Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

The Advantages Of UV Curing In Industrial Applications

Are you curious about the benefits of UV curing in industrial applications? Look no further! In this article, we will explore the various advantages of using UV curing technology in industrial settings. From faster production times to improved quality and efficiency, UV curing has revolutionized the manufacturing process. Read on to discover how UV curing can enhance your industrial operations and take your business to the next level.

- Understanding UV Curing in Industrial Processes

UV curing has become an integral part of industrial processes, offering a wide range of advantages that make it a preferred method for various applications. At Tianhui, we understand the importance of UV curing in industrial processes and are committed to providing high-quality UV curing solutions to meet the needs of our customers.

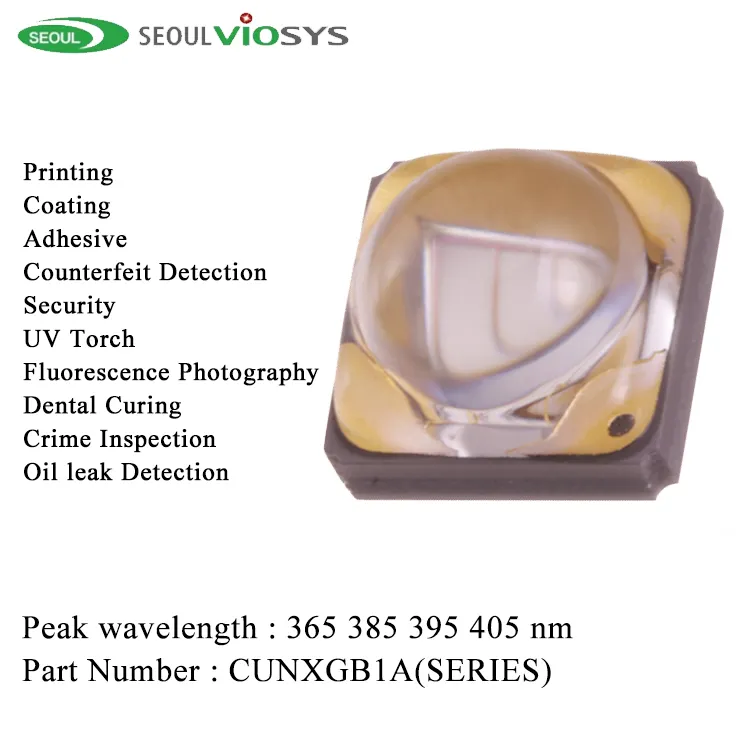

UV curing is a technology that uses ultraviolet light to instantly cure or dry inks, coatings, adhesives, and other materials. This process is commonly used in industries such as printing, automotive, electronics, and medical devices, among others. The use of UV curing offers numerous advantages over traditional curing methods, making it a popular choice for manufacturers looking to improve efficiency and quality in their operations.

One of the key advantages of UV curing in industrial applications is its fast curing time. Unlike traditional curing methods that rely on heat or chemical reactions to dry materials, UV curing achieves instant curing through the use of UV light. This results in significantly reduced production time and increased throughput, leading to improved overall productivity and cost savings for manufacturers. Additionally, the fast curing time of UV curing allows for the production of high-quality, durable products with superior finish and performance.

Another important advantage of UV curing is its environmental benefits. Traditional curing methods often use solvents and emit volatile organic compounds (VOCs) during the curing process, leading to harmful emissions and environmental pollution. In contrast, UV curing is a solvent-free process that does not generate harmful emissions, making it a more environmentally friendly option for manufacturers. This not only helps companies reduce their environmental footprint but also ensures compliance with stringent environmental regulations.

UV curing also offers exceptional versatility and flexibility in industrial applications. The process can be tailored to meet specific curing requirements, allowing manufacturers to achieve precise control over the curing process and desired outcomes. Whether it’s for curing inks on packaging materials, coatings on automotive parts, or adhesives in electronic components, UV curing can be customized to deliver consistent, high-quality results across a wide range of applications.

Furthermore, UV curing provides enhanced durability and resistance properties to the cured materials. The instantaneous nature of UV curing results in a stronger bond and improved material properties, ultimately leading to products that are more durable, scratch-resistant, and capable of withstanding harsh environmental conditions. This makes UV-cured products ideal for applications where longevity and performance are crucial, such as in the automotive and aerospace industries.

In conclusion, the advantages of UV curing in industrial applications are undeniable. At Tianhui, we recognize the significance of UV curing technology and its impact on the manufacturing industry. We are committed to providing innovative and reliable UV curing solutions that empower our customers to achieve greater efficiency, cost savings, and environmental sustainability in their operations. With our expertise and dedication to excellence, we aim to help manufacturers harness the full potential of UV curing to elevate their production processes and deliver superior products to the market.

- Advantages of UV Curing Technology in Industrial Applications

UV curing technology has been making significant strides in industrial applications in recent years, with a growing number of companies recognizing the various benefits it offers. Tianhui, a leader in UV curing technology, has been at the forefront of this innovation, providing cutting-edge solutions for a wide range of industrial processes. In this article, we will explore the many advantages that UV curing technology brings to industrial applications, and why Tianhui is the brand of choice for businesses seeking to harness its power.

One of the key advantages of UV curing technology in industrial applications is its speed and efficiency. Traditional curing methods, such as heat or air drying, can be time-consuming and require a significant amount of energy. In contrast, UV curing offers rapid curing times, allowing for increased productivity and reduced production costs. This is especially beneficial in high-volume manufacturing settings, where time is of the essence. Tianhui's UV curing systems are designed to deliver swift and reliable curing, helping businesses meet their production targets with ease.

Another advantage of UV curing technology is its ability to produce superior quality finishes. The precise control and consistency offered by UV curing result in flawless, uniform coatings that are free from imperfections. This is particularly important in industries such as automotive, aerospace, and electronics, where the aesthetic appeal and durability of the finished product are paramount. Tianhui's UV curing solutions are engineered to deliver impeccable results, ensuring that businesses can achieve the high standards of quality their customers expect.

In addition to speed and quality, UV curing technology also offers environmental benefits. Unlike traditional curing methods that rely on solvents and emit volatile organic compounds (VOCs), UV curing is a solvent-free process that generates minimal emissions. This not only reduces the environmental impact of industrial operations but also creates a safer and healthier working environment for employees. Tianhui is committed to sustainability and offers UV curing systems that are designed to minimize waste and energy consumption, helping businesses operate in an eco-friendly manner.

Furthermore, UV curing technology is versatile and can be applied to a wide range of substrates and materials. Whether it's wood, metal, plastics, or composites, Tianhui's UV curing solutions are capable of delivering exceptional results across various industrial applications. This versatility makes UV curing technology a valuable asset for businesses operating in diverse sectors, empowering them to innovate and explore new opportunities for growth.

In conclusion, the advantages of UV curing technology in industrial applications are undeniable. From its speed and efficiency to its ability to produce high-quality finishes and its environmental benefits, UV curing is revolutionizing the way businesses approach curing processes. Tianhui, with its expertise and dedication to innovation, is the brand of choice for companies looking to harness the power of UV curing technology. With cutting-edge solutions and a commitment to excellence, Tianhui is leading the way in shaping the future of industrial manufacturing.

- Efficiency and Speed: Benefits of UV Curing

Efficiency and Speed: Benefits of UV Curing

Tianhui is proud to offer UV curing technology for industrial applications, providing numerous benefits for businesses seeking to increase efficiency and speed in their manufacturing processes. UV curing technology has revolutionized the way in which industrial products are manufactured, offering a wide range of advantages that make it a valuable investment for companies across various industries.

One of the most significant benefits of UV curing is its unparalleled efficiency. Unlike traditional curing methods that rely on heat and lengthy drying times, UV curing offers a rapid, instantaneous cure that significantly reduces production time. This allows for faster throughput and increased productivity, ultimately leading to cost savings and optimized manufacturing processes. With UV curing, businesses can achieve higher production volumes without sacrificing quality, resulting in a more competitive edge in the market.

In addition to its speed, UV curing also offers superior quality and consistency in the curing process. By utilizing UV light to initiate the curing reaction, manufacturers can ensure a uniform and even cure throughout the product, eliminating issues such as uneven drying and inconsistent results. This level of quality control is essential for industries such as automotive, electronics, and medical devices, where precision and reliability are paramount. With UV curing, businesses can deliver products that meet the highest standards of quality and performance, setting them apart from the competition.

Furthermore, UV curing technology is environmentally friendly, offering a sustainable alternative to solvent-based curing methods. Traditional curing processes often involve the use of volatile organic compounds (VOCs) and other harmful chemicals, posing risks to both the environment and worker safety. In contrast, UV curing does not emit harmful emissions and does not require the use of solvents, making it a cleaner and safer option for industrial applications. By adopting UV curing technology, companies can reduce their environmental footprint and contribute to a more sustainable future.

Another key advantage of UV curing is its versatility and adaptability to a wide range of substrates and materials. Whether it's wood, metal, plastic, or glass, UV curing can effectively cure and bond various types of materials, making it an ideal solution for diverse manufacturing processes. This flexibility allows businesses to streamline their production operations and accommodate different product requirements, ultimately increasing their overall efficiency and capability.

In conclusion, the benefits of UV curing in industrial applications are undeniable. From its speed and efficiency to its quality, sustainability, and versatility, UV curing technology has become a game-changer for manufacturers seeking to enhance their production processes. As a leader in UV curing solutions, Tianhui is committed to helping businesses harness the power of this technology to achieve optimal results in their manufacturing operations. Embracing UV curing is not only a sound investment for businesses but also a step towards a more sustainable and efficient future.

- Cost-Effectiveness and Environmental Benefits of UV Curing

UV curing technology has become a popular method in various industrial applications due to its cost-effectiveness and environmental benefits. Tianhui, a leading player in the UV curing industry, has been at the forefront of promoting the advantages of this technology and its positive impact on industrial processes.

One of the key advantages of UV curing is its cost-effectiveness. Traditional curing methods such as thermal curing or solvent-based curing often require a significant amount of energy and resources, leading to higher operation costs. In contrast, UV curing is a more energy-efficient process, as it uses UV light to instantly cure coatings, inks, adhesives, and other materials. This leads to reduced energy consumption and faster production speeds, ultimately resulting in lower production costs for manufacturers. Tianhui's UV curing systems are designed to optimize efficiency and minimize resource usage, making them a cost-effective solution for industrial applications.

Furthermore, UV curing offers significant environmental benefits compared to traditional curing methods. Conventional curing processes often involve the use of solvents and other harmful chemicals, which can lead to harmful emissions and contribute to air and water pollution. In contrast, UV curing is a solvent-free process that produces minimal volatile organic compounds (VOCs) and hazardous air pollutants (HAPs), making it a cleaner and more environmentally friendly option. Tianhui's UV curing systems are designed to comply with strict environmental regulations and standards, ensuring that their technology contributes to a healthier and more sustainable industrial landscape.

In addition to cost-effectiveness and environmental benefits, UV curing also offers superior performance and versatility in various industrial applications. Tianhui's UV curing systems are capable of curing a wide range of materials, including plastics, glass, metals, and composites, making them suitable for diverse manufacturing processes. The instant curing capabilities of UV technology also result in improved product quality and durability, as well as enhanced production efficiency. With customizable UV curing solutions, Tianhui provides manufacturers with the flexibility to optimize their production processes and achieve the desired results.

Moreover, UV curing technology enables precise and consistent curing, ensuring uniformity and reliability in the final products. This level of control and predictability is essential in industries such as automotive, electronics, and packaging, where the quality and performance of finished products are critical. Tianhui's UV curing systems are designed to meet the stringent demands of these industries, providing manufacturers with the confidence to deliver superior products to their customers.

In conclusion, the advantages of UV curing in industrial applications are undeniable, particularly in terms of cost-effectiveness and environmental benefits. Tianhui's commitment to developing innovative and sustainable UV curing solutions has positioned the company as a trusted partner for manufacturers seeking to enhance their production processes. As industries continue to prioritize efficiency, quality, and sustainability, UV curing technology will undoubtedly play a crucial role in shaping the future of manufacturing.

- Future Outlook: The Potential of UV Curing in Industrial Settings

UV curing has been widely adopted in various industrial applications due to its many advantages, such as high efficiency, cost-effectiveness, and environmental friendliness. As the technology continues to evolve, the future outlook for UV curing in industrial settings looks promising, with the potential to revolutionize the way products are manufactured and processed.

One area where UV curing is poised to make a significant impact is in the field of 3D printing. With the demand for customized and complex products on the rise, 3D printing has become a popular manufacturing method. UV curing technology offers a faster and more precise curing process, allowing for increased production speeds and improved product quality. Tianhui, a leader in UV curing solutions, is at the forefront of developing advanced UV curing systems for 3D printing applications, helping manufacturers stay ahead of the competition.

In the automotive industry, UV curing is already widely used for coating and bonding applications. With ongoing advancements in UV LED technology, the potential for UV curing to further enhance automotive manufacturing processes is substantial. Tianhui's UV curing systems are designed to meet the specific requirements of the automotive industry, providing reliable and energy-efficient solutions for curing adhesives, coatings, and composite materials.

Furthermore, UV curing is making significant strides in the electronics industry, where precision and speed are essential. Tianhui's UV curing systems are designed to deliver consistent and uniform curing results, ensuring the reliability and performance of electronic components. As electronic devices continue to become more compact and sophisticated, the demand for UV curing technology that can accommodate smaller and more intricate assembly processes is expected to grow.

In the packaging and labeling sector, UV curing is becoming increasingly popular for its ability to provide instant curing of inks and coatings, leading to improved productivity and reduced production times. As consumer preferences for sustainable and eco-friendly packaging continue to drive market trends, UV curing offers a greener alternative to traditional solvent-based curing methods. Tianhui's UV LED curing solutions are designed to maximize energy efficiency and minimize environmental impact, making them an ideal choice for sustainable packaging applications.

The future outlook for UV curing in industrial settings also extends to the medical and pharmaceutical industries, where strict regulations and quality standards are paramount. Tianhui's UV curing systems are designed to meet the stringent requirements of these industries, providing reliable and consistent curing for medical devices, pharmaceutical packaging, and diagnostic equipment.

In conclusion, the potential of UV curing in industrial settings is vast and continues to expand as technology advances. Tianhui is committed to driving innovation and pushing the boundaries of UV curing technology, offering tailored solutions to meet the evolving needs of various industries. With its expertise and dedication to excellence, Tianhui is poised to play a key role in shaping the future of UV curing in industrial applications.

Conclusion

In conclusion, the advantages of UV curing in industrial applications are clear and numerous. From increased production speed and efficiency to improved environmental and safety benefits, it's clear why more and more companies are turning to UV curing for their industrial needs. With 20 years of experience in the industry, we've seen firsthand the positive impact that UV curing can have on a wide range of applications. As technology continues to advance, we can only expect to see even more advantages and innovation in the UV curing sector. It's an exciting time to be involved in industrial applications, and we look forward to the future advancements that UV curing will bring.