Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Revolutionizing UV Technology With 365nm UV LED: The Future Of Ultraviolet Light

Are you curious about the latest advancements in UV technology? Look no further, as we dive into the exciting world of 365nm UV LED technology and how it is revolutionizing the future of ultraviolet light. Join us as we explore the potential applications, benefits, and impact of this cutting-edge technology. Whether you're a seasoned expert or simply intrigued by the possibilities, this article is a must-read for anyone interested in the future of UV technology.

- The Advantages of 365nm UV LED Technology

The Advantages of 365nm UV LED Technology

In recent years, there has been significant progress in the development of UV LED technology, particularly in the area of 365nm UV LED. This advancement has revolutionized the way ultraviolet light is utilized, offering a myriad of advantages over traditional UV technologies. In this article, we will explore the benefits and potential applications of 365nm UV LED technology, and its implications for the future of UV light.

One of the key advantages of 365nm UV LED technology is its efficiency. Compared to traditional UV lamps, 365nm UV LED lights consume significantly less energy, making them more cost-effective and environmentally friendly. This increased efficiency also translates to lower operating costs and reduced maintenance, as 365nm UV LED lights have a longer lifespan and require less frequent replacement.

Furthermore, 365nm UV LED technology offers precise control and consistent output. This enables more accurate and targeted UV exposure, which is particularly advantageous in industries such as healthcare, where precise UV dosing is essential for disinfection and sterilization processes. The ability to deliver consistent UV output is also critical in manufacturing and printing applications, where uniform curing and printing quality are paramount.

In addition to efficiency and precision, 365nm UV LED technology also boasts a wider range of applications. The narrow bandwidth of 365nm UV light is well-suited for a variety of purposes, including UV curing, printing, and medical treatments. Furthermore, the compact size and flexibility of UV LED fixtures enable their integration into a wider range of systems and equipment, making them ideal for diverse applications across different industries.

The use of 365nm UV LED technology also brings about important safety benefits. Unlike traditional UV lamps, which contain toxic mercury, 365nm UV LED lights are mercury-free and pose no risk of environmental contamination or human exposure to harmful substances. This makes them a safer and more sustainable option for UV light applications, aligning with the growing demand for greener and cleaner technologies.

Moreover, 365nm UV LED technology offers enhanced compatibility with heat-sensitive materials. The low heat output of UV LED lights minimizes the risk of damage to delicate substrates, enabling the use of UV curing in a wider range of applications, including the printing and electronics industries. This capability opens up new possibilities for the integration of UV technology in manufacturing processes, expanding its potential impact on various industries.

In conclusion, 365nm UV LED technology represents a significant advancement in the field of UV light. With its advantages in efficiency, precision, versatility, safety, and compatibility, 365nm UV LED technology is poised to revolutionize the way ultraviolet light is utilized across different industries. The future of UV technology lies in the widespread adoption of 365nm UV LED, offering unprecedented opportunities for innovation and growth in UV light applications.

- Applications of 365nm UV LED in Various Industries

The use of ultraviolet (UV) light has been an integral part of various industries for many years. From sterilization and disinfection to curing and printing, the applications of UV light are vast and diverse. Traditionally, UV lamps have been the primary source of UV light, but the introduction of 365nm UV LED technology has revolutionized the way UV light is utilized in various industries.

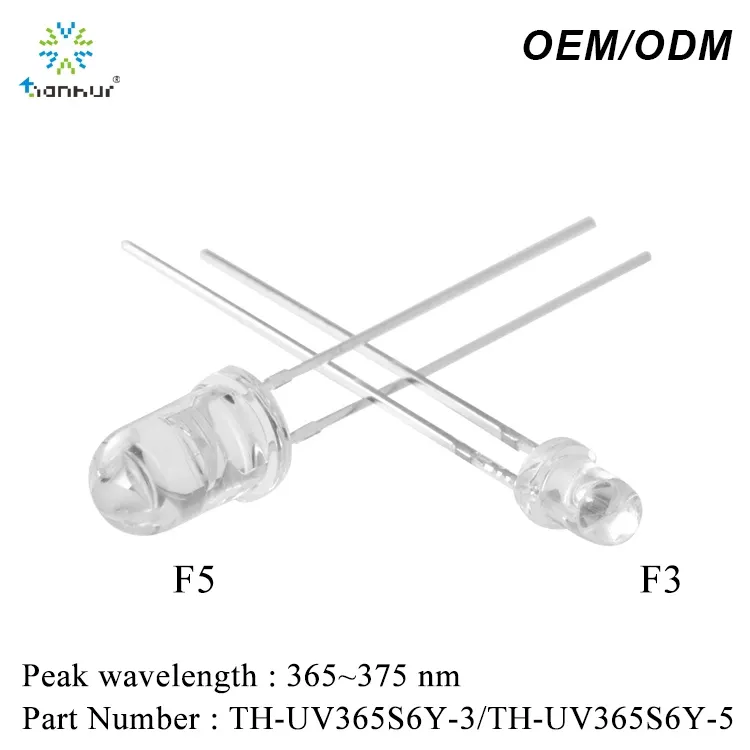

At the forefront of this revolution is the 365nm UV LED, a technology that offers several advantages over traditional UV lamps. With its narrow band wavelength of 365nm, UV LED provides more specific and targeted UV light, making it highly effective for various applications. Its small size, low power consumption, and long lifespan further contribute to its appeal in different industries.

One of the key applications of 365nm UV LED is in the field of sterilization and disinfection. The 365nm wavelength has been found to be highly effective in killing bacteria, viruses, and other harmful microorganisms. This makes UV LED an ideal solution for water and air purification systems, as well as surface sterilization in healthcare facilities, laboratories, and food processing plants. The use of 365nm UV LED for sterilization purposes not only ensures effective disinfection but also provides a more energy-efficient and environmentally friendly alternative to traditional methods.

In the manufacturing industry, 365nm UV LED is making significant strides in the field of curing and printing. UV-curable inks and coatings are widely used for printing and coating applications in various industries, including packaging, signage, and electronics. The use of 365nm UV LED for curing offers faster curing times, improved adhesion, and reduced energy consumption compared to traditional UV curing systems. This not only enhances the efficiency of the manufacturing process but also reduces the overall environmental impact.

Furthermore, 365nm UV LED also finds applications in the field of fluorescence and phosphorescence excitation. The specific wavelength of 365nm is ideal for exciting fluorescent and phosphorescent materials, making UV LED a valuable tool in analytical and scientific research. From fluorescence microscopy to chemical analysis, 365nm UV LED enables precise and controlled excitation of materials, leading to more accurate and reliable results in research and development.

The versatility of 365nm UV LED extends to the field of counterfeit detection and authentication. The precise wavelength of UV LED is crucial in revealing hidden security features in documents, currency, and other valuable items. The use of 365nm UV LED in counterfeit detection ensures a higher level of security and authenticity verification, providing businesses and organizations with an effective tool to combat counterfeiting and fraud.

In conclusion, the emergence of 365nm UV LED technology has paved the way for significant advancements in various industries. Its specific wavelength, energy efficiency, and versatility make it an invaluable tool for sterilization, curing, fluorescence excitation, and counterfeit detection. As the demand for more effective and sustainable UV solutions continues to grow, 365nm UV LED is poised to play a central role in shaping the future of ultraviolet light technology.

- Future Developments in 365nm UV LED Technology

Ultraviolet (UV) technology has seen incredible advancements in recent years, particularly with the introduction of 365nm UV LED technology. This cutting-edge technology has the potential to revolutionize various industries and applications, from curing adhesives and coatings to disinfection and counterfeit detection. In this article, we will explore the future developments in 365nm UV LED technology and its impact on the future of ultraviolet light.

First and foremost, it's crucial to understand the significance of the 365nm wavelength in UV LED technology. Unlike traditional UV lamps, which emit a broad spectrum of UV light, 365nm UV LEDs produce a narrow band of UV light at a specific wavelength. This precise wavelength is particularly effective for curing UV-sensitive materials, as it provides optimal energy output for initiating the curing process. As a result, 365nm UV LED technology offers faster curing times, improved efficiency, and higher quality finishes compared to traditional UV lamps.

One of the most exciting developments in 365nm UV LED technology is its potential for disinfection applications. The COVID-19 pandemic has heightened the demand for effective and efficient disinfection methods, and 365nm UV LEDs have emerged as a promising solution. Research has shown that 365nm UV light is highly effective at deactivating a wide range of pathogens, including bacteria, viruses, and fungi. As a result, 365nm UV LED technology has the potential to revolutionize disinfection practices in healthcare facilities, public spaces, and even personal devices.

In addition to disinfection, 365nm UV LED technology is poised to transform the way we approach counterfeit detection. The precise wavelength of 365nm UV light allows for enhanced detection of security features and markings that are often invisible to the naked eye. This makes 365nm UV LEDs an invaluable tool for verifying the authenticity of banknotes, identification documents, and high-value goods. As counterfeiters become increasingly sophisticated, the advancements in 365nm UV LED technology will play a crucial role in safeguarding against counterfeit products and fraudulent activities.

Furthermore, the future of 365nm UV LED technology holds promise for the development of greener and more sustainable practices. Compared to traditional UV lamps, 365nm UV LEDs consume less energy, have a longer lifespan, and produce minimal heat. This results in reduced energy consumption, lower operating costs, and a smaller carbon footprint. As sustainability becomes a top priority for businesses and industries, the adoption of 365nm UV LED technology will contribute to more eco-friendly manufacturing and production processes.

In conclusion, the future developments in 365nm UV LED technology are poised to revolutionize the way we harness the power of ultraviolet light. From curing and disinfection to counterfeit detection and sustainability, 365nm UV LED technology offers unprecedented opportunities for innovation and advancement. As research and development in this field continue to progress, we can expect to see further breakthroughs that will shape the future of ultraviolet light and its applications in various industries.

- Environmental Impact and Energy Efficiency of 365nm UV LED

The use of ultraviolet (UV) technology has become increasingly popular in various industries, including disinfection, curing, and various medical and scientific applications. With the development of 365nm UV LED technology, there has been a significant revolution in the way UV light is used. This article will delve into the environmental impact and energy efficiency of 365nm UV LED, and how it is shaping the future of ultraviolet light technology.

One of the key advantages of 365nm UV LED technology is its environmental impact. Traditional UV lamps often contain harmful materials such as mercury, which can have detrimental effects on the environment if not disposed of properly. In contrast, 365nm UV LED lamps do not contain any hazardous materials, making them much more environmentally friendly. This not only reduces the potential for environmental pollution but also minimizes the risks associated with handling and disposing of traditional UV lamps. Furthermore, 365nm UV LED technology has a longer lifespan compared to traditional UV lamps, reducing the frequency of disposal and replacement, thus further reducing environmental impact.

In addition to its environmental benefits, 365nm UV LED technology is also significantly more energy efficient. Traditional UV lamps require a substantial amount of energy to operate, making them costly to run and maintain. In contrast, 365nm UV LED lamps consume much less energy, resulting in lower operating costs and reduced energy consumption. This makes 365nm UV LED technology a more sustainable and cost-effective option for businesses and industries that rely on UV technology for their operations.

The energy efficiency of 365nm UV LED technology also has a positive impact on overall carbon footprint and sustainability. By reducing energy consumption, businesses and industries can decrease their greenhouse gas emissions and contribute to overall efforts in reducing carbon footprint. This is particularly important in an era where sustainability and environmental responsibility are at the forefront of many organizations' priorities.

Furthermore, the energy efficiency of 365nm UV LED technology also translates to reduced operating costs for businesses and industries. With lower energy consumption, businesses can save on utility bills, ultimately leading to cost savings in the long run. This makes 365nm UV LED technology not only an environmentally friendly option but also a financially savvy investment for companies looking to upgrade their UV technology.

Overall, the development of 365nm UV LED technology has paved the way for a more environmentally friendly and energy-efficient approach to utilizing UV light. With its reduced environmental impact, lower energy consumption, and cost savings, it is clear that 365nm UV LED technology is revolutionizing the future of ultraviolet light technology. As more industries and businesses embrace this innovative technology, we can expect to see a significant shift towards a more sustainable and efficient use of UV light in various applications.

- The Potential for 365nm UV LED to Replace Traditional UV Light Sources

Revolutionizing UV Technology with 365nm UV LED: The Potential for 365nm UV LED to Replace Traditional UV Light Sources

In recent years, there has been a significant shift in ultraviolet (UV) technology with the emergence of 365nm UV LED. These new LED lights have the potential to completely revolutionize the way we approach UV applications, and they may even replace traditional UV light sources in the near future. This article will explore the capabilities of 365nm UV LED and the potential impact it could have on various industries.

First and foremost, it’s important to understand why 365nm UV LED is garnering so much attention. Traditional UV light sources, such as mercury lamps, have long been the standard for UV applications. However, these sources have several limitations, including their large size, high power consumption, and short lifespan. In contrast, 365nm UV LED offers a compact and energy-efficient alternative with a significantly longer lifespan. This alone makes it an attractive option for many industries.

One of the most promising aspects of 365nm UV LED is its ability to deliver a more targeted and efficient UV light. Traditional UV light sources emit a broad spectrum of light, which can result in unnecessary exposure to harmful UV radiation. In contrast, 365nm UV LED emits a narrow band of UV light at a specific wavelength, making it more precise and effective for various applications, including disinfection, curing, and inspection.

In the field of disinfection, 365nm UV LED has the potential to provide a safer and more effective method for killing bacteria and viruses. With its precise wavelength, it can target microbial DNA and RNA, effectively neutralizing pathogens without the need for harsh chemicals. This has significant implications for healthcare facilities, food processing plants, and public spaces where the need for reliable disinfection is paramount.

Furthermore, 365nm UV LED is proving to be a game changer in the UV curing process. UV curing is used in a wide range of industries, including printing, coatings, and electronics, to quickly and efficiently cure adhesives, inks, and coatings. By utilizing 365nm UV LED, manufacturers can achieve faster curing times, reduced energy consumption, and improved production efficiency, ultimately leading to cost savings and higher quality products.

The use of 365nm UV LED is also advancing UV inspection capabilities in various industries. Its precise wavelength and impressive optical power make it an ideal solution for non-destructive testing, fluorescence detection, and forensic analysis. With its ability to emit UV light in a controlled manner, 365nm UV LED enables more accurate and reliable inspection processes, leading to improved product quality and safety.

In conclusion, the potential of 365nm UV LED to replace traditional UV light sources is undeniable. Its compact size, energy efficiency, and precise UV emission make it a versatile and attractive option for a wide range of applications. As technology continues to advance and the demand for more sustainable and effective UV solutions grows, it is likely that 365nm UV LED will play a pivotal role in shaping the future of UV technology. Industries that adopt this innovative light source will undoubtedly reap the benefits of improved performance, cost savings, and increased sustainability.

Conclusion

In conclusion, the future of ultraviolet light technology is looking brighter than ever with the introduction of 365nm UV LED. As a company with 20 years of experience in the industry, we are excited to be at the forefront of this revolution in UV technology. With the potential to revolutionize various industries, from healthcare to manufacturing, the 365nm UV LED is set to offer a wide range of benefits including increased efficiency, reduced energy consumption, and improved safety. We look forward to seeing how this technology continues to evolve and shape the future of ultraviolet light. Stay tuned for more updates as we continue to lead the way in this exciting new era of UV technology.