Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Exploring The Benefits Of UV LED 405nm Technology

Welcome to our exploration of the benefits of UV LED 405nm technology. In this article, we delve deep into the world of UV LED technology and its numerous advantages such as energy efficiency, longer lifespan, and superior performance. Join us as we uncover the potential of UV LED 405nm technology and its applications across various industries. Whether you're a tech enthusiast, a business owner, or simply curious about the latest innovations, this article is sure to pique your interest. Keep reading to discover the transformative capabilities of UV LED 405nm technology.

- Introduction to UV LED 405nm Technology

UV LED 405nm technology has quickly become a game-changer in the field of UV lighting, offering numerous benefits and advantages over traditional UV lamps. In this article, we will explore the various benefits of UV LED 405nm technology, its applications, and how Tianhui is leading the way in harnessing this innovative technology.

First and foremost, it is essential to understand what UV LED 405nm technology is and how it differs from traditional UV lamps. UV LED 405nm refers to the use of light-emitting diodes (LEDs) that emit ultraviolet light at a wavelength of 405 nanometers. This specific wavelength is particularly effective for various applications, including curing, sterilization, and fluorescence excitation. Unlike traditional UV lamps, UV LED 405nm technology does not produce heat or contain harmful mercury, making it more energy-efficient and environmentally friendly.

One of the primary benefits of UV LED 405nm technology is its energy efficiency and long lifespan. Tianhui's UV LED 405nm products consume significantly less energy than traditional UV lamps, resulting in lower operating costs and reduced environmental impact. Additionally, UV LED 405nm technology has a longer lifespan, reducing the frequency of replacement and maintenance, further lowering overall costs for businesses and organizations.

Furthermore, UV LED 405nm technology offers precise and consistent UV output, resulting in improved performance and productivity across various applications. Tianhui has leveraged this technology to develop high-performance UV curing systems that provide accurate and uniform curing of inks, coatings, adhesives, and other materials. This level of precision and consistency is essential for industries such as printing, electronics, and medical device manufacturing, where product quality and efficiency are paramount.

In addition to its energy efficiency and precision, UV LED 405nm technology is also known for its instant on/off capability and reduced thermal impact. Traditional UV lamps require a warm-up period and generate significant heat during operation, which can be detrimental to heat-sensitive materials and equipment. UV LED 405nm technology, on the other hand, can be instantly turned on and off, eliminating the need for warm-up time and minimizing the risk of heat damage.

Tianhui has been at the forefront of harnessing the benefits of UV LED 405nm technology, developing a wide range of UV LED 405nm products tailored to meet the specific needs of various industries. From highly efficient UV curing systems to powerful sterilization and fluorescence excitation solutions, Tianhui's UV LED 405nm technology is revolutionizing how businesses and organizations approach UV lighting.

In conclusion, UV LED 405nm technology offers a host of benefits, including energy efficiency, long lifespan, precision, consistency, instant on/off capability, and reduced thermal impact. Tianhui is committed to leveraging this innovative technology to provide cutting-edge UV LED 405nm solutions that drive performance, productivity, and sustainability across diverse industries. As the demand for environmentally friendly and high-performance UV lighting continues to grow, UV LED 405nm technology is poised to play a pivotal role in shaping the future of UV lighting technology.

- Understanding the Advantages of UV LED 405nm Technology

In the fast-paced world of technological advancements, it is essential for industries to stay updated with the latest innovations to ensure efficiency and productivity. One such innovation that has gained prominence in recent times is UV LED 405nm technology. This article aims to delve deeper into the advantages of this cutting-edge technology and how it can benefit various industries.

UV LED 405nm technology, also known as ultraviolet light emitting diode with a wavelength of 405 nanometers, has revolutionized the way UV curing processes are carried out. UV curing is a process that involves using UV light to instantly dry and cure inks, coatings, adhesives, and other materials. Traditional UV curing systems utilize mercury vapor lamps, which are bulky, have a short lifespan, and require frequent maintenance. In contrast, UV LED 405nm technology offers numerous advantages that make it a superior choice for UV curing applications.

One of the key advantages of UV LED 405nm technology is its energy efficiency. Compared to traditional mercury vapor lamps, UV LED 405nm technology consumes significantly less power, resulting in lower operating costs and reduced energy consumption. This makes it a more sustainable and environmentally friendly option for industries looking to minimize their carbon footprint.

Additionally, UV LED 405nm technology offers improved process control and consistency. The precise wavelength of 405nm ensures uniform curing and better adhesion, resulting in higher quality finished products. This is particularly beneficial for industries such as printing, automotive, electronics, and medical devices, where consistent and reliable curing is essential.

Furthermore, UV LED 405nm technology is known for its instant on/off feature, eliminating the need for warm-up or cool-down times. This not only increases productivity but also reduces downtime and overall production lead times. The instant curing capabilities of UV LED 405nm technology can lead to significant time and cost savings for industries with high-volume production requirements.

As a leading provider of UV LED 405nm technology, Tianhui has been at the forefront of developing innovative solutions to meet the evolving needs of industries. With our state-of-the-art UV LED 405nm systems, we offer superior performance, reliability, and flexibility to cater to a wide range of applications. Our commitment to research and development ensures that our UV LED 405nm technology remains at the cutting edge, providing our customers with the competitive advantage they need.

In conclusion, the advantages of UV LED 405nm technology are undeniable. From energy efficiency and process control to instant curing capabilities, this technology offers a myriad of benefits for industries seeking to enhance their production processes. As the market leader in UV LED 405nm technology, Tianhui is dedicated to providing our customers with the most advanced and reliable solutions to drive their success. With our technological expertise and commitment to excellence, we are poised to shape the future of UV curing applications and pave the way for a more sustainable and efficient industrial landscape.

- Applications and Uses of UV LED 405nm Technology

UV LED 405nm technology is a revolutionary advancement in the field of ultraviolet light-emitting diodes. This technology has opened up a wide range of applications and uses that were not possible with traditional UV lighting methods. In this article, we will delve into the various benefits of UV LED 405nm technology and how it is being utilized in different industries.

One of the key advantages of UV LED 405nm technology is its energy efficiency. Unlike traditional UV lamps, UV LED 405nm lights consume less power, making them more cost-effective and environmentally friendly. This is a significant benefit for businesses looking to reduce their energy consumption and lower their carbon footprint. As a leading manufacturer of UV LED 405nm technology, Tianhui is committed to delivering high-quality and energy-efficient lighting solutions to our customers.

In addition to energy efficiency, UV LED 405nm technology also offers superior performance and durability. These lights have a longer lifespan and can withstand frequent switching on and off without any degradation in performance. This makes them ideal for applications that require continuous and reliable UV light exposure, such as UV curing, water and air purification, and sterilization. As a result, many industries are adopting UV LED 405nm technology to enhance their processes and improve the quality of their products.

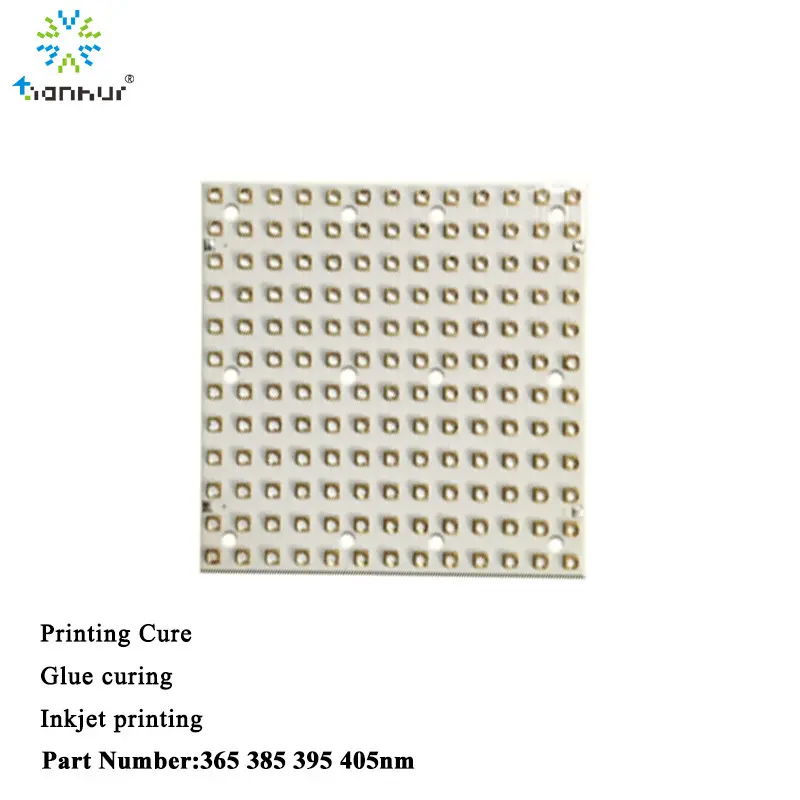

Some of the key applications of UV LED 405nm technology include UV curing in the printing and coating industry. These lights are used to cure inks, adhesives, and coatings on various substrates, resulting in faster production times and higher quality finishes. UV LED 405nm lights are also used in water and air purification systems to eliminate harmful microorganisms and pollutants. Furthermore, the medical and healthcare industry utilizes UV LED 405nm technology for sterilization purposes, ensuring the safety and cleanliness of medical instruments and equipment.

As a leading provider of UV LED 405nm technology, Tianhui offers a wide range of products tailored to meet the diverse needs of different industries. Our UV LED 405nm lights are designed to deliver powerful and consistent UV output, making them ideal for demanding applications. At Tianhui, we are committed to staying at the forefront of UV LED technology and continuously innovating to provide our customers with cutting-edge solutions.

In conclusion, UV LED 405nm technology has revolutionized the way we harness the power of ultraviolet light. Its energy efficiency, superior performance, and diverse applications make it an invaluable asset for various industries. As a leading manufacturer in the field, Tianhui is dedicated to providing high-quality UV LED 405nm products to meet the evolving needs of our customers. We are excited to see how this technology will continue to drive advancements and create new possibilities in the future.

- Comparative Analysis of UV LED 405nm Technology with Traditional UV Technology

The use of UV technology has been widely adopted in various industries for its ability to cure adhesives, coatings, and inks rapidly and efficiently. However, advancements in UV LED 405nm technology have offered a new and improved alternative to traditional UV technology. In this article, we will explore the benefits of UV LED 405nm technology in comparison to traditional UV technology, and how our brand, Tianhui, is at the forefront of this innovative technology.

UV LED 405nm technology has gained attention for its lower energy consumption and longer lifespan compared to traditional UV technology. These benefits not only contribute to cost savings but also to environmental sustainability. Tianhui has been committed to developing and producing UV LED 405nm technology that is not only efficient but also eco-friendly.

In terms of energy consumption, UV LED 405nm technology requires significantly less power to operate than traditional UV technology. This means that companies using UV LED 405nm technology can reduce their electricity consumption, resulting in lower operational costs and a smaller carbon footprint. Additionally, the longer lifespan of UV LED 405nm technology means that it requires less frequent replacement, reducing maintenance costs and minimizing waste.

One of the key advantages of UV LED 405nm technology is its ability to offer precise and consistent curing. Traditional UV technology can sometimes struggle with achieving uniform curing, leading to potential quality issues in the end product. However, UV LED 405nm technology provides a more controlled and focused curing process, resulting in higher quality and more reliable curing outcomes. Tianhui's UV LED 405nm technology has been designed to deliver precise curing results, ensuring the highest level of product quality for our customers.

Furthermore, UV LED 405nm technology is safer to use as it eliminates the need for mercury, which is present in traditional UV lamps. This not only reduces the environmental impact but also minimizes the potential health risks associated with mercury exposure. Tianhui is proud to offer a safer and more sustainable UV LED 405nm technology that aligns with our commitment to the well-being of our customers and the environment.

Finally, UV LED 405nm technology offers greater flexibility and versatility in terms of design and integration. The compact size and customizable nature of UV LED 405nm technology make it suitable for a wide range of applications, from industrial manufacturing processes to medical and cosmetic procedures. Tianhui's UV LED 405nm technology can be tailored to meet the specific needs of our customers, providing a seamless integration into their existing systems.

In conclusion, the comparative analysis of UV LED 405nm technology with traditional UV technology clearly highlights the numerous benefits and advantages of UV LED 405nm technology. Tianhui remains at the forefront of this innovative technology, offering efficient, eco-friendly, and reliable UV LED 405nm solutions for various industries. As the demand for sustainable and high-performance curing solutions continues to grow, UV LED 405nm technology is poised to reshape the future of UV technology.

- Conclusion: The Future of UV LED 405nm Technology

UV LED 405nm technology has been making waves in various industries, from healthcare to electronics, and its future looks promising. As we wrap up our exploration of the benefits of this cutting-edge technology, it's important to ponder on its potential advancements and the impact it could have on the world moving forward.

First and foremost, the future of UV LED 405nm technology holds great promise in the field of healthcare. With its ability to effectively disinfect and sterilize surfaces and equipment, this technology can play a significant role in preventing the spread of infections and diseases in medical facilities. As the demand for more efficient and sustainable healthcare solutions continues to rise, UV LED 405nm technology is well-positioned to become a mainstay in hospitals, clinics, and laboratories around the world.

Moreover, the potential applications of UV LED 405nm technology in the electronics industry are vast. From curing adhesives and coatings to printing circuit boards, this technology offers faster processing times, lower energy consumption, and reduced waste compared to traditional methods. As the electronics industry constantly seeks ways to improve production efficiency and minimize environmental impact, UV LED 405nm technology is poised to revolutionize manufacturing processes and set new industry standards.

In the realm of environmental sustainability, UV LED 405nm technology also holds promise. Its energy efficiency and long lifespan contribute to reduced carbon emissions and lower overall environmental footprint. As global efforts to combat climate change intensify, the adoption of UV LED 405nm technology across various industries can make a significant contribution to a more sustainable future.

Looking ahead, Tianhui is dedicated to driving the advancement and adoption of UV LED 405nm technology. With our extensive experience and expertise in LED technology, we are committed to developing innovative solutions that harness the full potential of UV LED 405nm for the benefit of our customers and the planet. Our ongoing research and development efforts are focused on enhancing the performance, durability, and versatility of UV LED 405nm technology, with the aim of delivering cutting-edge solutions that address the evolving needs of diverse industries.

Furthermore, our dedication to quality and reliability ensures that our UV LED 405nm products meet the highest industry standards, providing our customers with a sustainable and cost-effective alternative to traditional UV technologies. As we look to the future, we are excited about the possibilities that UV LED 405nm technology presents and the positive impact it can have on the world.

In conclusion, the future of UV LED 405nm technology is bright, and its potential to transform various industries is immense. From healthcare and electronics to environmental sustainability, the benefits of UV LED 405nm technology are clear, and its trajectory points towards a sustainable and innovative future. With Tianhui at the forefront of this technology, we are committed to driving its advancement and making a positive impact on the world. As we continue to explore and harness the potential of UV LED 405nm technology, we are excited about the possibilities that lie ahead and the positive change it can bring to the world.

Conclusion

In conclusion, the exploration of the benefits of UV LED 405nm technology has shed light on the numerous advantages it offers across various industries. With our 20 years of experience in the industry, we have witnessed the transformative power of this technology in improving productivity, efficiency, and product quality. From curing adhesives and coatings to sterilizing medical equipment, the applications of UV LED 405nm technology are vast and promising. As we continue to delve deeper into its potential, we look forward to further advancements and innovations that will undoubtedly shape the future of manufacturing and beyond.