Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Exploring The Potential Of 385nm UV LED Technology

Welcome to our exploration of the promising potential of 385nm UV LED technology. In this article, we delve into the exciting advancements and applications of this cutting-edge technology, shedding light on its benefits and possibilities. Join us as we uncover the groundbreaking innovations and opportunities that 385nm UV LED technology offers, and discover why it is rapidly becoming a game-changer in various industries. Whether you're a tech enthusiast, a researcher, or simply curious about the latest developments in UV LED technology, this article is sure to pique your interest and expand your understanding of this fascinating field.

Understanding the Basics of 385nm UV LED Technology

UV LED technology has made significant advancements in recent years, providing a wide range of applications across various industries. One specific area of interest is the 385nm UV LED technology, which has shown great potential for a multitude of uses. In this article, we will explore the basics of 385nm UV LED technology and its potential impacts on different sectors.

UV LED technology operates within the ultraviolet spectrum, emitting light at a wavelength of 385nm. This specific wavelength falls within the UVA range, known for its ability to induce fluorescence in certain materials and to initiate photochemical reactions. This makes 385nm UV LED technology a valuable tool in industries such as manufacturing, healthcare, and research.

In manufacturing, 385nm UV LED technology is utilized for curing adhesives, coatings, and inks. The high-energy output of 385nm UV light triggers the polymerization process, causing these materials to harden and become more durable. This process is more efficient and environmentally friendly compared to traditional methods, as it does not produce harmful by-products or require high temperatures. As a result, manufacturers can improve their production processes while reducing their environmental impact.

In the healthcare sector, 385nm UV LED technology is used for sterilization and disinfection purposes. The germicidal properties of UVA light make it effective at killing bacteria, viruses, and other microorganisms. By harnessing 385nm UV LED technology, healthcare facilities can ensure a higher level of cleanliness and reduce the risk of infections spreading. Additionally, this technology can be integrated into medical devices and equipment, further enhancing their safety and functionality.

Research and development also benefit from 385nm UV LED technology, particularly in the fields of chemistry and material science. The unique properties of UVA light enable researchers to study the behavior of various compounds and materials, as well as to initiate specific chemical reactions. This contributes to the advancement of new materials, processes, and technologies, ultimately driving innovation and progress in diverse scientific disciplines.

Furthermore, 385nm UV LED technology has the potential to impact other industries such as agriculture, forensic science, and entertainment. In agriculture, it can be used for pest control and crop enhancement, while in forensic science, it can aid in the detection of trace evidence and biological fluids. In the entertainment industry, the fluorescence-inducing properties of 385nm UV LED technology have applications in visual effects and artistic displays.

Overall, the understanding of the basics of 385nm UV LED technology is crucial for realizing its full potential across various sectors. As this technology continues to evolve and become more accessible, its impact on industries and society as a whole is expected to expand. By leveraging the unique capabilities of 385nm UV LED technology, businesses and researchers can achieve new levels of efficiency, safety, and innovation, paving the way for a brighter future.

Applications and Limitations of 385nm UV LED Technology

UV LED technology has been a game-changer in various industries, offering a wide range of applications and benefits. In recent years, 385nm UV LED technology has gained significant attention due to its unique properties and potential. This article aims to explore the applications and limitations of 385nm UV LED technology, shedding light on its capabilities and areas where improvements are needed.

One of the key applications of 385nm UV LED technology is in the field of sterilization and disinfection. The 385nm wavelength is particularly effective in deactivating bacteria, viruses, and other microorganisms, making it an ideal choice for medical and healthcare facilities, water treatment plants, and food processing industries. The ability of 385nm UV LED technology to eliminate harmful pathogens without the use of chemicals makes it a sustainable and eco-friendly solution for maintaining hygienic environments.

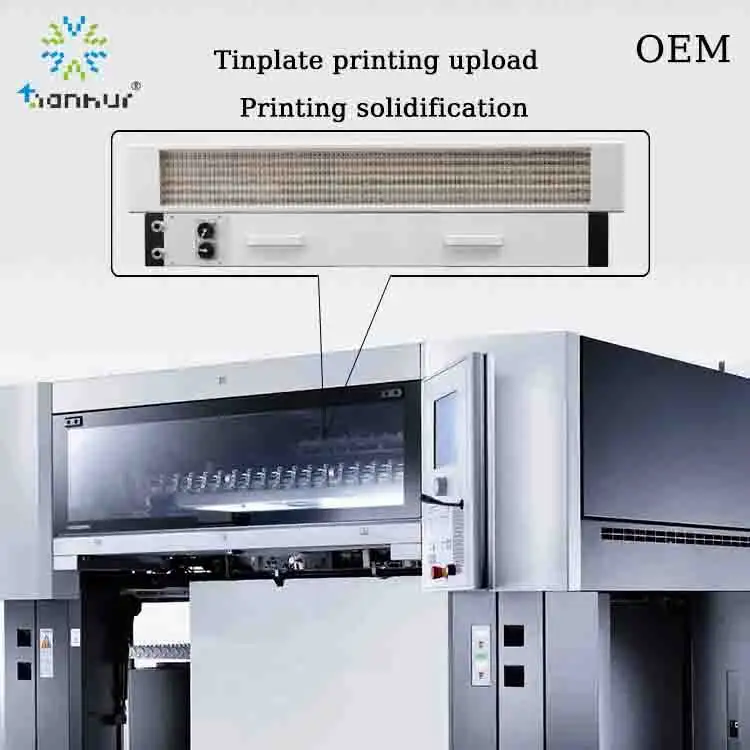

Furthermore, 385nm UV LED technology has found its place in the field of industrial printing and curing. The high-energy output of 385nm UV LEDs enables rapid curing of inks, coatings, and adhesives, leading to increased production efficiency and reduced energy consumption. This technology has revolutionized the printing and packaging industry by offering precise and controlled curing processes, which are essential for achieving high-quality results.

In the field of counterfeit detection and security, 385nm UV LED technology plays a crucial role. Its ability to reveal hidden markings, watermarks, and special security features makes it an invaluable tool for authentication and verification purposes. This is especially important in industries such as banking, government documents, and brand protection, where the detection of counterfeit products is a constant challenge.

Despite its promising applications, 385nm UV LED technology also presents certain limitations that need to be addressed. One of the major challenges is the limited range of materials that can effectively utilize the 385nm wavelength for curing and bonding processes. As a result, further research and development efforts are required to optimize the compatibility of 385nm UV LED technology with a wider range of substrates and applications.

Another limitation is the potential health risks associated with prolonged exposure to 385nm UV radiation. Safety measures and protective equipment are necessary when working with 385nm UV LED systems to minimize the risk of skin and eye exposure. Additionally, proper maintenance and calibration of UV LED equipment are essential to ensure consistent and reliable performance while safeguarding the health and safety of operators.

In conclusion, 385nm UV LED technology offers a plethora of applications across various industries, ranging from sterilization and curing to counterfeit detection and security. However, it is important to acknowledge the existing limitations and challenges associated with this technology, emphasizing the need for ongoing research and development to further enhance its capabilities and safety. As technology continues to advance, 385nm UV LED technology holds great potential for addressing current and future demands in a sustainable and efficient manner.

Advantages Over Traditional UV Light Sources

UV LED technology has made significant advancements in recent years, particularly with the development of 385nm UV LED technology. This innovative technology offers several advantages over traditional UV light sources, making it an attractive option for a wide range of applications.

One of the main advantages of 385nm UV LED technology is its energy efficiency. Traditional UV light sources, such as mercury vapor lamps, consume a significant amount of energy and produce a large amount of heat. In contrast, 385nm UV LED technology requires much less energy to operate and generates minimal heat, making it more energy-efficient and cost-effective. This energy efficiency also contributes to a longer lifespan for 385nm UV LEDs, reducing maintenance costs and downtime.

In addition to energy efficiency, 385nm UV LED technology also offers improved safety and environmental benefits. Unlike traditional UV light sources, which contain hazardous materials such as mercury, 385nm UV LEDs are free from harmful substances, making them safer for both the environment and human health. This is particularly important for applications where UV light is used in close proximity to people or sensitive materials.

Another significant advantage of 385nm UV LED technology is its precise wavelength control. Traditional UV light sources emit a broad spectrum of UV wavelengths, which can be challenging to control and optimize for specific applications. In contrast, 385nm UV LEDs have a narrow bandwidth, allowing for precise control over the emitted UV light. This precise wavelength control makes 385nm UV LEDs an ideal choice for applications requiring specific UV wavelengths, such as UV curing and UV sterilization.

Furthermore, 385nm UV LED technology offers improved performance and reliability compared to traditional UV light sources. 385nm UV LEDs can be designed to deliver high-intensity UV light output with consistent performance over time. This level of performance and reliability is crucial for applications that require consistent UV light output, such as UV printing and lithography.

The compact size and durability of 385nm UV LEDs are also important advantages over traditional UV light sources. 385nm UV LEDs are available in small form factors, making them suitable for integration into compact and portable devices. Additionally, 385nm UV LEDs are resistant to shock and vibration, making them well-suited for demanding industrial applications.

In conclusion, 385nm UV LED technology offers numerous advantages over traditional UV light sources, including energy efficiency, safety, precise wavelength control, improved performance, and durability. As a result, 385nm UV LEDs are becoming increasingly popular for a wide range of applications, including UV curing, UV sterilization, UV printing, and more. With ongoing advancements in UV LED technology, the potential of 385nm UV LEDs is likely to continue to expand, offering even more benefits and opportunities in the future.

Current Research and Development in 385nm UV LED Technology

The exploration of the potential of 385nm UV LED technology has been an area of great interest and significance in recent years. With continuous research and development in this field, the potential applications and benefits of this technology have expanded significantly. In this article, we will delve into the current research and development in 385nm UV LED technology, and the potential it holds for various industries and sectors.

In recent years, there has been a growing focus on the development and utilization of UV LED technology. The specific wavelength of 385nm UV LED has garnered attention due to its wide range of potential applications in areas such as sterilization, disinfection, and curing processes. Researchers and engineers have been actively working on enhancing the performance and efficiency of 385nm UV LED technology to meet the increasing demands of various industries.

One of the key areas of current research and development in 385nm UV LED technology is in the field of sterilization and disinfection. The 385nm wavelength is particularly effective in destroying bacteria, viruses, and other harmful microorganisms. This has significant implications for industries such as healthcare, pharmaceuticals, food and beverage, and water treatment. Researchers have been exploring the use of 385nm UV LED technology to develop more effective and efficient sterilization and disinfection systems, which can help in combating the spread of infectious diseases and ensuring safety and hygiene in various environments.

Another area of focus in the current research and development of 385nm UV LED technology is in the field of curing processes. The 385nm wavelength is ideal for curing UV-sensitive materials such as inks, adhesives, coatings, and resins. This has widespread applications in industries such as printing, electronics, automotive, and aerospace, where precise and efficient curing processes are essential. Researchers are working on enhancing the intensity and uniformity of 385nm UV LED light sources to improve the curing capabilities and overall performance of these processes.

The development of 385nm UV LED technology also presents opportunities for advancements in other fields such as fluorescence excitation, phototherapy, and environmental monitoring. The unique properties of 385nm UV LED light, including its narrow bandwidth and high energy output, make it well-suited for various specialized applications. Researchers are exploring the potential of 385nm UV LED technology in these areas to create innovative solutions that can address specific challenges and requirements.

In conclusion, the current research and development in 385nm UV LED technology is paving the way for significant advancements and innovations in various industries and sectors. The potential of this technology in sterilization, disinfection, curing processes, and other specialized applications is driving continuous efforts to enhance its performance and capabilities. With ongoing research and development, the possibilities for 385nm UV LED technology are poised to grow even further, opening up new opportunities for addressing complex challenges and improving the efficiency and sustainability of diverse processes.

Future Trends and Potential Innovations in 385nm UV LED Technology

The rapid advancement and development of UV LED technology have brought about significant innovations in various industries. Among the latest trends is the emergence of 385nm UV LED technology, which is poised to revolutionize the way UV light is utilized in various applications. In this article, we will explore the potential of 385nm UV LED technology and the future trends and innovations that are expected to drive its widespread adoption.

UV LED technology has been widely used in applications such as curing, disinfection, and medical treatments. The development of 385nm UV LED technology opens up new possibilities for even more efficient and effective utilization of UV light. At a wavelength of 385nm, these LEDs are capable of producing UV light in the UVA spectrum, which is known for its ability to induce photopolymerization and initiate chemical reactions. This makes 385nm UV LED technology particularly well-suited for UV curing processes in industries such as printing, adhesives, and coatings.

One of the key trends in 385nm UV LED technology is its increasing adoption in the field of disinfection and sterilization. With the ongoing global emphasis on hygiene and sanitation, there is a growing demand for effective and energy-efficient UV disinfection solutions. 385nm UV LEDs have shown great potential in this area, as they are capable of effectively deactivating bacteria, viruses, and other pathogens. Moreover, the use of UV LEDs for disinfection purposes eliminates the need for harmful chemical disinfectants, making it a safer and more environmentally friendly alternative.

Another potential innovation in 385nm UV LED technology lies in its application in medical treatments. Research has shown that UVA light at 385nm wavelength can stimulate the production of vitamin D in the human body, which is essential for bone health and immune function. This opens up possibilities for the development of UV LED-based devices for therapeutic purposes, such as treating vitamin D deficiency or certain skin conditions. Furthermore, 385nm UV LED technology can also be utilized in phototherapy for the treatment of certain skin disorders, offering a non-invasive and targeted approach to addressing these ailments.

In addition to these applications, the future of 385nm UV LED technology also holds promise in the realm of optical sensing and imaging. The unique properties of UVA light at 385nm wavelength make it suitable for fluorescence-based detection and imaging. This has implications for medical diagnostics, forensic science, and environmental monitoring, where the ability to detect specific substances or compounds through fluorescence can be invaluable. The development of UV LED-based sensing and imaging systems at 385nm holds potential for enhanced accuracy, sensitivity, and portability in various analytical and diagnostic processes.

In conclusion, the emergence of 385nm UV LED technology represents a significant development in the realm of UV light sources. Its potential for driving innovations in UV curing, disinfection, medical treatments, and optical sensing is shaping the future of numerous industries. As research and development in this field continues to advance, we can expect to see even more exciting applications and breakthroughs in the use of 385nm UV LED technology, ultimately leading to safer, more efficient, and more sustainable solutions for a wide range of challenges.

Conclusion

In conclusion, the potential of 385nm UV LED technology is truly remarkable. With its ability to offer precise and efficient curing solutions across a wide range of applications, the possibilities for its use are endless. As a company with 20 years of experience in the industry, we are excited to explore and harness the full potential of this technology to continue offering innovative and advanced solutions to our customers. With the rapid advancements in UV LED technology, we are confident that it will continue to revolutionize the way we approach curing processes and look forward to the exciting developments that lie ahead.