Exploring The Wonders Of 385 Nm UV LED Technology

Welcome to the fascinating world of 385 nm UV LED technology! In this article, we will delve into the wonders of this cutting-edge technology and explore its numerous applications and benefits. From sterilization and disinfection to counterfeit detection and beyond, the potential of 385 nm UV LED technology is truly remarkable. Join us as we uncover the endless possibilities of this exciting innovation and learn how it is revolutionizing various industries. Whether you're a technology enthusiast or simply curious about the latest advancements, this article is sure to captivate your interest. So, come along as we embark on a journey to discover the incredible potential of 385 nm UV LED technology.

- Understanding the Basics of 385 nm UV LED Technology

UV LED technology has been gaining popularity in recent years due to its numerous applications in various industries such as medical, industrial, and consumer electronics. One particular wavelength of UV LED that has been making waves in the industry is the 385 nm UV LED. In this article, we will delve into the basics of 385 nm UV LED technology and explore its potential uses and benefits.

To begin with, it is important to understand that the term "385 nm" refers to the wavelength of the UV light emitted by the LED. UV light is categorized into different wavelength ranges, and 385 nm falls into the UVA range, which is commonly referred to as long-wave UV. This particular wavelength is known for its ability to induce fluorescence in certain materials, making it ideal for various applications.

One of the key advantages of 385 nm UV LED technology is its ability to excite and activate certain compounds and materials. This makes it highly suitable for applications such as UV curing, where it can be used to cure adhesives, coatings, and inks. Additionally, 385 nm UV LED technology is also used in the field of fluorescence microscopy, where it enables the visualization of specific cellular structures and molecules.

Another important aspect of 385 nm UV LED technology is its potential use in sterilization and disinfection processes. The 385 nm wavelength has been found to be effective in killing bacteria, viruses, and other microorganisms, making it a promising technology for applications in healthcare, food processing, and water treatment. With its ability to disinfect without harmful chemicals, 385 nm UV LED technology offers a safer and more environmentally friendly alternative to traditional sterilization methods.

Furthermore, 385 nm UV LED technology has also found applications in the field of counterfeit detection and security marking. The unique properties of the 385 nm wavelength make it well-suited for authentication and verification purposes, allowing for the detection of hidden security features and markings on a wide range of products and documents.

In conclusion, 385 nm UV LED technology holds immense potential for a wide range of applications, from industrial processes to healthcare and security. Its ability to induce fluorescence, its effectiveness in sterilization, and its use in counterfeit detection make it a versatile and valuable technology in today's world. As research and development in UV LED technology continue to advance, we can expect to see even more innovative uses for 385 nm UV LED in the future.

- Applications of 385 nm UV LED Technology

In recent years, 385 nm UV LED technology has gained significant attention for its wide range of applications in various industries. This cutting-edge technology has revolutionized the way UV light is utilized, offering more efficient, cost-effective, and environmentally friendly solutions. From sterilization and disinfection to curing and detection, the possibilities are endless with 385 nm UV LED technology.

One of the most prominent applications of 385 nm UV LED technology is in the field of sterilization and disinfection. With its high-energy output and precise wavelength, 385 nm UV LED light is highly effective in destroying bacteria, viruses, and other microorganisms. This makes it an ideal solution for water treatment, air purification, and surface disinfection in hospitals, laboratories, and food processing facilities. The ability of 385 nm UV LED technology to effectively eliminate harmful pathogens without the use of harmful chemicals makes it a highly desirable option for promoting public health and safety.

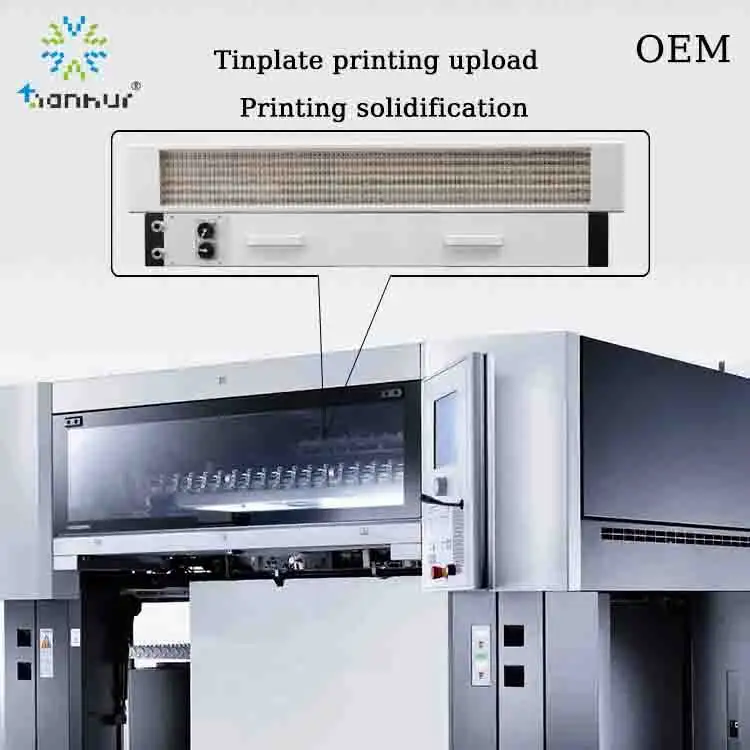

Another key application of 385 nm UV LED technology is in the field of curing. UV curing has become an integral part of various manufacturing processes, such as printing, coating, and bonding. The use of 385 nm UV LED light for curing offers several advantages over traditional mercury-based UV lamps, including lower energy consumption, longer lifespan, and instant on/off capability. This not only improves operational efficiency but also reduces the environmental impact associated with UV curing processes. As a result, 385 nm UV LED technology has become the preferred choice for manufacturers looking to enhance their production capabilities while minimizing their carbon footprint.

In addition to sterilization and curing, 385 nm UV LED technology is also widely used for detection and analysis purposes. The precise wavelength of 385 nm UV light makes it ideal for fluorescence-based detection methods, such as chromatography, spectrometry, and forensics. Its ability to excite specific compounds and molecules enables accurate and sensitive analysis in various scientific and industrial applications. Furthermore, the compact size and low power consumption of 385 nm UV LED devices make them suitable for portable and field-deployable instrumentation, expanding their potential in research and diagnostic fields.

With the advancements in 385 nm UV LED technology, the possibilities for its applications continue to grow. From medical devices and consumer electronics to environmental monitoring and security systems, the demand for 385 nm UV LED solutions is expected to increase across diverse industries. As the technology continues to evolve, it is likely to open up new opportunities for innovation and development, driving further advancements in UV technology and expanding its impact on society.

In conclusion, 385 nm UV LED technology has demonstrated its versatility and effectiveness in various applications, ranging from sterilization and curing to detection and analysis. Its unique capabilities, combined with its energy efficiency and environmental benefits, have positioned it as a powerful tool for addressing complex challenges across different industries. As the demand for UV LED solutions continues to rise, the potential for 385 nm UV LED technology to transform and improve various aspects of our lives is indeed a wonder worth exploring.

- Advantages of 385 nm UV LED Technology over Traditional UV Sources

UV LED technology has been taking the world by storm, offering numerous advantages over traditional UV sources. In particular, the 385 nm UV LED technology has been gaining attention for its exceptional capabilities and benefits. This article aims to explore the wonders of 385 nm UV LED technology and delve into the advantages it holds over conventional UV sources.

To begin with, it is important to understand the significance of the specific wavelength, 385 nm, in UV LED technology. This wavelength falls within the UVA spectrum, which ranges from 320 to 400 nm. UVA light is known for its ability to induce fluorescence in various materials, making it an invaluable tool in countless applications. The 385 nm wavelength, in particular, offers a balance between energy output and photoreactivity, making it highly effective for a wide range of uses.

One of the primary advantages of 385 nm UV LED technology over traditional UV sources is its energy efficiency. UV LEDs consume significantly less power compared to conventional UV lamps, resulting in lower operating costs and reduced energy consumption. This not only translates to cost savings for users but also contributes to environmental sustainability by reducing overall energy usage.

Furthermore, 385 nm UV LED technology boasts a longer lifespan than traditional UV sources. UV LEDs have a much longer operational life, often exceeding 20,000 hours of continuous use. This prolonged lifespan leads to lower maintenance requirements and replacement costs, as UV LEDs do not need frequent bulb changes or intricate servicing.

In addition to energy efficiency and extended lifespan, 385 nm UV LED technology offers improved control and precision in UV curing and other applications. UV LEDs can be easily modulated to deliver specific intensity and dosage, allowing for precise curing and irradiation processes. This level of control is often unmatched by traditional UV sources, offering users a greater degree of flexibility and customization in their operations.

Another significant advantage of 385 nm UV LED technology is its reduced heat output. Traditional UV lamps generate substantial heat during operation, which can be problematic in certain applications. UV LEDs, on the other hand, produce minimal heat, making them suitable for use in heat-sensitive materials and environments.

Moreover, 385 nm UV LED technology is inherently safer than traditional UV sources. UV LEDs do not contain harmful mercury, unlike many traditional UV lamps, eliminating the associated health and environmental risks. This makes UV LEDs a safer and more sustainable choice for various industries and applications.

In conclusion, the advantages of 385 nm UV LED technology over traditional UV sources are clear and compelling. From energy efficiency and extended lifespan to improved control and safety, UV LEDs are revolutionizing the way UV light is utilized across industries. As this technology continues to advance, it is expected to further expand its capabilities and applications, making it an indispensable tool for numerous fields.

- Potential Future Developments in 385 nm UV LED Technology

Exploring the Wonders of 385 nm UV LED Technology - Potential Future Developments in 385 nm UV LED Technology

UV LED technology has advanced significantly in recent years, and one of the most promising developments is the 385 nm UV LED. This specific wavelength offers a wide range of potential applications, from medical and healthcare to sterilization and industrial processes. In this article, we will explore the potential future developments in 385 nm UV LED technology and the impact it could have on various industries.

The 385 nm UV LED is a type of ultraviolet light-emitting diode that emits light at a wavelength of 385 nanometers. This particular wavelength falls within the UVA spectrum, which is known for its ability to penetrate the skin and other materials. As a result, 385 nm UV LED technology has the potential to revolutionize a wide range of industries.

One of the most exciting potential future developments in 385 nm UV LED technology is its use in medical and healthcare applications. Research has shown that 385 nm UV light has antimicrobial properties, making it effective in killing bacteria, viruses, and other pathogens. This could lead to the development of UV LED devices for disinfecting medical equipment, sterilizing medical facilities, and even treating skin conditions such as psoriasis and eczema.

In addition to medical and healthcare applications, 385 nm UV LED technology also has the potential to revolutionize the sterilization and disinfection industry. Traditional methods of sterilization, such as chemical disinfectants and heat treatment, can be time-consuming and potentially harmful to the environment. UV LED technology offers a more efficient and environmentally friendly alternative, as 385 nm UV light can effectively kill a wide range of microorganisms without the use of harsh chemicals or excessive heat.

Furthermore, the potential future developments in 385 nm UV LED technology could also have a significant impact on industrial processes. For example, UV LED technology could be used for curing adhesives, coatings, and inks in manufacturing processes, as well as for detecting and preventing counterfeit products. The use of 385 nm UV LED technology in these applications could lead to improved product quality, reduced production times, and lower energy consumption.

As with any emerging technology, there are still challenges to be overcome before 385 nm UV LED technology can reach its full potential. For example, researchers and engineers are currently working to improve the efficiency and reliability of 385 nm UV LED devices, as well as to develop cost-effective manufacturing processes. However, the potential benefits of this technology are so significant that it is likely only a matter of time before these challenges are overcome.

In conclusion, the potential future developments in 385 nm UV LED technology have the potential to transform a wide range of industries, from medical and healthcare to sterilization and industrial processes. As research and development in this field continue to progress, we can expect to see an increasing number of innovative applications for this technology, ultimately leading to a safer and more sustainable future.

- The Environmental and Economic Impact of 385 nm UV LED Technology

In recent years, the development of UV LED technology has been gaining significant attention, particularly the 385 nm wavelength. This article aims to explore the environmental and economic impact of this technology, shedding light on its potential benefits and implications for various industries.

To begin with, the environmental impact of 385 nm UV LED technology is noteworthy. Unlike traditional UV lamps, UV LED technology consumes significantly less energy and has a longer lifespan, leading to reduced carbon emissions and overall environmental footprint. Additionally, UV LEDs do not contain harmful mercury, which is a common component in traditional UV lamps, making them more environmentally friendly and safe to dispose of at the end of their lifespan. This shift towards UV LED technology aligns with global efforts to support sustainable practices and reduce environmental impact.

From an economic perspective, the adoption of 385 nm UV LED technology has the potential to drive cost savings across different sectors. The energy efficiency of UV LEDs translates to lower operating costs, making them an attractive option for businesses looking to optimize their processes and reduce expenses. Furthermore, the extended lifespan of UV LEDs means that less frequent replacement and maintenance are required, leading to additional cost savings in the long run. This economic advantage positions UV LED technology as a valuable investment for industries seeking to improve their bottom line while embracing innovative solutions.

In the realm of healthcare and sanitation, 385 nm UV LED technology has the potential to revolutionize the disinfection process. The specific wavelength of 385 nm is effective in deactivating bacteria, viruses, and other pathogens, making it a powerful tool for sterilization and sanitation in medical facilities, laboratories, and other critical environments. By harnessing the power of UV LED technology, these industries can enhance their infection control protocols and contribute to the overall improvement of public health.

Furthermore, the impact of 385 nm UV LED technology extends to the manufacturing and production sectors. The precise and controlled nature of UV LED technology makes it an ideal solution for curing and bonding applications, offering faster processing times and improved product quality. This has the potential to streamline production processes and increase overall efficiency, ultimately leading to cost savings and enhanced productivity.

In conclusion, the exploration of 385 nm UV LED technology unveils its significant environmental and economic impact across various industries. With its energy efficiency, prolonged lifespan, and effectiveness in disinfection and production processes, UV LED technology presents itself as a sustainable and cost-effective solution for businesses and organizations. As the demand for environmentally conscious and economically viable solutions continues to rise, the potential of 385 nm UV LED technology to reshape industries and contribute to a more sustainable future is undeniable.

Conclusion

In conclusion, the exploration of 385 nm UV LED technology has opened up a world of possibilities for various industries. With over 20 years of experience in the industry, our company has witnessed the incredible advancements in UV LED technology and has been at the forefront of implementing these innovations into our products and services. As we continue to push the boundaries of what is possible with UV LED technology, we are excited to see how it will revolutionize processes and products in the future. The wonders of 385 nm UV LED technology are truly endless, and we look forward to being a part of the continued exploration and application of this remarkable technology.