nm UV LED Technology

365 nm UV LED technology is a cutting-edge innovation that has revolutionized various industries by providing a more efficient and cost-effective alternative to traditional UV light sources. Understanding the basics of this technology is crucial for those looking to harness its power and potential in their respective fields. In this article, we will explore the ins and outs of 365 nm UV LED technology and its implications for a wide range of applications.

At its core, 365 nm UV LED technology utilizes light-emitting diodes to produce ultraviolet radiation with a specific wavelength of 365 nanometers. This specific wavelength falls within the UVA spectrum and is known for its ability to induce photochemical reactions, making it invaluable for applications such as curing, sterilization, and fluorescent detection. Unlike traditional UV lamps, UV LED technology is more energy-efficient, has a longer lifespan, and emits little to no heat, making it a more sustainable and practical choice for various industries.

One of the key advantages of 365 nm UV LED technology is its ability to provide targeted and consistent UV output. This precision allows for more accurate and reliable results in applications such as UV curing, where uniform exposure is essential for the proper curing of adhesives, coatings, and inks. Additionally, the instant on/off capability of UV LED technology enables greater control over the curing process, resulting in increased production efficiency and reduced energy consumption.

Furthermore, the compact size and customizable nature of UV LED systems make them suitable for integration into automated processes and portable devices. This flexibility opens up opportunities for UV LED technology to be utilized in new and innovative ways, such as in medical devices, water purification systems, and counterfeit detection tools. The potential for 365 nm UV LED technology to shape the future of these and many other industries is vast and exciting.

In the realm of environmental sustainability, 365 nm UV LED technology also shines. Its energy efficiency and reduced environmental impact, coupled with its long operational lifespan, make it a greener alternative to traditional UV light sources. As the world continues to prioritize sustainability, the adoption of UV LED technology is poised to play a significant role in driving positive change.

In conclusion, understanding the basics of 365 nm UV LED technology is essential for anyone looking to tap into its power and potential. From its precise and consistent UV output to its versatility and sustainability, this technology offers numerous benefits across various industries. As the demand for efficient and eco-friendly solutions grows, the significance of 365 nm UV LED technology is only set to increase, paving the way for a brighter and more sustainable future.

- Applications and Advantages of 365 nm UV LED Technology

In recent years, the use of 365 nm UV LED technology has gained significant traction in various industries due to its diverse applications and numerous advantages. This advanced technology offers a wide range of benefits, from improved efficiency and cost-effectiveness to environmental friendliness. In this article, we will explore the applications and advantages of 365 nm UV LED technology across different sectors.

One of the key applications of 365 nm UV LED technology is in the field of industrial manufacturing. This technology is widely used for curing adhesives, coatings, and inks, as it provides a fast and efficient curing process. Unlike traditional curing methods, 365 nm UV LED technology does not require the use of harmful solvents or chemicals, making it an environmentally friendly option. Additionally, the use of UV LED technology results in reduced energy consumption and lower operating costs, making it a cost-effective solution for industrial manufacturing processes.

Another notable application of 365 nm UV LED technology is in the healthcare and medical industry. UV LED technology is used for disinfection and sterilization purposes, as it can effectively kill bacteria, viruses, and other harmful microorganisms. This technology is particularly beneficial in healthcare settings, where maintaining a clean and sterile environment is crucial for patient safety. With the use of 365 nm UV LED technology, healthcare facilities can ensure thorough and efficient disinfection without the need for harsh chemicals or prolonged exposure times.

Furthermore, 365 nm UV LED technology is also widely utilized in the field of printing and graphics. UV LED printers offer high-quality printing results with superior color accuracy and fast curing times. The use of UV LED technology in printing applications also enables printing on a wide range of substrates, including paper, plastic, and metal, opening up new possibilities for creative and innovative designs. Additionally, UV LED printing is an environmentally friendly option, as it eliminates the need for VOC-emitting inks and reduces energy consumption during the printing process.

The advantages of 365 nm UV LED technology are numerous and diverse. One of the key advantages of this technology is its energy efficiency. UV LED technology consumes significantly less energy compared to traditional UV lamps, resulting in reduced operating costs and lower environmental impact. Additionally, UV LED technology has a longer lifespan and requires minimal maintenance, leading to increased productivity and cost savings for businesses. Furthermore, the use of UV LED technology eliminates the need for harmful chemicals and solvents, making it a safer and more sustainable option for various applications.

In conclusion, the power and potential of 365 nm UV LED technology are evident across a wide range of industries. From industrial manufacturing to healthcare and printing, this advanced technology offers numerous applications and advantages that make it a valuable and efficient solution for businesses. As the demand for eco-friendly and cost-effective technologies continues to grow, 365 nm UV LED technology is poised to play a pivotal role in shaping the future of various industries.

- Challenges and Developments in 365 nm UV LED Technology

365 nm UV LED technology has been making significant strides in recent years, as it offers a wide range of potential applications in various industries. However, the development of this technology has not been without its challenges. In this article, we will explore the current challenges and developments in 365 nm UV LED technology, and how it is poised to revolutionize various fields.

One of the key challenges in 365 nm UV LED technology is achieving high power output. Historically, UV LEDs have struggled to produce sufficient power at the 365 nm wavelength, limiting their usefulness in industrial and commercial applications. However, recent advancements in materials and manufacturing processes have enabled the development of high-power 365 nm UV LEDs, offering new possibilities for applications such as curing, disinfection, and phototherapy.

Another challenge is the need for reliable and efficient UV LED drivers. Driving UV LEDs at the 365 nm wavelength requires specialized electronics to ensure stable and consistent performance. Manufacturers have been working on developing drivers that can deliver the high current and precise control needed for 365 nm UV LEDs, addressing this crucial aspect of the technology.

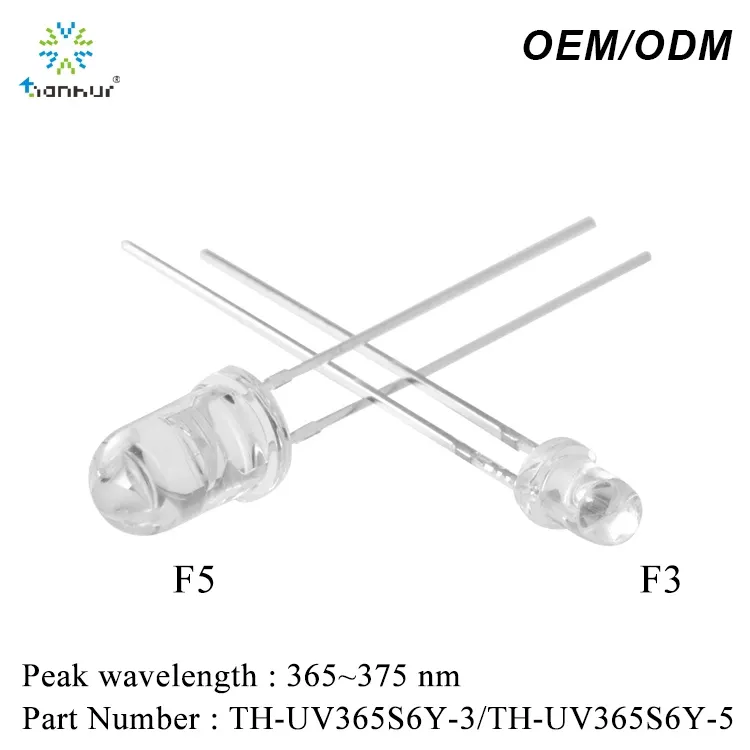

Furthermore, the development of reliable and durable UV LED packaging has been a focus of the industry. The packaging of UV LEDs is critical in ensuring long-term performance and stability. With 365 nm UV LEDs being used in various environments and applications, such as water and air purification, reliable packaging is essential to withstand harsh conditions and ensure consistent performance over time.

Despite these challenges, significant developments have been made in 365 nm UV LED technology. The advancements in semiconductor materials and manufacturing processes have enabled the production of high-power 365 nm UV LEDs, expanding their potential applications. Additionally, improvements in UV LED driver technology have enhanced the efficiency and control of 365 nm UV LEDs, making them more viable for high-demand applications.

Moreover, the development of advanced packaging materials and techniques has resulted in more reliable and durable 365 nm UV LEDs. These developments have paved the way for the integration of UV LED technology in a wide range of industries, including medical, industrial, and consumer electronics.

In conclusion, 365 nm UV LED technology has made significant progress in recent years, overcoming various challenges to offer new possibilities for a wide range of applications. The development of high-power UV LEDs, efficient drivers, and reliable packaging has positioned 365 nm UV LED technology as a powerful and versatile tool for industries seeking to harness the power of UV light. As the technology continues to evolve, we can expect to see even more advancements and applications in the near future.

- Future Trends and Opportunities in 365 nm UV LED Technology

The development of 365 nm UV LED technology has opened up new opportunities and future trends in various industries. From curing and disinfection to medical and industrial applications, this innovative technology has the potential to revolutionize the way we approach UV LED technology.

One of the key advantages of 365 nm UV LED technology is its ability to provide precise and targeted UV light. This wavelength is particularly effective for curing adhesives, coatings, and inks, making it a valuable tool in the manufacturing and printing industry. Unlike traditional UV lamps, 365 nm UV LEDs are more energy-efficient and have a longer lifespan, making them a cost-effective and sustainable solution for UV curing applications.

In addition to curing, 365 nm UV LED technology also has significant implications for disinfection and sterilization. With the recent global health crisis, there has been a growing demand for effective and efficient disinfection solutions. 365 nm UV LEDs have been shown to effectively inactivate a wide range of pathogens, including bacteria, viruses, and fungi. This technology can be used in water treatment, air purification, and surface disinfection, offering a safe and environmentally friendly alternative to chemical disinfectants.

Furthermore, 365 nm UV LED technology has the potential to revolutionize medical and healthcare practices. From phototherapy and wound healing to diagnostic equipment and medical imaging, the precise and controlled UV light produced by 365 nm UV LEDs can play a crucial role in improving patient outcomes and advancing medical research. In particular, the ability to deliver targeted UV light at a specific wavelength opens up new possibilities for treating skin conditions, infections, and other medical ailments.

Beyond its current applications, the future trends of 365 nm UV LED technology are promising. As research and development in UV LED technology continue to advance, we can expect to see further improvements in efficiency, performance, and scalability. This will likely lead to the development of new products and solutions that leverage the benefits of 365 nm UV LED technology, expanding its reach across various industries and applications.

Moreover, the increasing demand for sustainable and environmentally friendly technologies is driving the growth of 365 nm UV LED technology. With its energy efficiency, long lifespan, and minimal environmental impact, 365 nm UV LED technology aligns with the growing focus on sustainability and green practices. As a result, we can anticipate a growing adoption of this technology across different sectors, further driving innovation and investment in UV LED technology.

In conclusion, the power and potential of 365 nm UV LED technology are vast and varied. From its current applications in curing and disinfection to its future trends and opportunities in medical, industrial, and environmental fields, this innovative technology is poised to make a significant impact on various industries. As research and development in UV LED technology continue to progress, we can expect to see further advancements and new possibilities for harnessing the power of 365 nm UV LED technology.

- Harnessing the Power of 365 nm UV LED Technology in Various Industries

In recent years, there has been a surge in the use of 365 nm UV LED technology across various industries. This innovative technology has been harnessed for its powerful and potential capabilities, providing a range of benefits from increased efficiency to improved product quality. As the demand for UV LED technology continues to grow, it is clear that this technology is revolutionizing the way many industries operate.

One of the key advantages of 365 nm UV LED technology is its ability to provide a consistent and reliable source of UV light. Traditional UV lamps often suffer from degradation over time, leading to fluctuations in output and reduced effectiveness. In contrast, 365 nm UV LED technology offers a stable and long-lasting UV light source, ensuring consistent performance over time. This reliability is crucial for industries such as manufacturing and printing, where precision and accuracy are paramount.

Another significant benefit of 365 nm UV LED technology is its energy efficiency. Unlike traditional UV lamps, which can be energy-intensive and costly to operate, UV LED technology offers a more sustainable and cost-effective solution. The lower energy consumption of UV LED technology not only reduces operating costs but also contributes to a reduced environmental impact, making it an attractive option for businesses looking to improve their sustainability credentials.

Furthermore, 365 nm UV LED technology has proven to be versatile, with applications across a wide range of industries. In the manufacturing sector, UV LED technology is being used for curing and bonding processes, where its precise and controlled output is essential for achieving high-quality results. In the printing industry, UV LED technology is replacing traditional mercury lamps for curing inks, leading to faster production times and improved print quality. Additionally, UV LED technology is also finding applications in medical and scientific fields, where its ability to sterilize and disinfect surfaces is being harnessed for a variety of purposes.

The potential of 365 nm UV LED technology is also leading to advancements in product development and innovation. Researchers and engineers are exploring new uses for UV LED technology, from compact and portable devices for medical and healthcare applications to integrated solutions for consumer electronics. The ability to harness the power of UV LED technology in such diverse ways is driving forward advancements in a range of industries, with the potential to reshape how we live and work.

As the capabilities of 365 nm UV LED technology continue to expand and evolve, it is clear that this technology is set to play a crucial role in the future of many industries. The reliability, energy efficiency, and versatility of UV LED technology are driving forward advancements in manufacturing, printing, healthcare, and beyond, with the potential to revolutionize processes and products across the board. As businesses and industries increasingly look for more sustainable and effective solutions, it is likely that the demand for 365 nm UV LED technology will continue to grow, unlocking new opportunities and driving innovation for years to come.

Conclusion

In conclusion, the power and potential of 365 nm UV LED technology is truly remarkable. With its numerous applications across various industries such as healthcare, electronics, and printing, it has proven to be a game-changer in terms of efficiency and effectiveness. As a company with 20 years of experience in the industry, we have witnessed firsthand the transformation that this technology has brought about. We are excited to see how 365 nm UV LED technology will continue to revolutionize processes and drive innovation in the years to come. Embracing this technology is not only an investment in the future but a step towards progress and advancement in the global market.