Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Exploring The Advantages Of LED UV SMD Technology

Are you curious about the latest technology in lighting and its potential benefits? In this article, we delve into the world of LED UV SMD technology and explore the numerous advantages it has to offer. From energy efficiency to cost savings, this innovative form of lighting is revolutionizing the industry. Join us as we uncover the many ways in which LED UV SMD technology is changing the game and why it's worth considering for your own needs.

Understanding the Basics of LED UV SMD Technology

As technology continues to advance, the use of LED UV SMD technology has become increasingly popular in various industries. In this article, we will explore the basics of LED UV SMD technology, its advantages, and how it can benefit businesses and individuals.

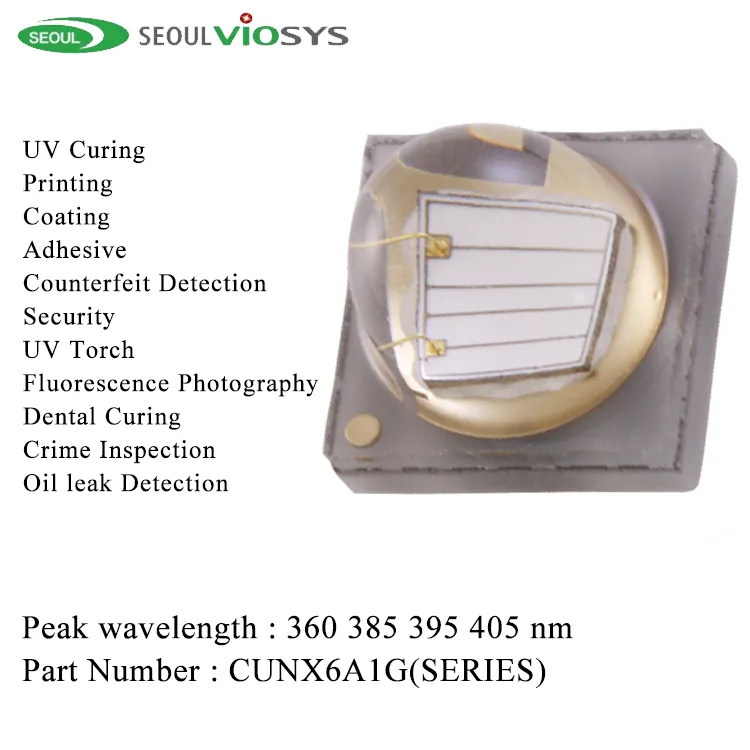

LED UV SMD technology is a form of ultraviolet (UV) light technology that uses light-emitting diodes (LEDs) and surface mount device (SMD) technology to produce UV light. This technology is used for a wide range of applications, including curing, printing, coating, and sterilization.

One of the key advantages of LED UV SMD technology is its energy efficiency. LED UV SMD lights consume less energy compared to traditional UV lamps, making them a more cost-effective and environmentally friendly option. Additionally, LED UV SMD lights have a longer lifespan, reducing the need for frequent replacements and maintenance.

Another advantage of LED UV SMD technology is its compact size and flexibility. LED UV SMD lights can be designed in various shapes and sizes, making them suitable for different applications. Their compact size also allows for easy integration into existing systems, making it convenient for businesses to adopt this technology.

Furthermore, LED UV SMD technology offers improved performance and control. Unlike traditional UV lamps, LED UV SMD lights can be instantly turned on and off, providing instant curing and reducing production time. Additionally, LED UV SMD lights can be dimmed and controlled to achieve the desired UV intensity, ensuring consistent results and quality.

Tianhui, a leading provider of LED UV SMD technology, offers a range of high-quality and customizable LED UV SMD lights for various applications. As a pioneer in the industry, Tianhui has been at the forefront of developing and innovating LED UV SMD technology, providing businesses and individuals with reliable and efficient solutions.

Whether it is for industrial curing, printing, or sterilization, Tianhui’s LED UV SMD lights are designed to meet the diverse needs of customers. With a focus on quality, efficiency, and sustainability, Tianhui is committed to delivering exceptional LED UV SMD technology that drives performance and productivity.

In conclusion, LED UV SMD technology is a versatile and efficient technology that offers numerous advantages for businesses and individuals. From energy efficiency and longer lifespan to improved performance and control, LED UV SMD technology is revolutionizing various industries. With Tianhui’s expertise and commitment to excellence, businesses and individuals can harness the power of LED UV SMD technology for their specific needs and applications.

Comparing the Advantages of LED UV SMD Technology to Traditional Methods

In recent years, the use of LED UV SMD technology has gained significant traction in various industries due to its numerous advantages over traditional methods. In this article, we will explore the many benefits of LED UV SMD technology and compare them to traditional methods, shedding light on why more and more businesses are making the switch.

LED UV SMD technology has many advantages, including energy efficiency, cost-effectiveness, and environmental friendliness. Compared to traditional UV lamps, LED UV SMD technology consumes significantly less power, resulting in lower energy costs for businesses. Additionally, LED UV SMD technology has a longer lifespan than traditional UV lamps, reducing the frequency of replacements and further lowering overall costs. Moreover, LED UV SMD technology does not contain mercury, making it a more environmentally friendly option.

Tianhui has been at the forefront of LED UV SMD technology, offering high-quality products that are not only efficient and cost-effective but also environmentally friendly. Our LED UV SMD technology has been widely adopted by businesses in various industries, from printing and packaging to electronics and automotive, due to its superior performance and durability.

One of the key advantages of LED UV SMD technology is its ability to provide instant curing, which significantly reduces production time and increases efficiency. Traditional UV lamps require warm-up time and may produce inconsistent curing results, whereas LED UV SMD technology delivers consistent and reliable curing instantly, resulting in improved productivity and reduced production costs.

Furthermore, LED UV SMD technology offers better control over the curing process, allowing for precise and uniform curing of coatings, inks, and adhesives. This level of control is difficult to achieve with traditional UV lamps, which often result in uneven curing and require meticulous adjustments. Tianhui's LED UV SMD technology ensures that businesses can achieve superior curing results consistently, leading to higher quality end products.

Another advantage of LED UV SMD technology is its compact size and flexibility, making it suitable for various applications and production environments. Traditional UV lamps are often bulky and may require dedicated space, whereas LED UV SMD technology can be integrated into existing production lines with minimal disruption. This flexibility allows businesses to optimize their production processes and adapt to changing requirements more easily.

In conclusion, LED UV SMD technology offers numerous advantages over traditional methods, including energy efficiency, cost-effectiveness, and environmental friendliness. Tianhui has been a pioneer in developing and implementing LED UV SMD technology, providing businesses with high-quality products that improve productivity, reduce costs, and enhance the quality of end products. As more businesses recognize the benefits of LED UV SMD technology, it is expected to become the standard in various industries, revolutionizing production processes and driving sustainable growth.

Exploring the Versatility and Applications of LED UV SMD Technology

In the ever-evolving world of technological advancements, LED UV SMD technology has emerged as a game-changer in various industries. From healthcare to manufacturing, this cutting-edge technology has proved its versatility and applicability in a multitude of fields. In this article, we will delve into the myriad advantages and applications of LED UV SMD technology, shedding light on its transformative potential and the role it plays in shaping the future of innovation.

LED UV SMD technology, short for Light-Emitting Diode Ultraviolet Surface-Mounted Device technology, has revolutionized the way ultraviolet light is used in various processes. As a leader in this field, Tianhui has been at the forefront of harnessing the power of LED UV SMD technology to create innovative solutions for a wide range of applications. With a commitment to excellence and a passion for pushing the boundaries of what is possible, Tianhui has solidified its position as a pioneer in this space.

One of the most notable advantages of LED UV SMD technology is its energy efficiency. Compared to traditional UV light sources, LED UV SMD technology consumes significantly less power, making it a more sustainable and cost-effective option. This reduced energy consumption not only leads to lower operational costs but also contributes to environmental conservation, aligning with Tianhui's dedication to sustainability and corporate responsibility.

Furthermore, LED UV SMD technology offers superior performance and reliability. With a longer lifespan and consistent output, LED UV SMD devices outperform their conventional counterparts, providing a more dependable and durable solution for various applications. This reliability is essential in critical industries such as healthcare, where consistent and effective disinfection is paramount. Tianhui's LED UV SMD technology has been instrumental in enhancing sterilization processes in healthcare facilities, safeguarding the health and well-being of patients and healthcare professionals.

In addition to its energy efficiency and reliability, LED UV SMD technology is incredibly versatile, finding applications in diverse sectors. From industrial manufacturing and printing to water and air purification, the possibilities are endless. Tianhui has leveraged the adaptability of LED UV SMD technology to develop custom solutions for its clients, addressing their specific needs and surpassing expectations.

The potential of LED UV SMD technology extends beyond traditional applications, with emerging fields such as phototherapy and 3D printing benefiting from its capabilities. Tianhui has been instrumental in driving innovation in these areas, collaborating with leading researchers and industry experts to explore new frontiers and unlock the full potential of LED UV SMD technology.

As we continue to explore the versatility and applications of LED UV SMD technology, it is evident that this groundbreaking technology has the power to redefine industries and drive sustainable progress. With Tianhui leading the way, the future looks brighter than ever, fueled by the transformative potential of LED UV SMD technology.

Examining the Environmental and Cost Benefits of LED UV SMD Technology

In recent years, the use of LED UV SMD (Surface Mounted Diode) technology has been gaining traction in various industries, and for good reason. This article aims to delve into the environmental and cost benefits of this cutting-edge technology, shedding light on its advantages and potential impact on businesses and the environment.

LED UV SMD technology boasts numerous advantages over conventional UV curing methods, making it an attractive option for businesses looking to improve their efficiency and sustainability. When compared to traditional UV lamps, LED UV SMD technology consumes significantly less energy, resulting in lower operating costs and reduced environmental impact. This is a major plus for businesses aiming to minimize their carbon footprint and contribute to a greener future.

One of the key environmental benefits of LED UV SMD technology is its minimal heat output. Unlike traditional UV lamps, which generate a substantial amount of heat, LED UV SMD technology produces little to no heat during operation. This not only reduces the risk of heat-related damage to sensitive substrates but also contributes to a cooler working environment, which can be particularly beneficial in manufacturing settings.

Furthermore, the longevity and durability of LED UV SMD technology contribute to its environmental advantages. LED bulbs have an impressive lifespan, often lasting significantly longer than traditional UV lamps. This means less frequent replacement and disposal of bulbs, ultimately reducing waste and the associated environmental impact. Additionally, the durability of LED UV SMD technology leads to fewer maintenance requirements, saving businesses time and resources in the long run.

From a cost perspective, the advantages of LED UV SMD technology are equally compelling. While the initial investment in LED UV SMD systems may be higher than traditional UV curing equipment, the long-term savings are substantial. The energy efficiency of LED UV SMD technology translates to lower electricity bills, and the extended lifespan of LED bulbs means reduced replacement and maintenance costs. Over time, businesses can expect to see significant returns on their investment in LED UV SMD technology, making it a financially prudent choice.

As a leading provider of LED UV SMD technology, Tianhui is committed to delivering innovative solutions that not only meet the needs of businesses but also contribute to a sustainable future. Our LED UV SMD systems are designed to optimize energy efficiency and minimize environmental impact, aligning with our brand's dedication to environmental responsibility.

In conclusion, the environmental and cost benefits of LED UV SMD technology make it a compelling choice for businesses across various industries. From reduced energy consumption and lower operating costs to minimal heat output and extended lifespan, the advantages of LED UV SMD technology are clear. As businesses continue to prioritize sustainability and efficiency, the adoption of LED UV SMD technology is poised to play a pivotal role in shaping the future of UV curing.

Implementing LED UV SMD Technology: Best Practices and Considerations

In recent years, LED UV SMD technology has become increasingly popular in various industries due to its numerous advantages. From improved efficiency to better environmental sustainability, this technology is revolutionizing the way we think about UV curing. In this article, we will explore the best practices and considerations for implementing LED UV SMD technology, with a specific focus on how Tianhui is leading the way in this innovative field.

One of the key advantages of LED UV SMD technology is its energy efficiency. Traditional UV curing systems often require a significant amount of energy to operate, leading to higher costs and environmental impact. LED UV SMD technology, on the other hand, uses significantly less energy while still providing powerful and consistent UV output. This not only reduces operating costs but also contributes to a greener, more sustainable business model.

When implementing LED UV SMD technology, it is crucial to consider the quality and reliability of the SMD components. At Tianhui, we have invested in rigorous testing and quality control measures to ensure that our LED UV SMD products meet the highest standards of performance and durability. Our state-of-the-art manufacturing facilities and advanced testing equipment allow us to consistently produce SMD components that deliver exceptional UV output and long-term reliability.

In addition to quality, it is important to consider the versatility of LED UV SMD technology. Different applications may require specific wavelength ranges or power levels, and Tianhui offers a wide range of LED UV SMD products to meet these diverse needs. Whether it is for industrial curing processes, printing applications, or other specialized uses, our LED UV SMD technology can be tailored to provide the optimal UV output for each unique application.

Furthermore, the compact size and low profile of LED UV SMD components make them a practical choice for integration into existing equipment and machinery. This allows for seamless retrofitting and easy integration into new production lines, providing a cost-effective and efficient solution for upgrading UV curing systems. With our expertise in LED UV SMD technology, Tianhui is dedicated to helping businesses maximize the benefits of this innovative technology while minimizing the disruptions to their operations.

Another consideration when implementing LED UV SMD technology is the potential for increased productivity and reduced downtime. The instant on/off capability of LED UV SMD components eliminates the need for warm-up or cool-down periods, allowing for faster curing cycles and greater overall efficiency. This can lead to significant improvements in production output and reduced reliance on costly and time-consuming maintenance procedures.

In conclusion, the advantages of LED UV SMD technology are clear, and the best practices for implementing this technology are rooted in quality, versatility, and productivity. With Tianhui at the forefront of LED UV SMD innovation, businesses can confidently embrace this technology with the knowledge that they are investing in reliable, efficient, and sustainable solutions. As the market for LED UV SMD technology continues to expand, Tianhui remains committed to delivering the highest quality components and supporting businesses in maximizing the benefits of this groundbreaking technology.

Conclusion

In conclusion, after exploring the numerous advantages of LED UV SMD technology, it is clear that this innovative technology offers a wide range of benefits for various industries. From its energy efficiency and long lifespan to its ability to produce high-quality, consistent results, LED UV SMD technology has proven to be a game-changer in the world of UV curing. As a company with 20 years of experience in the industry, we are excited about the potential that this technology holds for our business and are committed to staying at the forefront of these developments. We look forward to harnessing the power of LED UV SMD technology to drive our company forward and deliver even better results for our customers.