Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

How to Light Up the Light Diode

2022-11-20

Tianhui

168

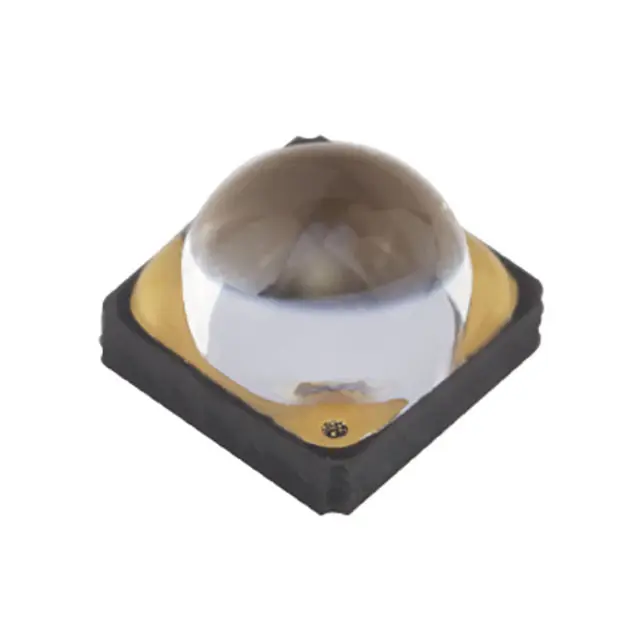

How much do you know about glowing diodes? Today's light -emitting diode market demand is wide. Those who are used in street lights, medical devices, car lights, cameras, power indicator lights and other fields are all involved. Today, the editor mainly wants to explain how to light up the light -emitting diodes. Take the indicator light as an example; when our luminous diode is connected to AC 220V, it is used as a power indicator, and the simplest way is to connect a current -limiting resistor. According to the type of light emitting diodes the size of. The general light-emitting diode is 2.8-3.4V, the materials for various colors are different, and the voltage is different. Now the high brightness light emitting tube, the current 10mA is already bright enough. For general light emitting diode, the working current value is 1mA-15mA. The specific brightness can be changed by adjusting the size of the current limit resistance. The main principle of light emitting diode is actually to form a certain potential barrier through the end voltage of the PN knot. When the position of the positive bias voltage decreases, most of the carrier in the P area and the N area spread to the other party. Because the electronic migration rate is much greater than the air acupoint migration rate, a large number of electronic spreads to the P area, forming an injection of a minority carrier of the P area. These electrons are compounded from the cave on the price, and the energy obtained during composite is released in the form of light energy. This is the principle of PN knot glow. The above is some of the lighting explanations about the light emitting diode today, which is summarized by the editor. If you want to know more information about the light -emitting diode or buy a product, you can directly contact the online customer service, or dial the contact phone for consultation.

Author: Tianhui-Air Disinfection

Author: Tianhui-UV Led manufacturers

Author: Tianhui-UV water disinfection

Author: Tianhui-UV LED Solution

Author: Tianhui-UV Led diode

Author: Tianhui-UV Led diodes manufacturers

Author: Tianhui-UV Led module

Author: Tianhui-UV LED Printing System

Author: Tianhui-UV LED mosquito trap

GET IN TOUCH WITH Us

recommended articles

UltraViolet (UV) LED chips, created by expert manufacturers, hold big promise. In this detailed guide, the focus is on the intricacies of UV LED chips, their making, and how they are evolving. The spotlight is also on the impactful role of key manufacturers in advancing this cutting-edge technology.

In the food and beverage industry, ultraviolet (UV) disinfection technology is a rapidly expanding sector. UV radiation is used to disinfect water, air, and surfaces by killing bacteria, viruses, and other pathogens to make the food healthy. This technology has grown in popularity due to its efficiency, usability, and minimal cost.

Various water treatment technologies including UV water disinfection have been developed in response to the rising demand for pure drinking water. In recent years, Ultraviolet-C (UV-C) LED technology has garnered significant interest for its potential applications in potable water treatment. This technology has a number of advantages over conventional mercury-based UV lamps, including energy efficiency, lower operating costs, and a smaller environmental footprint.

Ultraviolet (UV) disinfection/water purification technology uses UV light to kill harmful microorganisms in water. It's a natural and effective way to purify water without adding chemicals, making it a popular choice for many households and industries. The process works by exposing water to a strong UV light source, which damages the DNA of bacteria, viruses, and other pathogens, causing them to die.

UVC LED technology has gained significant attention in recent years, and it's no surprise that the market is expanding with more home appliances and consumer products adopting the technology. The COVID-19 pandemic only fueled the demand for UVC LED products as consumers and businesses seeked effective ways to disinfect their environments. UVC LEDs offer a safe, reliable, and efficient way to kill bacteria and viruses, making them a popular choice for various applications.

no data

Contact Us

You can find us here

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service

We use cookies to ensure that we give you the best experience on and off our website. please review our privacy policy

Reject

Cookie Settings

Agree Now

Your basic information, online operation behaviors, transaction information, access data are necessary to offer you our normal purchase, transaction, and delivery services. Withdrawal of this authorization will result in the failure of shopping or even paralysis of your account.

Your basic information, online operation behaviors, transaction information, access data are of great significance to improve website construction and enhance your purchase experience.

Your basic information, online operation behaviors, transaction information, preference data, interaction data, forecasting data, and access data will be used for advertising purposes by recommending products more suitable for you.

These cookies tell us how you use the site and help us to make it better. For example, these cookies allow us to count the number of visitors to our website and know how visitors move around when using it. This helps us to improve how our site works. For example, by ensuring that users find what they are looking for and that the loading time of each page is not too long.