Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Exploring The Benefits And Applications Of 395nm LED Technology

Welcome to our exploration of the innovative world of 395nm LED technology. In this article, we will delve into the numerous benefits and diverse applications of this cutting-edge lighting technology. From its potential in medical and scientific fields to its impact on creative and practical industries, 395nm LED technology is revolutionizing the way we illuminate and innovate. Join us as we uncover the possibilities and advantages of this exciting advancement in lighting.

Understanding the Potential of 395nm LED Technology

As technology continues to advance, the potential of 395nm LED technology is becoming increasingly apparent. These high-powered ultraviolet (UV) LEDs have numerous benefits and applications, making them a valuable asset in various industries. In this article, we will explore the benefits and applications of 395nm LED technology, providing a comprehensive understanding of its potential.

First and foremost, it is essential to understand the science behind 395nm LED technology. These LEDs emit light at a wavelength of 395 nanometers, falling within the UV-A spectrum. UV-A light has a wavelength range of 320-400nm and is commonly used in various applications due to its ability to cause certain materials and substances to fluoresce. This property makes 395nm LEDs particularly useful in applications such as UV curing, counterfeit detection, and fluorescence excitation.

One of the primary benefits of 395nm LED technology is its efficiency and longevity. Compared to traditional light sources, LED technology is significantly more energy-efficient and has a longer lifespan. This means that 395nm LEDs can provide a consistent and reliable source of UV light for extended periods, making them ideal for industrial and commercial applications.

Additionally, 395nm LED technology offers precise and controllable output, allowing for tailored solutions in various applications. The ability to control the intensity and duration of UV light exposure is crucial in processes such as UV curing, where precise dosing of UV light is necessary to achieve optimal results. With 395nm LEDs, manufacturers can achieve greater control and consistency in their production processes, leading to improved quality and efficiency.

Furthermore, the compact size and low heat output of 395nm LEDs make them versatile and easy to integrate into existing systems. Whether used in handheld devices for forensic applications or integrated into automated production lines for UV curing, the small form factor of 395nm LEDs allows for flexibility in design and implementation. This versatility is a significant advantage in industries where space and heat management are critical factors.

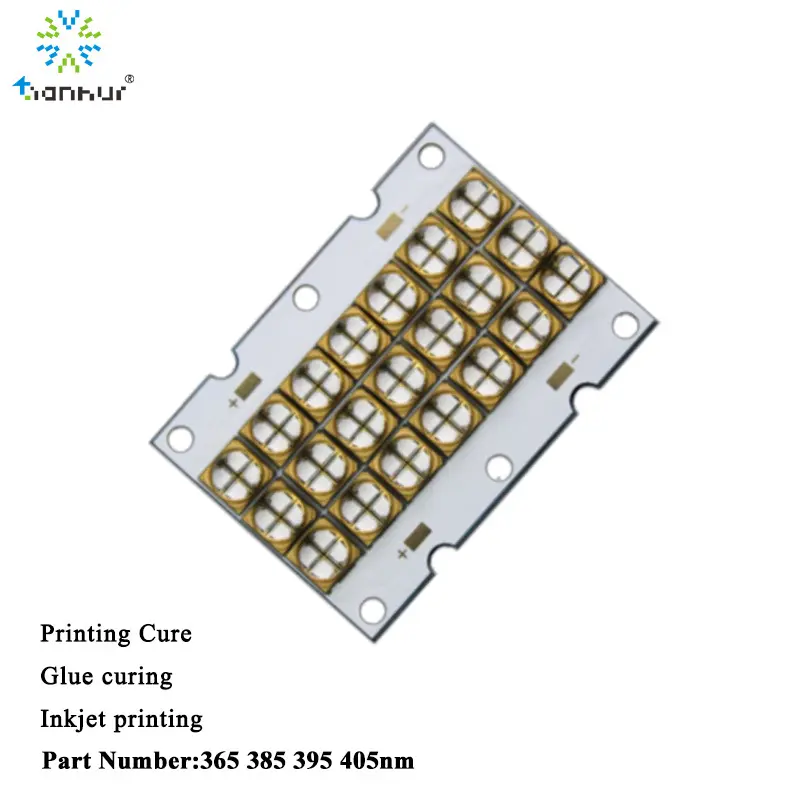

The applications of 395nm LED technology are diverse and wide-ranging. In the field of UV curing, 395nm LEDs are utilized for the rapid curing of adhesives, coatings, and inks in industries such as electronics, automotive, and printing. The precise and efficient curing capabilities of 395nm LEDs enable faster production speeds and improved product quality.

Additionally, 395nm LED technology is valuable in counterfeit detection and security applications. The ability of UV light to reveal hidden features and markings on documents, banknotes, and products makes 395nm LEDs an essential tool in fraud prevention and detection. The use of 395nm LEDs in forensic science for crime scene investigation and evidence analysis further demonstrates their significance in security and law enforcement.

In conclusion, the potential of 395nm LED technology is vast and continues to expand as new applications are discovered. The efficiency, versatility, and precision of 395nm LEDs make them an invaluable asset in industries such as manufacturing, security, and forensic science. As technology advances, the potential of 395nm LED technology will only continue to grow, offering new and innovative solutions to meet the evolving needs of various industries.

Advantages of Using 395nm LED Technology in Various Applications

There are numerous advantages to using 395nm LED technology in a wide range of applications. From its ability to provide high-energy and efficient lighting to its diverse array of applications in areas such as medicine, forensics, and manufacturing, 395nm LED technology is a versatile and valuable tool.

One of the key advantages of 395nm LED technology is its ability to provide high-energy lighting. The 395nm wavelength falls within the ultraviolet range, specifically within the UVA spectrum. This means that 395nm LEDs emit light with a relatively high energy level, making them ideal for applications where strong, focused light is needed. In comparison to traditional light sources, 395nm LED technology offers a more powerful and efficient lighting solution.

In addition to its high-energy output, 395nm LED technology has found a range of applications across various industries. In the field of medicine, 395nm LEDs are used for phototherapy, which is the treatment of certain skin conditions using light. The high-energy output of 395nm LEDs allows for targeted and effective treatment, making them an invaluable tool in dermatology and other medical specialties. In the field of forensics, 395nm LEDs are used for crime scene investigation, as they can reveal bodily fluids, trace evidence, and other materials that are not visible to the naked eye. This makes 395nm LED technology an essential component of forensic investigation and evidence collection.

Moreover, 395nm LED technology is also widely used in manufacturing and industrial settings. These LEDs can be used for curing adhesives, inks, and coatings, providing a more efficient and cost-effective alternative to traditional curing methods. In addition, 395nm LEDs are used for fluorescence-based inspection and quality control in manufacturing, as they can reveal defects and inconsistencies that may not be visible under ordinary lighting conditions. These applications demonstrate the broad utility of 395nm LED technology in diverse industrial and commercial environments.

In conclusion, the advantages of using 395nm LED technology in various applications are clear. From its high-energy output to its diverse array of applications in medicine, forensics, and manufacturing, 395nm LED technology offers unparalleled versatility and efficiency. As advancements continue to be made in LED technology, the potential applications and benefits of 395nm LEDs will only expand, further solidifying their status as a valuable and indispensable lighting solution.

Exploring the Versatile Applications of 395nm LED Technology

In recent years, 395nm LED technology has gained significant attention for its numerous benefits and versatile applications across various industries. This article aims to delve into the wide range of uses and advantages of this groundbreaking technology, shedding light on its potential to revolutionize a multitude of sectors.

The 395nm LED technology has garnered attention for its ability to emit ultraviolet light at a wavelength of 395 nanometers. This specific wavelength enables it to be utilized in a variety of applications, ranging from sterilization and disinfection to counterfeit detection and industrial processes.

One of the most notable applications of 395nm LED technology is in the field of sterilization and disinfection. Its ability to emit ultraviolet light at 395nm makes it highly effective in killing bacteria, viruses, and fungi, making it an indispensable tool in healthcare facilities, laboratories, and food processing plants. The technology's ability to eradicate harmful microorganisms has proven to be crucial, especially in light of recent global health concerns.

Moreover, 395nm LED technology has been widely adopted for counterfeit detection and authentication purposes. The unique properties of ultraviolet light at this wavelength allow it to reveal hidden features in banknotes, identification cards, and various security documents. This has become an invaluable tool for law enforcement agencies, financial institutions, and government entities in their efforts to combat counterfeiting and fraud.

Beyond its applications in healthcare and security, 395nm LED technology has proven to be instrumental in various industrial processes. Its ability to cure adhesives, inks, and coatings at a specific wavelength has made it a preferred choice for manufacturers seeking efficient and reliable curing solutions. Additionally, the technology's use in fluorescence-based inspection and non-destructive testing has significantly enhanced quality control and inspection processes in industries such as automotive, electronics, and aerospace.

The versatility of 395nm LED technology extends to its integration in horticulture and agriculture. By providing specific wavelengths of light, these LEDs can optimize plant growth, flowering, and fruiting, making them valuable assets for indoor farming, greenhouse cultivation, and research facilities. This has resulted in increased crop yields, improved plant health, and reduced energy consumption, contributing to sustainable agricultural practices.

In addition to its practical applications, the energy efficiency and long lifespan of 395nm LED technology make it an environmentally-friendly option. Its low power consumption and minimal heat generation make it an attractive choice for businesses and industries striving to reduce their carbon footprint and operational costs.

In conclusion, the versatile applications of 395nm LED technology have propelled it to become an essential component across various industries. From sterilization and counterfeit detection to industrial processes and horticulture, the benefits of this technology are broad and profound. As advancements in LED technology continue to unfold, the potential for further applications and innovations in the 395nm LED space remains promising, paving the way for a brighter future across multiple sectors.

Comparing 395nm LED Technology with Traditional UV Light Sources

The rapid advancement of LED technology has revolutionized the way we use light sources in various applications. One area where this has had a significant impact is in the field of ultraviolet (UV) light sources. In this article, we will explore the benefits and applications of 395nm LED technology in comparison to traditional UV light sources.

395nm LED technology has emerged as a popular choice for UV light applications due to its numerous advantages over traditional UV light sources. The primary advantage of 395nm LED technology is its efficiency and energy-saving capabilities. LEDs are known for their low power consumption, and the same applies to 395nm LED technology. This makes it a more cost-effective and environmental-friendly option compared to traditional UV light sources.

Furthermore, 395nm LED technology offers a longer lifespan compared to traditional UV light sources. LEDs have a much longer operational life, which means they require less frequent replacement and maintenance, saving both time and money in the long run. This makes them a more reliable and sustainable option for UV light applications.

In addition to its efficiency and longevity, 395nm LED technology also offers better control and precision in UV light applications. LEDs can be easily dimmed and controlled, allowing for flexibility in various applications. This level of control is especially important in applications such as UV curing, UV printing, and UV sterilization, where precise control of UV light intensity is crucial.

Another significant advantage of 395nm LED technology is its safety benefits. Traditional UV light sources, such as mercury vapor lamps, can pose safety hazards due to the presence of toxic materials. In contrast, 395nm LED technology is free from hazardous materials, making it a safer option for both the environment and human health.

The applications of 395nm LED technology are diverse and widespread. One of the most common applications is UV curing, where the precise control and efficiency of 395nm LED technology are highly beneficial. UV curing is used in various industries, including printing, electronics, and manufacturing, for applications such as adhesives, coatings, and inks. The efficiency and longevity of 395nm LED technology make it an ideal choice for UV curing applications.

395nm LED technology is also used in UV printing, where its precision and control capabilities are put to good use. UV printing is widely used in industries such as signage, packaging, and labeling, and the efficiency and safety benefits of 395nm LED technology are highly valuable in this application.

Furthermore, 395nm LED technology is utilized in UV sterilization applications, where its safety and energy-saving benefits are particularly important. UV sterilization is used in various settings, including medical facilities, laboratories, and water treatment plants, and the efficiency and safety of 395nm LED technology make it a superior choice for these applications.

In conclusion, 395nm LED technology offers numerous benefits and advantages over traditional UV light sources. Its efficiency, longevity, precision, and safety benefits make it an ideal choice for a wide range of UV light applications. As LED technology continues to evolve, 395nm LED technology is expected to play an increasingly significant role in the field of UV light sources.

Future Developments and Innovations in 395nm LED Technology

LED (light-emitting diode) technology has advanced significantly in recent years, and the development of LEDs emitting light at specific wavelengths has opened up a wide range of new possibilities in various industries. One such wavelength that has garnered significant attention is 395nm. In this article, we will explore the benefits and applications of 395nm LED technology, as well as future developments and innovations in this area.

At the heart of 395nm LED technology is the utilization of ultraviolet (UV) light. With a wavelength of 395nm, these LEDs fall within the UVA spectrum, making them particularly useful for a variety of applications. One of the primary benefits of 395nm LED technology is its ability to effectively and efficiently disinfect and sterilize surfaces, air, and water. This has important implications for healthcare facilities, food and beverage processing, and water treatment systems. The UV light emitted by 395nm LEDs is capable of destroying harmful microorganisms, including bacteria, viruses, and mold, without the use of harsh chemicals.

In addition to its disinfecting properties, 395nm LED technology also has applications in UV curing processes. UV curing is a technology used to instantly dry and cure inks, coatings, adhesives, and other materials. The use of 395nm LEDs in UV curing applications offers numerous advantages, including faster curing times, lower energy consumption, and reduced environmental impact compared to traditional curing methods.

Looking towards the future, there are several key developments and innovations that are likely to shape the 395nm LED technology landscape. One area of focus is the continued improvement of LED efficiency and lifespan. Researchers and manufacturers are working to develop 395nm LEDs that are even more energy-efficient and have longer operational lifespans, making them more cost-effective and environmentally friendly. Additionally, advancements in 395nm LED packaging and integration are expected to lead to more compact, durable, and versatile LED products, expanding their potential use in a wider range of applications.

Another area of innovation in 395nm LED technology is the development of tailored light spectrums to target specific biological and chemical processes. By fine-tuning the spectral output of 395nm LEDs, it may be possible to enhance their disinfection capabilities, improve UV curing outcomes, and potentially even enable new applications in areas such as phototherapy and medical diagnostics.

Furthermore, research in materials science and nanotechnology is poised to play a significant role in advancing 395nm LED technology. The development of new materials and nanostructures can lead to LEDs with improved performance, enhanced thermal management, and greater flexibility in design and integration. These advancements could open up new opportunities for 395nm LED technology in areas such as wearable devices, automotive lighting, and advanced optics.

In conclusion, 395nm LED technology holds great promise for a wide range of applications, from disinfection and sterilization to UV curing and beyond. As research and development in this field continue to progress, we can expect to see even more exciting developments and innovations that will further expand the possibilities of 395nm LED technology. The future of 395nm LED technology is indeed bright, and its potential to make a positive impact on multiple industries is undeniable.

Conclusion

In conclusion, after exploring the benefits and applications of 395nm LED technology, it is clear that this innovative technology has revolutionized various industries including medical, industrial, and scientific fields. The numerous advantages such as energy efficiency, long lifespan, and precise wavelength control make 395nm LED technology a valuable asset in various applications. As a company with 20 years of experience in the industry, we are excited to continue to explore and harness the potential of 395nm LED technology to bring about further advancements and improvements in various sectors. With its ability to meet the specific requirements of different industries, 395nm LED technology has opened up a world of possibilities and continues to be a driving force behind technological advancements. As we look towards the future, we are eager to see how this technology will continue to evolve and benefit our world.