Tianhui- one of the leading UV LED chip manufacturers and suppliers provides ODM/OEM UV led chip service for over 22+ years.

Exploring The Advantages And Applications Of UV LED Boards: A Cutting-Edge Technology For Enhanced Performance

Welcome to our article on the fascinating world of UV LED boards! In this technological era, where advancements are constantly pushing the boundaries of innovation, we are thrilled to present a comprehensive exploration of the advantages and applications of UV LED boards. Delve into the realm of this cutting-edge technology that revolutionizes performance across various industries. Whether you are a tech enthusiast, a business owner, or simply curious about the latest breakthroughs, this article will uncover the immense potential and practicality of UV LED boards. Prepare to be amazed as we unravel the outstanding capabilities and unrivaled benefits that make UV LED boards a game-changer. Embark on this enlightening journey, and let us immerse you in the realm of enhanced performance achieved through this groundbreaking technology.

Understanding UV LED Technology: An Introduction to its Advantages

UV LED technology has emerged as a cutting-edge technology for various applications, offering numerous advantages over traditional lighting solutions. In this article, we will explore the advantages and applications of UV LED boards, a revolutionary technology that promises enhanced performance across a wide range of industries.

UV LED boards, developed by Tianhui, have revolutionized the way we perceive and utilize ultraviolet light. This technology involves the use of light-emitting diodes (LEDs) that emit ultraviolet light at a specific wavelength. Unlike conventional UV lamps, which rely on mercury vapor and produce harmful UV-C radiation, UV LED boards provide a safer and more efficient alternative.

The advantages of UV LED boards are numerous and diverse. Firstly, these boards offer a significantly longer lifespan as compared to traditional lamps. With average lifespans of up to 50,000 hours, UV LED boards are highly durable and require minimal maintenance. This longevity translates into cost savings for businesses, as they reduce the need for frequent replacements and repairs.

Moreover, UV LED boards are highly energy-efficient. Traditional UV lamps consume a significant amount of power, mainly due to their inefficient conversion of electricity into light. In contrast, UV LED boards have a higher conversion efficiency, resulting in reduced energy consumption. This not only saves on electricity costs but also has a positive environmental impact, as it decreases carbon emissions.

Another advantage of UV LED boards is their instant on/off feature. Unlike traditional UV lamps, which require warm-up time, UV LED boards emit full-strength light immediately upon activation. This feature enables quicker and more efficient production processes, as there is no need to wait for the lamps to reach their optimal working temperature. This contributes to increased productivity and reduced downtime for businesses.

In terms of safety, UV LED boards are a viable alternative to traditional UV lamps. Conventional UV lamps utilize mercury vapor, a toxic substance that poses health risks if mishandled or broken. UV LED boards, on the other hand, do not contain any hazardous materials, making them safer to use and handle. This is particularly important in industries where human exposure to UV light is unavoidable, such as medical and sterilization applications.

UV LED boards offer a wide range of applications across various industries. In the healthcare sector, they are used for germicidal disinfection, effectively killing bacteria, viruses, and other harmful microorganisms. This technology has the potential to revolutionize the healthcare industry by providing a safer and more efficient method of sterilization.

Furthermore, UV LED boards find application in the printing industry, specifically in UV curing systems. UV curable inks and coatings require UV radiation to cure and dry quickly. The precise wavelength emitted by UV LED boards ensures optimal curing and enhances the overall print quality. This technology enables faster production speeds and reduces the need for excessive heat, contributing to cost savings and improved print durability.

Additionally, UV LED boards are used in water and air purification systems. As UV light effectively sterilizes water and air by neutralizing harmful pathogens, UV LED boards offer a reliable and efficient method of purification. This technology is extensively used in residential, commercial, and industrial settings to ensure the safety and quality of the water and air we consume.

In conclusion, UV LED boards, developed by Tianhui, are a revolutionary technology that offers numerous advantages over traditional UV lamps. With their longer lifespan, energy efficiency, instant on/off feature, and safety benefits, UV LED boards are increasingly being adopted across various industries. The versatility and effectiveness of this technology make it a promising solution for enhanced performance in applications such as healthcare, printing, and purification systems.

Unveiling the Applications of UV LED Boards in Various Industries

UV LED boards, a cutting-edge technology developed by Tianhui, have taken the industrial world by storm, bringing with them a plethora of advantages and applications. These state-of-the-art boards harness the power of Ultraviolet (UV) light Emitting Diodes (LEDs) and offer enhanced performance compared to traditional lighting systems. In this article, we will delve into the multifaceted applications of UV LED boards across various industries and explore the many advantages they bring to the table.

One of the most significant advantages of UV LED boards is their energy efficiency. Traditional lighting systems often consume significant amounts of electricity, but UV LED boards are designed to be highly energy-efficient. They require less power to generate the same level of illumination, resulting in reduced energy costs and environmental impact. This aspect makes these boards ideal for industries seeking sustainable solutions.

The applications of UV LED boards span across various industries. In the healthcare industry, UV LED boards find extensive use in disinfection and sterilization processes. The powerful UV light emitted by these boards can effectively kill bacteria, viruses, and other microorganisms, making them invaluable in hospitals, laboratories, and other healthcare facilities. With the ability to eliminate up to 99.9% of germs, UV LED boards offer a more efficient alternative to traditional sanitization methods.

Another industry that greatly benefits from UV LED boards is the printing industry. These boards are used in UV curing processes, where the UV light emitted by the boards enables quick and efficient drying of inks and coatings. Compared to conventional drying methods, UV LED boards provide faster curing times, higher print quality, and improved overall production efficiency. This makes them indispensable in the printing of packaging materials, electronic components, and signage.

UV LED boards also find applications in the horticulture industry. By emitting UV light in specific wavelengths, these boards can enhance plant growth and development. UV light has been found to stimulate the production of essential plant compounds, such as anthocyanins and flavonoids, which contribute to plant coloration and resilience. Additionally, UV light can inhibit the growth of pests and molds, reducing the need for chemical pesticides. With the use of UV LED boards, farmers and horticulturists can achieve higher crop yields and deliver healthier, organically grown produce.

The versatility of UV LED boards expands even further as they prove valuable in the field of art conservation. UV light helps to identify hidden layers of paint and reveal the original colors and details of a painting. When UV LED boards are utilized in art restoration, conservators can make more informed decisions regarding cleaning, consolidation, and retouching. This technology has revolutionized the way art restoration is carried out, allowing for more accurate and precise preservation of cultural heritage.

In conclusion, UV LED boards manufactured by Tianhui have unveiled a realm of possibilities across various industries. With their energy efficiency, these cutting-edge boards help reduce costs and promote sustainability. From healthcare to printing, horticulture to art conservation, the applications of UV LED boards are vast and varied. By harnessing the power of UV light, these boards offer enhanced performance, increased productivity, and improved outcomes. It is clear that UV LED boards have the potential to reshape industries and pave the way for a brighter, more efficient future.

Enhancing Performance and Efficiency with UV LED Boards: Key Benefits Explored

In the world of advanced technology, there is a constant need for innovative solutions that can enhance performance and efficiency across various industries. UV LED boards, a cutting-edge technology developed by Tianhui, have emerged as a game-changer in achieving optimal outcomes. This article dives deep into the advantages and applications of UV LED boards, highlighting how they can revolutionize processes and pave the way for a more productive future.

1. What are UV LED Boards?

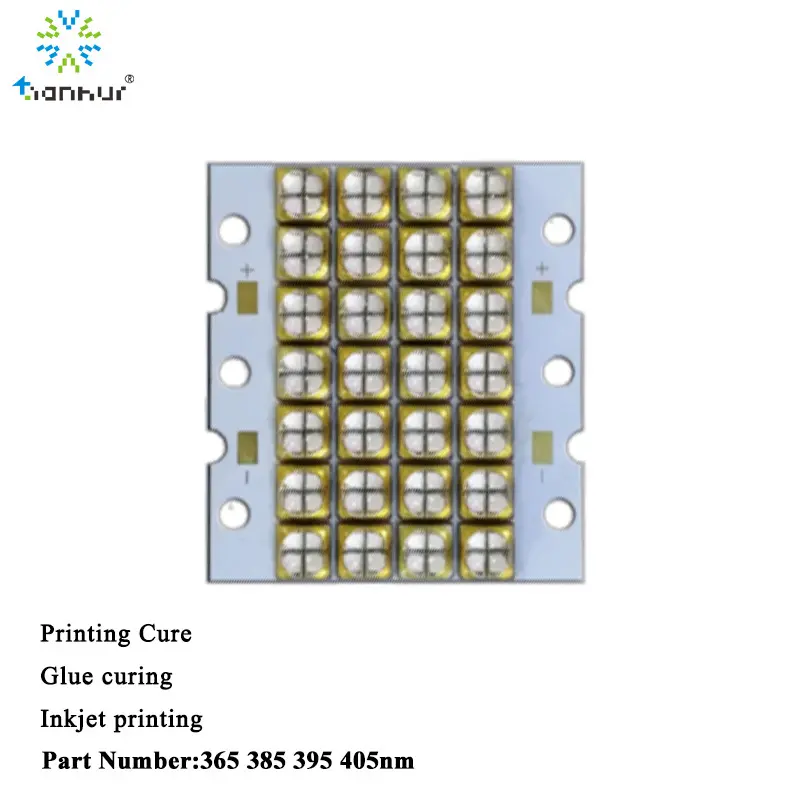

UV LED boards are compact, high-performance light sources that emit ultraviolet (UV) light. Unlike traditional UV lamps, they utilize light-emitting diodes (LEDs) to generate UV radiation. Tianhui's UV LED boards offer superior performance and longevity, making them ideal for a wide range of applications.

2. Key Benefits of UV LED Boards:

2.1. Energy Efficiency: UV LED boards consume significantly less energy compared to conventional UV lamps. This energy efficiency translates into reduced operating costs and a smaller carbon footprint, making them an environmentally-friendly choice.

2.2. Enhanced Performance: UV LED boards provide precise and consistent UV light output, resulting in improved performance and reliability. Their instant on/off capabilities ensure quick and efficient production cycles, reducing downtime and increasing productivity.

2.3. Extended Lifespan: With a lifespan of up to 40,000 hours, UV LED boards outshine traditional UV lamps in durability. This longevity minimizes the need for frequent replacements, leading to cost savings and uninterrupted operations.

2.4. Compact Size: UV LED boards are compact and lightweight, allowing for flexible installation in various settings. Their small form factor makes them easy to integrate into existing systems, without requiring extensive modifications.

2.5. Low Maintenance: Unlike traditional UV lamps, UV LED boards do not require warm-up or cool-down times, eliminating the need for complex maintenance procedures. Additionally, they do not contain hazardous substances such as mercury, reducing safety concerns and disposal challenges.

3. Applications of UV LED Boards:

3.1. Printing and Packaging: UV LED boards are widely used in the printing and packaging industry for curing inks and coatings. Their precise wavelength control ensures optimal curing, resulting in vibrant and durable prints. The instant on/off capabilities enable faster production speeds and reduced waste.

3.2. Electronics Manufacturing: UV LED boards play a crucial role in the manufacturing of electronic components. They are used for solder mask curing, circuit board printing, and adhesive bonding. The consistent UV light output ensures uniform curing, improving the quality and reliability of electronic devices.

3.3. Sterilization and Disinfection: UV LED boards are highly effective in sterilizing and disinfecting surfaces, air, and water. Their ability to emit specific wavelengths of UV radiation enables the eradication of bacteria, viruses, and other harmful microorganisms. This makes them invaluable in healthcare facilities, laboratories, and water treatment plants.

3.4. Horticulture: UV LED boards are utilized in the field of horticulture for enhancing plant growth and improving crop yield. The controlled emission of UV light promotes photosynthesis and triggers specific plant responses, leading to healthier and more productive vegetation.

In conclusion, UV LED boards developed by Tianhui offer numerous benefits that can significantly enhance performance and efficiency across various industries. Their energy efficiency, extended lifespan, compact size, and low maintenance requirements make them a cost-effective and sustainable choice. From printing and packaging to electronics manufacturing, sterilization to horticulture, the applications of UV LED boards are wide-ranging and promising. Embracing this cutting-edge technology has the potential to revolutionize processes and lead the way towards a more productive and sustainable future.

Exploring the Potential for UV LED Boards in Emerging Technologies

In today's technological landscape, innovation is constantly reshaping various industries. One such breakthrough that has gained significant attention is UV LED boards. These cutting-edge boards, developed by Tianhui, have the potential to revolutionize numerous sectors by harnessing the power of ultraviolet light.

The UV LED board is a remarkable technology that utilizes ultraviolet light-emitting diodes (LEDs) to provide intense illumination. Unlike conventional light sources, these boards emit UV light in a specific range of wavelengths, ranging from 100 to 400 nanometers. With their unique capabilities, UV LED boards offer a plethora of advantages and applications across various industries.

One key advantage of UV LED boards is their energy efficiency. These boards consume significantly less power compared to traditional lighting sources, translating into reduced energy costs for users. Additionally, UV LED boards have a considerably longer lifespan, ensuring minimal maintenance and replacement expenses. With their exceptional energy efficiency, UV LED boards enable sustainable and cost-effective solutions for businesses and industries alike.

The applications of UV LED boards are vast and diverse. One prominent field that stands to benefit immensely from this technology is the healthcare sector. UV light has proven to be highly effective in disinfection and sterilization processes, making UV LED boards valuable assets in hospitals, laboratories, and other healthcare settings. These boards can quickly sterilize surfaces and eliminate harmful bacteria, viruses, and other pathogens, thereby promoting a safer environment for patients and medical professionals.

Moreover, UV LED boards are increasingly being utilized in the agriculture industry. By emitting specific wavelengths of UV light, these boards have the potential to enhance plant growth and increase crop yield. UV light can stimulate plant growth factors and aid in pest control, enabling farmers to produce healthier crops with fewer chemical inputs. This environmentally friendly approach not only benefits the agricultural sector but also contributes to sustainable practices and healthier food production.

Another remarkable application of UV LED boards lies in the field of electronics. With the rapid advancement of technology, the miniaturization of electronic components is an ongoing trend. UV LED boards can be utilized in the manufacturing process of microelectronics, ensuring precise and accurate assembly. The focused UV light emitted by these boards facilitates the bonding and curing of adhesives and coatings at a microscopic level, enabling the production and advancement of cutting-edge electronic devices.

Furthermore, the UV LED boards developed by Tianhui hold great potential in the field of printing and imaging. These boards can be utilized in 3D printing processes, enabling faster and more efficient curing of UV-sensitive resins and polymers. This breakthrough enables the production of intricate and detailed 3D printed objects with enhanced precision. Moreover, UV LED boards can also be utilized in high-resolution imaging applications to improve image quality and ensure accurate color reproduction.

In conclusion, UV LED boards developed by Tianhui offer unparalleled advantages and applications in emerging technologies. With their energy efficiency, longevity, and vast range of applications, these boards have the potential to transform various industries. Whether it be in healthcare, agriculture, electronics, or printing, UV LED boards provide innovative solutions for enhanced performance and sustainable practices. As technological advancements continue to shape our world, the potential for UV LED boards in emerging technologies becomes increasingly evident.

Innovations in UV LED Technology: Future Prospects and Implications for Industries

In recent years, UV LED technology has emerged as a groundbreaking innovation with wide-ranging implications. As industries seek to enhance their performance and efficiency, UV LED boards have become a popular choice due to their numerous advantages and future prospects. This article aims to delve into the world of UV LED boards, with a focus on the advancements made by Tianhui, a leading brand in UV LED technology.

Advantages of UV LED Boards:

UV LED boards offer several advantages over conventional lighting solutions. Firstly, they are highly energy-efficient, consuming significantly less power while ensuring high output and long operational life. This reduced power consumption translates into cost savings for industries, making UV LED boards an economically viable solution.

Moreover, UV LED boards generate minimal heat, eliminating the need for additional cooling systems. This not only saves energy but also reduces the risks associated with overheating, enhancing safety measures in various industrial applications. Additionally, UV LED boards are compact and lightweight, allowing for easy integration into existing machinery or equipment.

Applications of UV LED Boards:

UV LED boards find extensive applications across diverse industries. One significant use is in the field of curing and drying processes. UV light emitted by these boards initiates photochemical reactions in substances like inks, adhesives, and coatings. This enables rapid curing, resulting in improved productivity and reduced production time. Industries such as printing, automotive, electronics, and packaging greatly benefit from the efficiency and performance offered by UV LED boards.

Another prominent application is in the field of sterilization and disinfection. UV light with a specific wavelength has the ability to deactivate bacteria, viruses, and other pathogens, making UV LED boards a valuable tool in healthcare facilities, laboratories, and food processing industries. The ability to eliminate harmful microorganisms without the use of chemicals makes UV LED boards an eco-friendly choice for maintaining hygiene and preventing contamination.

Future Prospects and Implications for Industries:

The future prospects of UV LED boards are promising, with ongoing research and development focused on enhancing their efficacy and expanding their applications. Tianhui, as a leading brand in UV LED technology, is at the forefront of these innovations.

Tianhui has invested substantial resources in optimizing the performance of their UV LED boards through advancements in chip technology, cooling systems, and wavelength control. These developments have resulted in UV LED boards with higher intensity, broader spectral ranges, and greater flexibility in use.

With the continuous improvement in UV LED technology, the implications for industries are vast. The adoption of UV LED boards can revolutionize various sectors, including printing, automotive, healthcare, and agriculture. Reduced production time, increased efficiency, and enhanced safety measures are just some of the benefits that these industry sectors can achieve by implementing UV LED boards into their operations.

UV LED boards offer a cutting-edge technology that has the potential to revolutionize industries by providing enhanced performance and efficiency. Tianhui, a market leader in UV LED technology, is at the forefront of this innovation with their advancements in chip technology and wavelength control. By considering the advantages and applications of UV LED boards, industries can harness their potential and look forward to a future marked by increased productivity, cost savings, and enhanced safety measures.

Conclusion

In conclusion, the utilization of UV LED boards has truly revolutionized various industries and holds immense potential for enhancing performance. The advantages and applications discussed in this article shed light on the multifaceted benefits of this cutting-edge technology. As a company with 20 years of experience in the industry, we fully recognize the significance of staying ahead of the curve and embracing innovative solutions. With the incorporation of UV LED boards, businesses can expect higher efficiency levels, increased durability, and improved environmental friendliness. From disinfection and sterilization processes to advanced printing techniques and beyond, the applications of UV LED boards are vast and versatile. As we continue to witness technological advancements and ever-evolving customer demands, it is crucial for all industry players to embrace such advancements to remain competitive. Embracing UV LED boards is not only a game-changer; it is a defining step towards achieving enhanced performance and paving the way for a prosperous future in a wide range of sectors. Let us embrace this cutting-edge technology and unlock its full potential for unprecedented growth and success.