Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Exploring The Uses And Benefits Of LED UV 405nm Technology

Are you curious about the potential applications of LED UV 405nm technology? Look no further! In this article, we will explore the uses and numerous benefits of this groundbreaking technology. From its applications in medical devices to its impact on the manufacturing industry, we will delve into the ways in which LED UV 405nm technology is revolutionizing various sectors. Join us as we uncover the endless possibilities and advantages of this cutting-edge technology.

Understanding the Basics of LED UV 405nm Technology

As technology continues to advance, new innovations in the field of LED UV 405nm technology have been developed, revolutionizing various industries and processes. In this article, we will delve into the uses and benefits of this cutting-edge technology, while also gaining a comprehensive understanding of its basics.

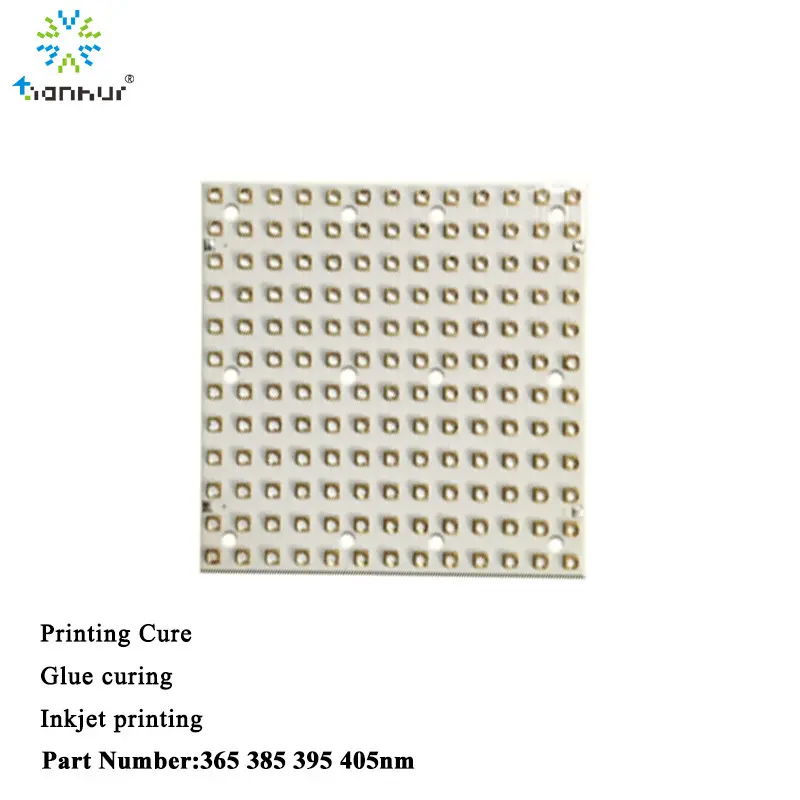

LED UV 405nm technology refers to the use of light-emitting diodes (LEDs) that emit ultraviolet (UV) light at a wavelength of 405nm. This specific wavelength is known for its ability to effectively cure and polymerize various materials, making it a versatile tool in numerous applications.

One of the primary uses of LED UV 405nm technology is in the realm of 3D printing. With its precise and controlled curing capabilities, this technology enables the rapid and efficient curing of photopolymer resins used in stereolithography (SLA) and digital light processing (DLP) 3D printers. This results in the production of high-quality, durable 3D-printed objects with intricate details and smooth surfaces.

Furthermore, LED UV 405nm technology is widely employed in the field of coatings and adhesives. The UV light emitted at this wavelength initiates the curing process of UV-curable coatings and adhesives, leading to quick-drying, durable finishes. This is particularly advantageous in industries such as automotive, electronics, and construction, where fast production and assembly processes are crucial.

In addition to its use in 3D printing and coatings, LED UV 405nm technology is also utilized in the medical and dental fields. It plays a vital role in the curing of dental composites and restorative materials, ensuring the longevity and strength of dental restorations. Moreover, it is instrumental in the sterilization of medical instruments and equipment, as UV light at 405nm is effective in killing bacteria and viruses.

The benefits of LED UV 405nm technology are numerous and far-reaching. Its energy-efficient nature and long lifespan result in cost savings and reduced environmental impact. Additionally, its instant on/off capabilities and precise control of curing processes contribute to enhanced productivity and consistency in manufacturing operations. Furthermore, the use of UV light at 405nm wavelength minimizes heat generation, thereby preventing damage to sensitive materials and substrates.

It is important to note that proper understanding and implementation of LED UV 405nm technology are crucial for achieving optimal results. Factors such as exposure time, light intensity, and material compatibility must be carefully considered to ensure the successful curing and polymerization of UV-sensitive materials.

In conclusion, LED UV 405nm technology has emerged as a game-changing innovation with diverse applications and significant advantages. From 3D printing to coatings, and from medical sterilization to dental restorations, its impact continues to be felt across various industries. As this technology continues to evolve, its potential for further advancements and breakthroughs remains promising.

Benefits of Using LED UV 405nm Technology in Various Industries

LED UV 405nm technology is revolutionizing various industries with its numerous benefits and uses. From healthcare to manufacturing, this advanced technology is making waves and transforming the way businesses operate. In this article, we will explore the many benefits of using LED UV 405nm technology in various industries and how it is changing the game for businesses worldwide.

In the healthcare industry, LED UV 405nm technology is being used for disinfection purposes. Its ability to kill bacteria, viruses, and other harmful microorganisms makes it a valuable tool in healthcare facilities. Hospitals are utilizing this technology to disinfect medical equipment, surfaces, and even air, in order to create a safer and cleaner environment for patients and staff. This has proven to be crucial in preventing the spread of infections and diseases, ultimately saving lives and reducing healthcare costs.

In the manufacturing industry, LED UV 405nm technology is being used for curing adhesives, coatings, and inks. Its ability to provide instant curing and reduce production time has revolutionized the manufacturing process. This technology has also proven to be more energy-efficient and cost-effective compared to traditional curing methods, making it a preferred choice for many manufacturers.

Additionally, LED UV 405nm technology is also being used in the printing industry. Its ability to produce high-quality prints in a shorter amount of time has made it a game-changer for businesses in this sector. The precision and speed of LED UV 405nm technology have allowed businesses to meet tight deadlines and produce prints with superior quality, ultimately leading to higher customer satisfaction and increased profits.

Furthermore, LED UV 405nm technology has also found its way into the food and beverage industry. Its ability to extend the shelf life of food products by inhibiting the growth of bacteria and mold has been a game-changer for businesses in this sector. This technology has also been used for sterilizing food packaging and equipment, ensuring the safety and quality of food products.

In the automotive industry, LED UV 405nm technology is being used for adhesive bonding and curing. Its ability to provide instant curing and high bond strength has made it an essential tool in the production of automobiles. This technology has proven to be more reliable and efficient compared to traditional curing methods, ultimately improving the quality and durability of automotive products.

While LED UV 405nm technology has already made a significant impact in various industries, its potential for growth and innovation is limitless. As businesses continue to explore and harness the benefits of this advanced technology, the possibilities for its uses are endless. From healthcare to manufacturing, the impact of LED UV 405nm technology is undeniable, and its future looks bright.

Applications of LED UV 405nm Technology in Medical and Scientific Fields

LED UV 405nm technology has found a wide range of applications in both the medical and scientific fields, revolutionizing the way various processes are carried out. This technology has proven to be highly beneficial, offering a multitude of advantages over traditional methods. In this article, we will explore the diverse uses and benefits of LED UV 405nm technology in these crucial sectors.

In the medical field, LED UV 405nm technology has played a crucial role in sterilization and disinfection processes. The 405nm wavelength has been found to be highly effective in killing a wide range of pathogens, including bacteria, viruses, and fungi. This has led to its widespread use in disinfecting medical equipment, surfaces, and even air in healthcare facilities. The use of LED UV 405nm technology has proven to be instrumental in reducing the risk of healthcare-associated infections, ultimately leading to improved patient outcomes.

Furthermore, LED UV 405nm technology has also been employed in phototherapy treatments for various skin conditions. The 405nm wavelength has been found to be effective in targeting and treating conditions such as psoriasis, eczema, and acne. This non-invasive treatment approach has gained popularity due to its minimal side effects and high efficacy, offering patients a more comfortable and efficient treatment option.

In the scientific field, LED UV 405nm technology has opened up new possibilities in research and experimentation. The precise and controlled nature of this technology has made it invaluable in various scientific processes, including fluorescence microscopy, flow cytometry, and DNA analysis. The 405nm wavelength is particularly useful for exciting fluorescent dyes and proteins, allowing researchers to visualize and study biological processes with exceptional clarity and accuracy.

Additionally, LED UV 405nm technology has also been employed in the field of bioimaging, where it is used to illuminate and capture images of cellular and molecular structures. This has significantly contributed to advancements in understanding and studying the complexities of biological systems, ultimately leading to breakthroughs in various areas of scientific research.

The benefits of LED UV 405nm technology in both the medical and scientific fields are undeniable. Its non-thermal nature and precise targeting capabilities make it a safe and efficient tool for a wide range of applications. Furthermore, the energy-efficient and long-lasting nature of LED UV 405nm technology makes it a cost-effective solution for medical and scientific institutions, ultimately contributing to increased productivity and reduced operational costs.

In conclusion, the applications of LED UV 405nm technology in the medical and scientific fields have revolutionized various processes and procedures, offering numerous benefits and advantages over traditional methods. As technology continues to advance, the potential for further utilization and innovation in these sectors is limitless, ultimately leading to improved outcomes and a deeper understanding of the complexities of the human body and the natural world.

Environmental Impact of LED UV 405nm Technology

LED UV 405nm technology has made significant strides in recent years and is being widely used across various industries. This technology has not only revolutionized processes and production methods but has also had a positive impact on the environment. In this article, we will explore the environmental impact of LED UV 405nm technology and its uses and benefits.

LED UV 405nm technology refers to the use of light-emitting diodes (LEDs) that emit ultraviolet (UV) light at a wavelength of 405 nanometers. This technology has been widely adopted in industries such as printing, manufacturing, and healthcare, among others. The use of LED UV 405nm technology has several environmental benefits, primarily due to its energy efficiency and reduced environmental footprint.

One of the key environmental benefits of LED UV 405nm technology is its energy efficiency. Traditional UV curing systems use mercury vapor lamps, which consume a significant amount of energy and have a relatively short lifespan. In contrast, LED UV 405nm technology has a much longer lifespan and consumes up to 70% less energy than traditional UV curing systems. This reduction in energy consumption translates to lower carbon emissions and a smaller environmental impact.

Furthermore, LED UV 405nm technology does not emit harmful ozone or produce hazardous waste, making it a more sustainable and environmentally friendly option. Traditional UV curing systems generate ozone as a byproduct, which is harmful to the environment and human health. In contrast, LED UV 405nm technology produces no ozone, reducing air pollution and contributing to a healthier work environment.

Another environmental benefit of LED UV 405nm technology is its reduced greenhouse gas emissions. The energy efficiency of LED UV 405nm technology means lower energy consumption, which in turn reduces the demand for fossil fuels and decreases greenhouse gas emissions. This makes LED UV 405nm technology a more sustainable option for industries looking to reduce their environmental impact.

In addition to its environmental benefits, LED UV 405nm technology also offers several practical advantages. It provides instant curing, leading to faster production times and increased productivity. Additionally, LED UV 405nm technology enables the use of a wider range of substrates and coatings, making it a versatile solution for various applications.

In conclusion, LED UV 405nm technology offers a range of environmental benefits, including energy efficiency, reduced greenhouse gas emissions, and a smaller environmental footprint. Its practical advantages and versatility make it an attractive option for industries seeking to improve their environmental performance while maintaining high levels of productivity. As the demand for sustainable technologies continues to grow, LED UV 405nm technology is poised to play a key role in shaping a more environmentally conscious future.

Future Developments and Innovations in LED UV 405nm Technology

LED UV 405nm technology has been a game-changer in various industries, and its future developments and innovations continue to shape its uses and benefits. In this article, we will explore the various applications and advantages of LED UV 405nm technology, as well as the potential developments and innovations on the horizon.

LED UV 405nm technology has revolutionized the printing industry, offering faster curing times, reduced energy consumption, and increased durability compared to traditional UV curing methods. The precise wavelength of 405nm allows for efficient curing of UV inks and coatings, resulting in high-quality, vibrant prints with minimal heat generation.

Another significant application of LED UV 405nm technology is in the medical field, where it is used for sterilization and disinfection purposes. The 405nm wavelength effectively eliminates bacteria, viruses, and other pathogens, making it a valuable tool in maintaining a clean and sterile environment in healthcare facilities.

In the manufacturing sector, LED UV 405nm technology has been adopted for adhesive curing, bonding, and sealing processes. Its quick curing capabilities and ability to bond various materials make it an ideal solution for assembly line production, contributing to increased efficiency and productivity.

As the demand for environmentally friendly and energy-efficient technologies continues to grow, LED UV 405nm technology has emerged as a sustainable alternative to traditional curing methods. Its low energy consumption, long-lasting UV LED lamps, and reduced use of harmful chemicals make it an environmentally conscious choice for businesses and industries.

Looking ahead, future developments and innovations in LED UV 405nm technology are poised to further enhance its uses and benefits. One area of potential advancement is in the development of more efficient and cost-effective UV LED lamps. Researchers and manufacturers are working on increasing the longevity and stability of UV LED lamps, as well as exploring new materials and designs to improve overall performance.

Additionally, advancements in UV 405nm curing equipment are focusing on improving the precision and control of curing processes. This includes the development of more advanced cooling systems and optics to ensure consistent and uniform curing across different substrates and applications.

The potential for integrating LED UV 405nm technology into new industries and applications is also an area of continuous exploration and innovation. From food packaging and consumer electronics to automotive and aerospace, the versatility of LED UV 405nm technology offers opportunities for expansion into a wide range of sectors.

In conclusion, LED UV 405nm technology has proven to be a versatile and valuable tool across various industries, offering numerous benefits in terms of efficiency, sustainability, and performance. As ongoing developments and innovations continue to shape the future of this technology, the potential for even greater uses and advantages is promising. Witnessing the evolution and expansion of LED UV 405nm technology will undoubtedly lead to further advancements and opportunities for businesses and industries to explore.

Conclusion

In conclusion, the exploration of LED UV 405nm technology has opened up a world of possibilities and benefits in various industries. Its uses in curing, disinfection, and other applications have proven to be efficient, cost-effective, and environmentally friendly. With 20 years of experience in the industry, our company is excited to continue exploring and utilizing this cutting-edge technology to meet the evolving needs of our customers. We look forward to the continued advancement and application of LED UV 405nm technology in the years to come.