Tianhui - jeden z popredných výrobcov a dodávateľov UV LED čipov poskytuje ODM / OEM UV LED čipy už viac ako 22 rokov.

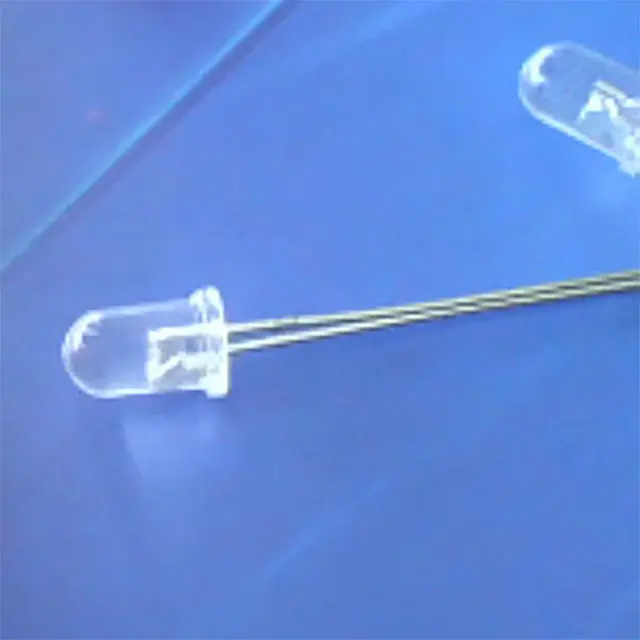

Predstavenie a vlastnosti produktu s infračervenou LED lampou

2022-12-16

Tianhui

89

Infračervená svetelná dióda (LED) je zariadenie vyžarujúce blízke infračervené svetlo, ktoré premieňa elektrickú energiu na svetelnú energiu. Má rad výhod, ako sú malé rozmery, nízka spotreba energie a dobré smerovanie. , Optoelektronické riadenie, sledovanie cieľa a ďalšie systémy, ktoré sa vyznačujú nízkou spotrebou energie a malým objemom. Je to dióda, ktorú budeme používať denne. Veľa pozornosti sa stále venuje výberu infračervenej LED. Charakteristiky a aplikácie lampových guľôčok, však? Charakteristiky infračervených LED lámp sa široko používajú v infračervených diaľkových ovládačoch vo farebných televízoroch, audio systémoch a rôznych domácich spotrebičoch. Ovládacia vzdialenosť diaľkového ovládača môže vo všeobecnosti dosiahnuť 6 až 8 metrov, čo je veľmi pohodlné na používanie. Pretože metóda infračerveného diaľkového ovládania je veľká, jej infračervený spúšťací a prijímací obvod má kompletné podporné zariadenia. Tieto zariadenia sú nielen lacné a spoľahlivé a obvod je mimoriadne jednoduchý. Elektroničtí nadšenci môžu tieto zariadenia využiť na zostavenie diaľkových ovládačov rôzneho účelu, ktoré sú nielen praktické, ale zároveň zvyšujú ich záujem o výrobu. Charakteristiky korálkov infračervenej LED lampy sú neviditeľné a ľudské oči si ich nedokážu uvedomiť. Bežne používané infračervené LED lampy sú podobné bežným LED lampám. Skvelý môže byť aj klesajúci pomer obsadenia pulzu. Bežná dióda vyžarujúca infračervené svetlo, jej výkon je rozdelený do troch kategórií: malý výkon (1MW 10MW), stredný výkon (20MW 50MW) a vysokovýkonný LED (50mW 100MW alebo viac). Pri použití rôznych výkonových infračervených diód vyžarujúcich svetlo by sa mal nakonfigurovať ovládač zodpovedajúceho výkonu. Aby sa vytvorila infračervená žiariaca dióda, stačí pridať určité frekvenčné impulzné napätie do hnacieho potrubia. Keď sú vlastnosti a aplikácia infračervených LED guľôčok vyžarované infračervenou diódou na ovládanie ovládaného zariadenia, v ovládacom zariadení sú zodpovedajúce infračervené fotoelektrické konverzné komponenty, ako je infračervená prijímacia dióda, fotoelektrický tranzistor atď. Existujú dva spôsoby infračervených prenosových trubíc a infračervených prijímacích trubíc. Priama sa vzťahuje na dva konce spustenia a ovládané optickou rúrkou a prijímacou trubicou a stredná vzdialenosť je určitá vzdialenosť v strede; odraz sa vzťahuje na optickú trubicu a prijímaciu trubicu spolu. Keď narazíte na reflex, prijímacia trubica prijíma infračervené lúče vrátené odrazom.

Autor: tianhui- Dezinfekcia vzduchu

Autor: tianhui- Uv led výrobcovia

Autor: tianhui- Dezinfekcia uv vody

Autor: tianhui- Uv led riešenie

Autor: tianhui- Uv led dióda

Autor: tianhui- Uv led diódy výrobcovia

Autor: tianhui- Uv led modul

Autor: tianhui- Uv led systém tlače

Autor: tianhui- UV LED pasca na komáre

Spojte sa s nami

Odporúčané články

žiadne dáta

Kontaktujte nás

Rýchle odkazy

Môžete nájsť Nás tu

Copyright © Zhuhai Tianhui Electronic Co., Ltd www.tianhui-led.com |

Mapa stránky

Kontaktuj nás

Zanechajte dotaz, poskytneme vám kvalitné produkty a služby!

Customer service

We use cookies to ensure that we give you the best experience on and off our website. please review our zásady ochrany osobných údajov

Reject

Nastavenia súborov cookie

Dohodnite sa teraz

Vaše základné informácie, online prevádzkové správanie, informácie o transakciách, prístupové údaje sú potrebné na to, aby vám ponúkli náš normálny nákup, transakcie a doručovacie služby. Odstúpenie tohto povolenia bude mať za následok neúspech nakupovania alebo dokonca k ochrnutiu vášho účtu.

Vaše základné informácie, online prevádzkové správanie, informácie o transakciách, údaje o prístupu majú veľký význam na zlepšenie konštrukcie webových stránok a zlepšenie zážitku z nákupu.

Vaše základné informácie, online prevádzkové správanie, informácie o transakciách, preferenčné údaje, údaje o interakcii, údaje o prognóze a prístupové údaje sa použijú na účely reklamy odporúčaním produktov vhodnejších pre vás.

Tieto súbory cookie nám hovoria, ako používate stránku a pomáhajú nám, aby ste ju zlepšili. Napríklad tieto súbory cookie nám umožňujú spočítať počet návštevníkov našej webovej stránky a vedieť, ako sa návštevníci pri používaní pohybujú okolo. To nám pomáha vylepšiť, ako naše stránky fungujú. Napríklad zabezpečením toho, aby používatelia našli to, čo hľadajú, a že čas načítania každej stránky nie je príliš dlhý.